Hot melt adhesive dispensers

Mahisa leads the industry in hot melt adhesive dispensers, setting a new standard in adhesive application technology. Our state-of-the-art hot melt machines deliver precision and efficiency in every application. With a commitment to quality, we source adhesives hot melt from the most trusted hot melt adhesive manufacturers in India, ensuring optimal performance and reliability. What sets us apart is our strategic collaboration with leading hot melt adhesive manufacturers in India, ensuring that we provide the best solutions for aluminum industrial applications. Our products include the advanced switched hot melt handgun, designed for precision and versatility in every application.

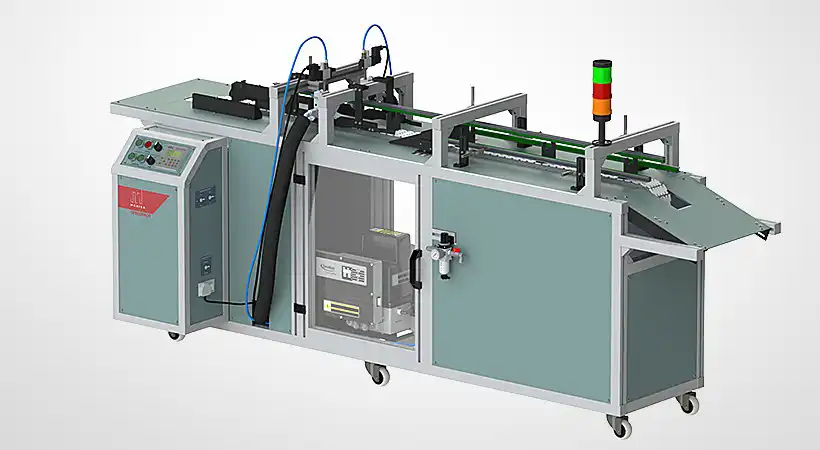

Hot melt dispenser machine

Mahisa’s hot melt adhesive dispensers are the epitome of precision and efficiency in adhesive application technology. Our glue dispensing machine manufacture ensures that every adhesive dispensing machine is meticulously designed to guarantee seamless operations across various industries. Whether it’s for intricate crafts or heavy-duty industrial applications, Mahisa’s hot melt machine dispensers deliver consistent and reliable performance. The advanced technology behind our machines, including the collaboration with Power Adhesives Tec, guarantees precise control over hot melt adhesive glue, facilitating impeccable bonding. Our products feature the hot melt handgun, providing versatility and precision in every application.

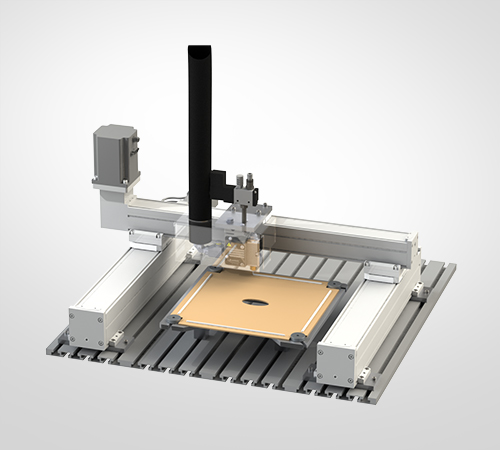

Glue dispenser

Mahisa’s glue dispenser machines set a gold standard in adhesive application technology. Our precision-engineered hot melt adhesive dispensers are adept at handling various industries’ intricate needs. The adhesive glue dispensed is of superior quality, ensuring robust adhesive bonding that stands the test of time. Our state-of-the-art machines, including the hot melt adhesive machine, are meticulously engineered to handle hot melt adhesive glue with utmost accuracy. We collaborate with trusted hot melt adhesive manufacturers, ensuring that our products meet the highest standards. Our hot melt glue applicator machine India is designed for versatility and precision, making it the ideal choice for a wide range of applications. Our partnership with Power Adhesives guarantees groundbreaking technology and performance.

Hot melt adhesive

Mahisa leads the industry with its cutting-edge hot melt adhesive dispensers, setting a new standard for precision in adhesive application. Our industrial adhesive dispenser units are engineered to handle hot melt adhesive and hot melt glue gun sticks with unparalleled accuracy. The adhesive unit ensures a flawless application, resulting in the strongest adhesive glue bonds. As one of the leading hot melt adhesive manufacturers in Mumbai, we provide innovative solutions for diverse industries. Our adhesive dispensing machine India meets the highest standards of performance, while our hot glue dispenser machine offers versatility and precision for various applications.

