The Role of Hot Melt Adhesives in the Packaging Industry

The Role of Hot Melt Adhesives in the Packaging Industry

Hot melt adhesive for packaging has revolutionized the packaging industry with its efficiency and versatility. Utilizing a hot melt adhesive machine, this adhesive offers quick bonding properties, making it ideal for various packaging applications. Its uses span across different types of packaging, from corrugated boxes to cartons and even flexible packaging materials. One of the primary adhesive uses of hot melt adhesive in packaging is in carton sealing. The gluing process using hot melt adhesive is straightforward and efficient. The adhesive is heated to a molten state in the packaging glue machine and applied onto the desired surface. Upon cooling, it forms a strong bond, ensuring secure packaging. This process enhances packaging automation by facilitating faster production lines and reducing downtime. Hot melt adhesive glue is a go-to solution for companies seeking fast and reliable packaging. Moreover, adhesives for paper applications benefit from the unique properties of hot melt adhesive, ensuring that even paper packaging materials are sealed effectively. Additionally, hot melt adhesive dispensing systems play a crucial role in optimizing the application process, offering precise and consistent adhesive application, which contributes to increased efficiency.

Hot melt adhesive for packaging is a critical component in the modern packaging industry, offering reliable and efficient sealing solutions for a variety of applications. Hot melt adhesive application equipment plays a crucial role in applying adhesives with precision, ensuring consistent coverage for packaging materials. When it comes to food packaging applications, choosing the best hot melt adhesive is essential for ensuring product safety and maintaining packaging integrity. For carton sealing, industrial hot melt adhesive for carton sealing is widely used for its superior bonding strength and versatility, even in high-speed production environments. A key feature of hot melt adhesives is their fast bond strength, allowing for quick processing and packaging. This rapid bonding is especially critical for industries requiring fast-paced production lines. Some specialty high-temperature adhesives are formulated to withstand extreme conditions, making them ideal for products exposed to high heat during storage or transport. Applied adhesives offer superior adhesion to a range of materials, including cardboard, plastic, and metal, ensuring that packaging stays intact during transit. For businesses requiring tailored solutions, custom hot melt adhesive for plastic packaging provides the flexibility needed for unique packaging requirements. Hot melt adhesive glue offers an environmentally friendly option, with reduced solvent emissions, making it an excellent choice for companies seeking sustainable packaging solutions.

Hot melt adhesive glue has emerged as a game-changer in the packaging industry, particularly in the realm of hot melt adhesive for packaging applications. As the demand for efficient and reliable packaging solutions continues to surge, the packaging adhesives market witnesses a parallel rise in the prominence of hot melt adhesive products. When considering hot melt adhesive for packaging, understanding the important characteristics of adhesive is crucial for effective application and optimal results. One of the most important characteristics of hot melt adhesive is its rapid setting time. This feature streamlines the packaging process, allowing for quicker turnaround times and increased productivity. Hot melt adhesive dispensing systems play a pivotal role in the efficient application of adhesive glue in packaging operations. In the context of packaging solutions, hot melt adhesive enables the automation of packaging processes, reducing the reliance on manual packaging methods. Furthermore, hot melt adhesive distributors ensure that businesses have access to a wide variety of high-quality hot melt adhesive products, helping to meet specific packaging needs. Additionally, automatic hot melt adhesive applicators enhance the precision and speed of adhesive application, further improving packaging efficiency. For applications requiring enhanced durability, water-resistant hot melt adhesive for packaging applications offers an excellent solution, ensuring that the packaging remains secure even in challenging environments.

Packaging adhesives are integral components in the production of various packaging materials, offering versatility and reliability in bonding applications. Among the types of adhesives used in packaging, hot melt adhesives stand out for their efficiency and effectiveness. Classification of adhesive types encompasses various categories based on their chemical composition, curing mechanisms, and application methods. This characteristic makes them ideal for automatic packaging processes, where speed and efficiency are paramount. One common application of hot melt adhesives is in the production of corrugated packaging boxes. Hot melt adhesive equipment, including dispensing systems and applicators, play a crucial role in the seamless integration of adhesives into packaging processes. With a robust presence of hot melt adhesive manufacturers in India, the market is characterized by a diverse array of adhesive options catering to various packaging needs. In tandem with the advancements in adhesive manufacturing, the development of packaging machines has also been instrumental in enhancing packaging efficiency and productivity. For applications in extreme conditions, durable hot melt glue for packaging in extreme temperatures provides an effective solution, ensuring strong and lasting bonds even under challenging circumstances.

