Choosing the Right Adhesive for Strong and Durable Bonding

Choosing the Right Adhesive for Strong and Durable Bonding

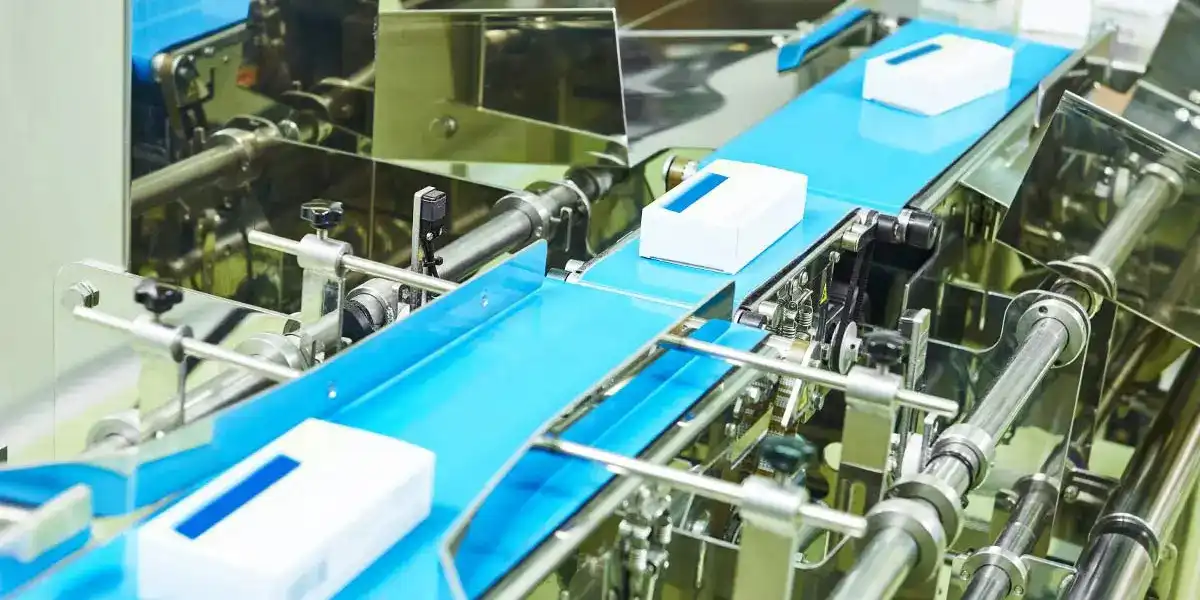

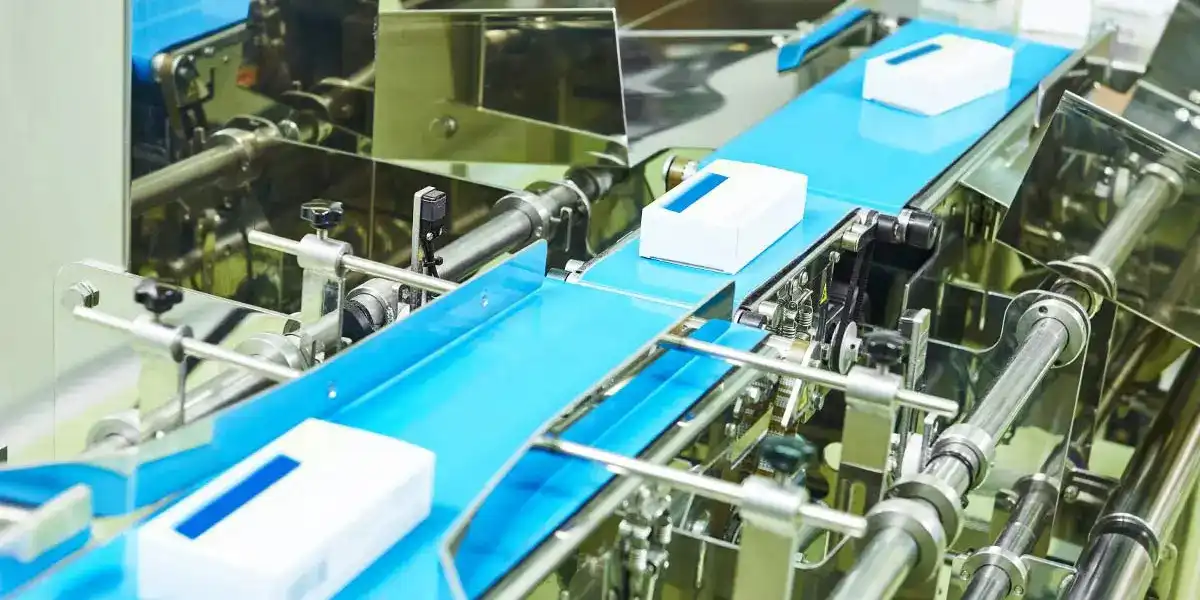

Adhesive for bonding has revolutionized the way materials are joined, offering a versatile and efficient solution for various applications. For adhesives for glass bonding, selecting a product designed for transparency and durability is essential to ensure a seamless and lasting connection. For adhesive for bonding metal to wood, choosing the right product is crucial to ensure a strong connection. Similarly, an adhesive for bonding aluminum must possess specific properties to cater to the lightweight yet sturdy nature of this metal. Adhesive metal solutions, including specialized adhesive metal glue, have been engineered to provide optimal strength and resilience, making them indispensable in both industrial and DIY projects. For more complex requirements, such as adhesive metal to plastic, it’s essential to select a product that can seamlessly adhere to both surfaces without compromising their integrity. The types of adhesive bonding available today offer tailored solutions for different materials, ensuring maximum effectiveness. To ensure precise application and reduce waste, many industries employ adhesive dispensing machines, which enhance efficiency and control in the bonding process. Flexible adhesives for bonding are valuable for materials that may experience movement or stress, maintaining strong bonds under challenging conditions. The strongest glue options available today meet such demands, offering unparalleled bonding strength and reliability. The adhesive property of these glues ensures they stick firmly, maintaining the bond even under stress and environmental challenges. Whether you need an adhesive for a simple home repair or a critical industrial application, understanding the nuances of each type of glue can significantly affect the success of your project. Embrace the power of adhesive for bonding and experience the ease and efficiency it brings to material joining tasks.