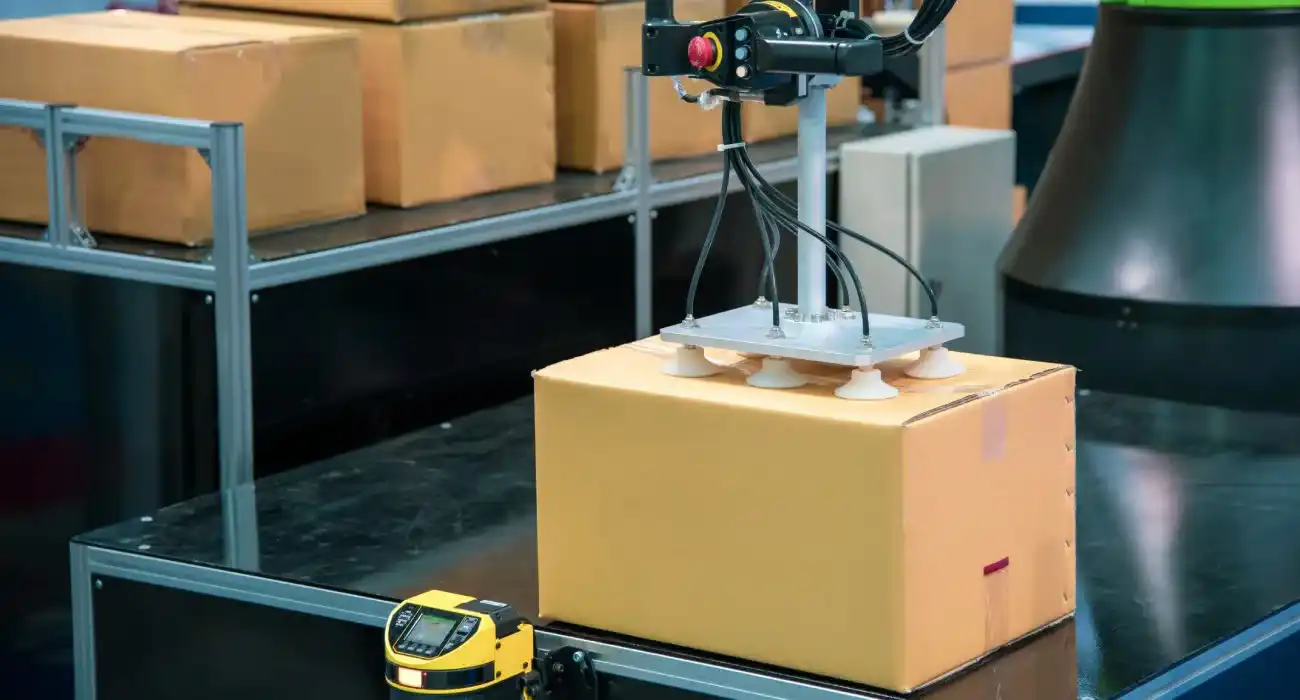

Adhesive dispenser machine

Mahisa stands at the forefront of adhesive application solutions with their cutting-edge adhesive dispenser machines. Partnering with leading hot melt adhesive manufacturers in India, Mahisa ensures top-quality hot melt powder is seamlessly handled by their dispensers. The integration of hot melt glue guns further enhances the application process, guaranteeing a flawless finish.

