uv hot melt adhesive

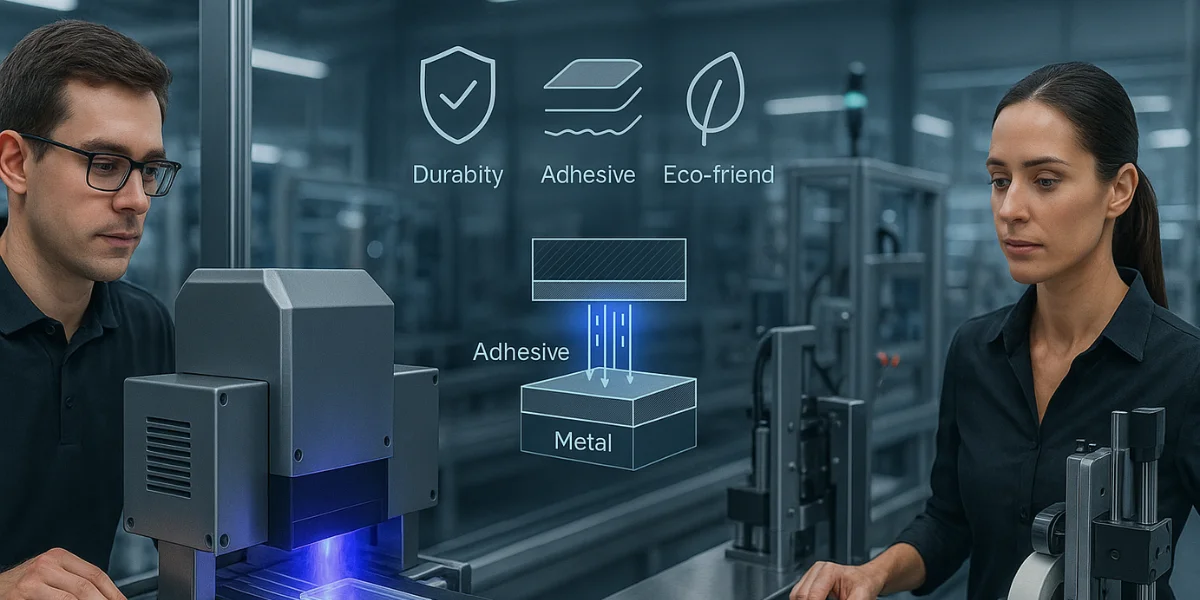

UV hot melt adhesive technology has transformed modern adhesive bonding by combining the fast processing of hot melt adhesive glue with the durability of UV curable adhesives. These advanced solutions activate instantly under ultraviolet energy, enabling superior performance across industries. Compared to traditional methods, they offer higher hot melt adhesive temperature resistance and exceptional reliability. With growing demand for efficient adhesive applications, uv adhesive manufacturers in India are delivering high-performance solutions for automotive, electronics, medical, and packaging sectors. Hot melt adhesive uses continue to expand as industries adopt cleaner, faster, and more durable adhesive bonding processes.adhesive applications

Modern adhesive applications have evolved dramatically with the rise of UV hot melt adhesive solutions. These systems outperform traditional glues by offering instant curing under ultraviolet energy, making them ideal for precision assembly and high-speed manufacturing lines. They deliver strong adhesive bonding, superior chemical resistance, and stability across varied hot melt adhesive temperature conditions. Whether for labels, electronics, medical products, or automotive assemblies, hot melt adhesive uses continue to expand. With the growth of hot melt adhesive manufacturers and innovative uv adhesive manufacturers in India, industries now achieve cleaner, faster, and more durable adhesive bonding processes than ever before.uv curable adhesives

UV curable adhesives have become a breakthrough in industrial bonding due to their ability to cure instantly when exposed to ultraviolet energy. These adhesives combine the viscosity and flexibility of hot melt adhesive glue with the strength of crosslinked polymers. Designed to withstand extreme hot melt adhesive temperature conditions, they excel in electronics, medical devices, packaging, and automotive systems. Industries depend on these formulations for precise adhesive applications requiring clarity, durability, and stability. As uv adhesive manufacturers in India continue to innovate, more manufacturers are adopting UV hot melt adhesive systems for reliable, efficient, and eco-friendly adhesive bonding.adhesive manufacturers

Leading adhesive manufacturers are shifting toward hybrid bonding systems that combine traditional hot melt technology with advanced UV curing. These manufacturers create adhesives that deliver strong adhesive bonding, fast setting, and high resistance to hot melt adhesive temperature fluctuations. By collaborating with top uv adhesive manufacturers in India, they now offer a wide range of UV curable adhesives suitable for automotive, electronics, medical, and packaging sectors. Their formulations enhance adhesive applications by improving durability, efficiency, and sustainability. As demand grows globally, hot melt adhesive manufacturers are setting new standards in performance-driven adhesive bonding processes.hot melt adhesive manufacturers

Hot melt adhesive manufacturers have evolved to include UV-reactive systems that merge traditional bonding strength with fast UV curing capabilities. These manufacturers design adhesives that offer exceptional green strength, rapid processing, and superior resistance to variations in hot melt adhesive temperature. With innovations driven by uv adhesive manufacturers in India, these hybrid materials support advanced adhesive applications such as automotive interiors, electronics assembly, labels, and medical components. Their formulations enhance hot melt adhesive uses by integrating UV curable adhesives for higher performance and reliability. As efficiency demands rise, these manufacturers are shaping the future of industrial adhesive bonding processes.

7 Benefits of UV Hot Melt Adhesives: A Game Changer for Adhesive Applications

7 Benefits of UV Hot Melt Adhesives: A Game Changer for Adhesive Applications