Super adhesive technology has revolutionized the way we approach various bonding tasks, offering unparalleled strength and versatility for different materials. Whether you’re using super adhesive for intricate craft projects or industrial applications, the results are consistently impressive. Strong adhesives for heavy duty tasks are particularly valued in industrial settings where durability and performance are critical. Adhesive tape, super adhesive, is widely appreciated for its convenience and effectiveness in temporary and permanent bonds. For those working with fabrics, adhesive fabric solutions provide a seamless way to join textiles without sewing. When searching for the best adhesive for any task, it’s crucial to consider the specific materials involved. For example, the strongest glue for plastic ensures a durable bond, essential for repairs and constructions involving synthetic materials. In more complex scenarios, such as bonding metal to wood, specialized adhesive for bonding these dissimilar materials is necessary to achieve a strong, lasting connection. Understanding adhesive bonding techniques can significantly improve the efficiency and effectiveness of these tasks, whether for everyday repairs or industrial applications. The adhesive strength for industrial use has reached new heights, offering solutions that cater to demanding applications, including heavy-duty repairs and construction tasks. Overall, the evolution of adhesive technologies has enabled us to create strong bonds quickly and efficiently, catering to both everyday needs and specialized industrial requirements. Whether it’s through adhesive tape for quick fixes or advanced super adhesive formulations for demanding applications, these products have become indispensable in our quest for durable bonds.