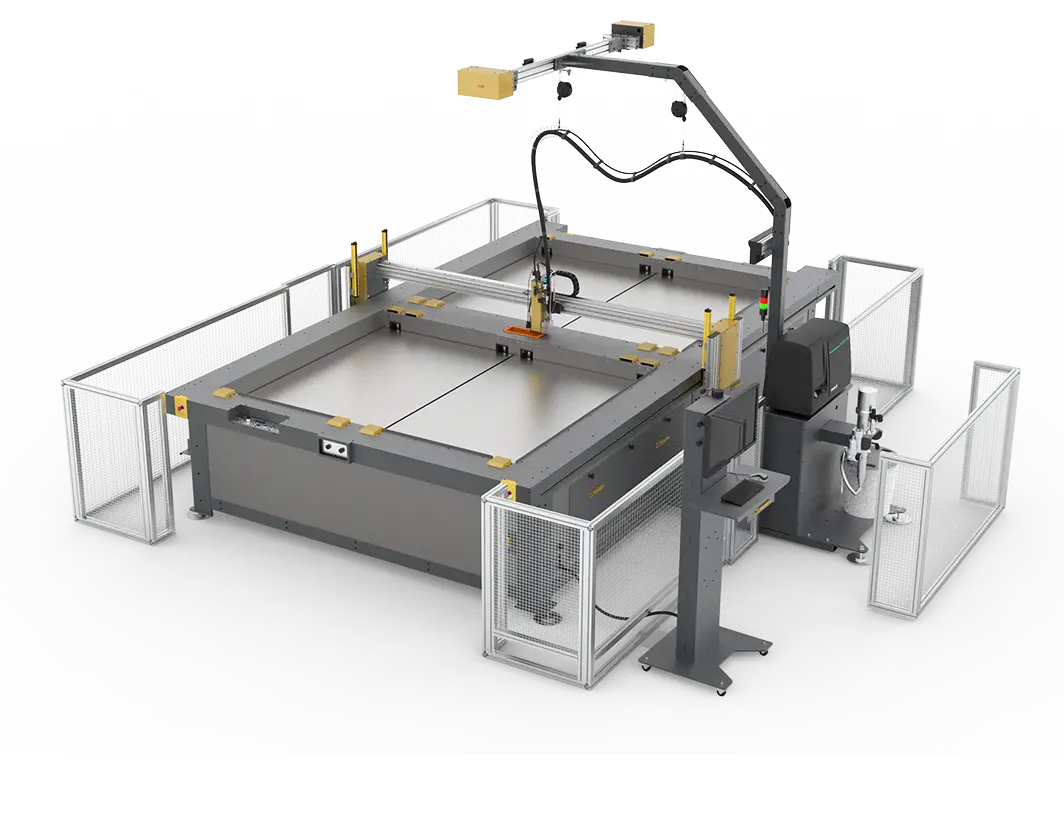

Hot melt gluing machine

Mahisa introduces a game-changing hot melt gluing machine, elevating adhesive dispensing technology to a new level of precision and efficiency. Our state-of-the-art adhesive dispensing machine is designed to handle a variety of applications with unmatched accuracy. Whether it’s intricate crafting or heavy-duty industrial tasks, Mahisa’s auto glue dispenser machine ensures seamless operations.

Hot melt glue

Mahisa leads the market in hot melt adhesive dispensers, showcasing unrivaled precision in adhesive application technology. Their industrial glue dispensers are adept at handling various applications, from intricate crafts to heavy-duty industrial projects. Mahisa’s advanced hot melt extrusion technology ensures seamless operations, guaranteeing a flawless adhesive application.

Hot melt machines

Mahisa sets the bar high with their state-of-the-art hot melt machines, revolutionizing adhesive application. Mahisa’s hot melt adhesive dispensers are a pinnacle of precision in adhesive application technology. These advanced machines seamlessly handle hot melt glue sticks with utmost accuracy. Employing the hot melt extrusion method, Mahisa ensures flawless operations across various industries. Trust Mahisa for top-tier adhesive application machines, where innovation meets excellence in every bond.

Industries We Serve with Hot Melt Adhesive Dispensers

Ideal for carton sealing, case sealing, and box sealing applications.

Used in component bonding, insulation attachment, and interior assembly.

Ensuring strong adhesion for edge banding, panel assembly, and laminations.

Delivering durable adhesive bonding for books, catalogs, and brochures.

Essential for electronics, appliances, and general product manufacturing.

Enabling precise adhesive application for labels, stickers, and pressure-sensitive adhesives.

Ensuring secure and tamper-proof packaging.

Ideal for assembling plastic, metal, and composite materials.

Ensuring precise adhesive application for labels and wraps.

Enhancing durability and strength in automotive manufacturing.

Providing long-lasting binding for books and printed materials.

Ensuring seamless lamination and wood bonding.

Why Choose Mahisa Packaging for Hot Melt Adhesive Dispensers?

Our hot melt glue application systems offer accurate adhesive placement.

Reduce operational costs with our advanced dispensing technology.

We offer tailored hot melt adhesive dispensing equipment to suit your needs.

Built for long-lasting performance, even in high-speed production environments.

What is a hot melt adhesive dispenser?

A hot melt adhesive dispenser is a machine designed for precise adhesive application, commonly used in industries like packaging, product assembly, woodworking, and automotive. It melts solid hot melt glue and dispenses it in controlled amounts for strong and durable bonding.

How does a hot melt adhesive machine work?

A hot melt adhesive machine heats solid glue sticks or pellets to a liquid state. The molten adhesive is then applied through a glue dispenser system, ensuring efficient and uniform bonding for various materials like plastic, wood, metal, and paper.

What industries use hot melt adhesive dispensers?

Hot melt adhesive dispensers are widely used in:

✓ Packaging Industry – Carton sealing, box sealing, and case packaging.

✓ Automotive Industry – Component bonding, insulation, and interior assembly.

✓ Woodworking & Furniture – Edge banding, panel lamination, and wood bonding.

✓ Product Assembly – Electronics, appliances, and consumer goods manufacturing.

✓ Bookbinding & Printing – Strong binding for books, catalogs, and brochures.

✓ Labeling & Tapes – Adhesive application for labels and stickers.

What are the advantages of using an adhesive dispenser machine?

✓ Efficient glue application for consistent and strong bonding.

✓ Reduces material waste by dispensing precise amounts of adhesive.

✓ Improves production speed with automated gluing processes.

✓ Works with various adhesives for different materials and applications.

Can hot melt glue be used for high-speed packaging automation?

Yes! Hot melt glue is widely used in high-speed packaging automation, ensuring secure carton sealing and tamper-proof packaging in food, beverage, and e-commerce packaging lines.

What is the best adhesive for various materials like plastic, metal, and wood?

Hot melt adhesives work well for bonding plastic, metal, wood, paper, and fabric. The right adhesive application machine ensures a strong bond based on material type and industry requirements.

How do I choose the right glue machine for my business?

Consider:

✓ Adhesive type (hot melt glue sticks, pellets, or granules).

✓ Application process (manual, semi-automatic, or fully automated).

✓ Industry requirements (packaging, automotive, woodworking, etc.).

✓ Production speed and volume needs.

Where can I buy a high-quality hot melt adhesive dispenser?

At Mahisa Packaging, we offer industrial hot melt glue machines tailored for various industries. Contact us for expert guidance on the best adhesive bonding solutions for your business.

Blogs You May Like..