Its uses are manifold, ranging from sealing corrugated packaging boxes to bonding laminates and substrates in the packaging industry. To facilitate efficient application, hot melt adhesive is often applied using specialized equipment such as hot melt adhesive coating machines and hot melt glue dispensers. Adhesive dispensing machines further streamline the packaging process by automating adhesive application, reducing manual labor and increasing production efficiency. Overall, hot melt adhesive for packaging offers a versatile and effective solution for a wide range of packaging needs. Among its various applications, one notable use is its efficacy as a waterproof hot glue adhesive.

Among these, hot melt adhesive stands out as a versatile and efficient solution for bonding a wide range of packaging materials. Hot melt adhesive for packaging is particularly prized for its quick setting time, strong bonding properties, and versatility across different substrates. Hot melt adhesive manufacturers produce a diverse array of hot melt adhesive products tailored to specific packaging needs. These adhesives are available in various forms, including hot melt adhesive sticks, pellets, and cartridges, facilitating easy integration into hot melt packaging systems. Among the most common types of adhesives used in packaging are hot melt adhesives. These systems utilize hot melt adhesive dispensers and applicators to precisely apply adhesive to packaging materials such as cardboard packaging boxes, ensuring secure seals and optimal packaging integrity. With the support of advanced adhesive packaging systems and a diverse range of hot melt adhesive formulations, manufacturers can meet the evolving demands of the packaging industry while ensuring optimal performance and customer satisfaction. For heavy-duty applications, high tack hot melt adhesive for heavy-duty packaging offers superior bonding strength, making it ideal for demanding packaging tasks.

The Role of Hot Melt Adhesives in the Packaging Industry

The Role of Hot Melt Adhesives in the Packaging Industry

History of Hot Melt Adhesives in India

Timeline of Hot Melt Adhesives in India

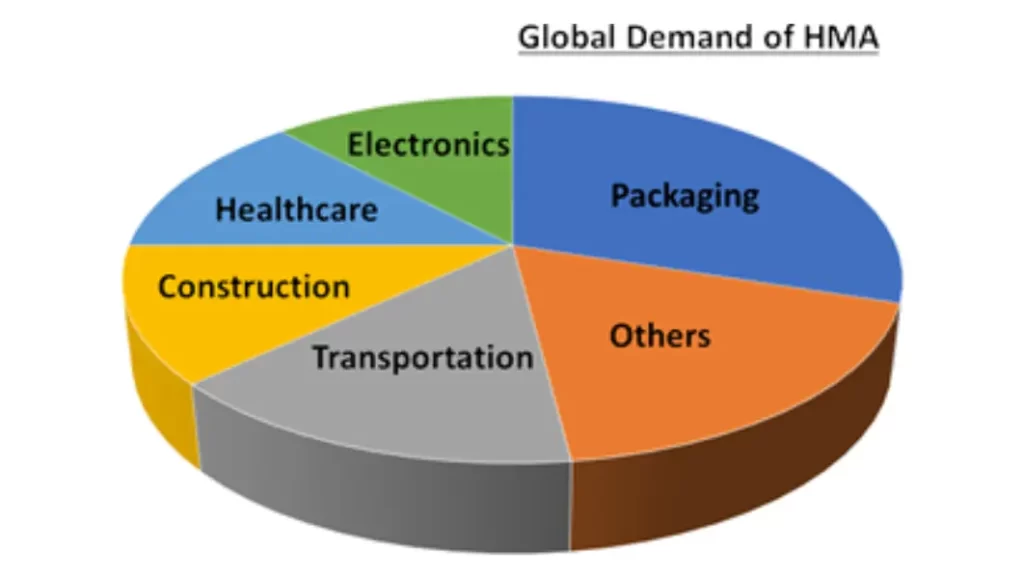

Market Industry for Hot Melt Adhesives in Packaging

Key Aspects of the Market Industry:

Benefits of Hot Melt Adhesives in Packaging

Conclusion

Mahisa Packaging Systems LLP

Office Address :

Service & Spares :

Sales Inquiry :

Sales phone: +91 98210 49426

+91 84510 70625

+91 72089 76891

Sales email: sales@mahisa.com

Social Links :

Need Help? Chat with us