There are various types of adhesive bonding techniques used across industries to provide durable and efficient bonding solutions for different materials. A strong adhesive for bonding is essential for ensuring the integrity of the materials being joined, especially in demanding applications where strength is a priority. Adhesives for metal bonding are specifically planned to handle the unique properties of metals, offering resistance to environmental stress and ensuring a long-lasting hold. For woodworking projects, wood adhesives for bonding provide the perfect solution, offering a strong, flexible bond that works well with the natural expansion and contraction of wood. With plastics, plastic adhesives for bonding cater to the specific challenges of bonding non-porous, smooth plastic surfaces, providing strong and reliable joints without compromising the material’s integrity. Epoxy adhesives for bonding are known for their versatility and are often used in industrial applications because of their excellent adhesive strength and resistance to extreme temperatures and harsh conditions. For applications requiring even higher durability, high-strength bonding adhesives are employed, offering superior bonding capabilities in construction, automotive, and other heavy-duty applications. Last, industrial adhesives for bonding are specially designed for large-scale production environments, providing high performance, consistency, and efficiency in bonding a wide range of materials, from plastics to metals and composites.

Fabric adhesive glue is essential for sewing and crafting projects, providing a strong bond with no stitching. For metal-to-metal bonding, adhesive processes such as using metal adhesive glue offer robust and reliable connections, ideal for various industrial applications. For those looking to bond metal to plastic, metal, plastic adhesive serves as an effective solution, catering to diverse material combinations. To enhance precision and control in these bonding processes, adhesive dispensing machines play a pivotal role, especially in industrial settings where consistent application is crucial. There are various adhesive types available, each tailored to specific needs and surfaces, such as epoxies, cyanoacrylates, and polyurethanes. The properties of adhesive, including viscosity, setting time, and tensile strength, play a crucial role in determining its suitability for different applications. Choosing the best adhesive for bonding plastic to plastic often involves selecting products like cyanoacrylate or specialized plastic glues designed for high durability and flexibility. Adhesive joints formed with these products ensure a seamless connection between surfaces. Sticky glue is commonly used for quick fixes and temporary bonds, while cold glue is preferred for woodworking and other applications requiring a less aggressive adhesive. Understanding the different adhesive types and their properties ensures the right selection for any bonding requirement, whether it’s for fabric, metal, plastic, or other materials. This knowledge guarantees strong, lasting connections and enhances the overall quality and reliability of the project. The adhesion strength of the chosen adhesive plays a key role in determining the longevity and effectiveness of the bond, particularly for heavy-duty applications such as adhesive for metal to metal connections, which provide a strong bond ideal for industrial and construction applications.

Hot melt adhesive is a versatile and efficient bonding solution widely used in various applications, thanks to its quick setting and strong bonding capabilities. When selecting an adhesive for metal, it’s crucial to consider the bond strength and durability required, and hot melt adhesive excels in providing a robust bond for metal surfaces. Known for being one of the strongest adhesives, it can effectively serve as glue for metal, ensuring long-lasting bonds. For applications requiring plastic to metal adhesive, hot melt adhesive offers excellent adhesion, making it ideal for industrial and DIY projects. In scenarios where the strongest glue for plastic to plastic is needed, the hot melt adhesive stands out because of its strong bond and fast curing time. It is also highly effective as an adhesive for bonding rubber to concrete, ensuring that these different materials adhere securely. As a reliable adhesive, hot melt glue is used across various industries for its ease of use and superior bonding properties. Whether working with paper or heavier materials like metal and plastic, hot glue remains a top choice for achieving strong bonds, making it an indispensable tool in both commercial and residential settings. Silicone adhesives are often preferred for their flexibility and heat resistance in specialized applications, providing an alternative bonding solution for materials like rubber and plastic. For advanced applications, integrating an adhesive bonding system can improve consistency and efficiency, making it easier to achieve precise and secure bonds. The evolution of modern adhesives continues to introduce new solutions that address the diverse needs of industries, ensuring strong, reliable bonds for a wide range of materials.

Adhesives and bonding are essential for creating durable connections between various materials, from metal to metal glue, to more specialized applications. When seeking the strongest adhesive glue, it’s crucial to select the right adhesive material for the job, ensuring a robust and lasting bond. For metal-to-metal bonding, the strongest glue for metal, such as industrial-grade epoxy, offers superior strength and durability. Similarly, when bonding leather to plastic, a high-performance adhesive designed for such materials ensures a secure attachment without compromising the integrity of either surface. When working with aluminum, choosing an adhesive specifically planned for bonding aluminum provides a strong and reliable bond. For versatile applications, glue sticks offer convenience and ease of use, though they might not always match the strength of more specialized adhesives. By understanding the properties and uses of different adhesives, you can achieve optimal results in your bonding projects, whether you’re tackling heavy-duty metal connections or intricate leather-to-plastic applications. For adhesive for bonding leather to plastic, choose a strong, flexible adhesive designed for such materials. For adhesive for bonding aluminum, use a specialized adhesive that ensures a robust and lasting bond. Whether you’re working with adhesives and glues for everyday repairs or using industrial-strength adhesives for heavy-duty tasks, selecting the right adhesive for each specific need guarantees the success of your project.

Hot melt adhesive glue is a versatile bonding solution widely used in various industries because of its effectiveness and ease of application. This type of adhesive is applied using a hot melt adhesive gun, which melts the glue sticks and allows for quick and strong bonding of materials. Super strong adhesives like hot melt glue are ideal for tasks requiring durable connections, including fabric and cloth applications where fabric adhesive glue offers a reliable bond. The hot melt adhesive machine enhances the efficiency of adhesive application in industrial settings, ensuring precise and consistent results. Tapes and adhesives also complement hot melt glue by providing additional bonding options. Hot melt adhesive sticks, when heated in an adhesive glue gun, offer a fast-drying solution that is perfect for both professional and DIY projects. This versatility makes hot melt adhesives indispensable for tasks ranging from simple household repairs to complex manufacturing processes. Whether you need to attach fabric pieces, secure materials, or handle other bonding tasks, cloth adhesive glue delivers a strong, reliable bond across a variety of applications. For tasks involving various materials, choosing the right adhesive for material is essential. When working with plastic, strong adhesives for plastic materials ensure a durable bond, making them ideal for a wide range of industrial and DIY projects.

Choosing the Right Adhesive for Strong and Durable Bonding

Choosing the Right Adhesive for Strong and Durable Bonding

Selecting the right adhesive is crucial for ensuring durability, strength, and efficiency in various applications. Different types of adhesives are designed for specific materials and conditions, making it essential to choose the right one for optimal performance. A high-strength bonding adhesive is ideal for industrial uses, construction, and automotive applications, where durability under stress is necessary.

Different Types of Adhesives and Their Applications

1. Epoxy Adhesives

2. Cyanoacrylate (Super Glue)

3. Polyurethane Adhesives

4. Acrylic Adhesives

5. Hot Melt Adhesives (HMA)

6. Silicone Adhesives

7. Pressure-Sensitive Adhesives (PSA)

8. Contact Adhesives

How to Choose the Right Adhesive for Bonding

Adhesive Bonding for Different Surfaces

1. Metal Bonding

2. Wood Bonding

3. Plastic Bonding

4. Glass Bonding

5. Fabric & Leather Bonding

Blog Closure:

Additionally, investing in an adhesive dispenser machine or a glue machine streamlines the bonding process by ensuring precise and consistent adhesive application, reducing waste, and improving productivity. Whether for manual or automated setups, using the right adhesive with an efficient dispensing system guarantees long-term performance and stability, making your projects secure and successful.

FAQ

What is adhesive bonding?

Adhesive bonding is joining two surfaces using an adhesive substance.

What is the best adhesive for bonding metal to metal?

Epoxy adhesive is the best for bonding metal to metal.

What is bonding glue used for?

Bonding glue is used to join and secure various materials together.

What is bonding glue?

Bonding glue is a type of adhesive designed to create a strong bond between surfaces.

Which adhesive is best for joining plastic?

Cyanoacrylate (super glue) is best for joining plastic.

Which adhesive is best for granite?

Epoxy adhesive is best for granite.

How adhesive works?

Adhesive operates by facilitating a bond between surfaces, which can be accomplished through chemical reactions or by physically interlocking the surfaces together.

How adhesive is made?

Adhesive is made through chemical formulation processes that involve combining polymers and other materials to create a sticky substance.

Mahisa Packaging Systems LLP

Office Address :

Service & Spares :

Sales Inquiry :

Sales phone: +91 98210 49426

+91 84510 70625

+91 72089 76891

Sales email: sales@mahisa.com

Social Links :

Need Help? Chat with us