Hot melt glue equipment plays a crucial role in various industries by ensuring a fast, reliable, and efficient gluing process. Whether in packaging, woodworking, automotive, or textiles, these systems provide precision in glue dispensing, reducing waste and improving production speed.

The right equipment enhances glue bonding, ensuring strong adhesion to different materials, from plastics to metals and fabrics. Understanding glue properties, such as viscosity, open time, and setting speed, is key to selecting the right solution for specific applications. Advanced hot melt glue systems offer automated control, consistent application, and minimal downtime, making them an essential asset for manufacturers.

With growing demand for sustainable and high-performance adhesives, hot melt glue equipment continues to evolve, offering innovative solutions for modern production needs.

Selecting the right types of glue for hot melt glue equipment is essential to achieving optimal glue quality and glue strength in various applications. Several formulations are available, each designed for specific industries and materials.

1. EVA (Ethylene Vinyl Acetate) Glue –

A versatile choice for packaging, woodworking, and textiles, offering strong adhesion and quick setting.

2. Polyolefin Glue –

Known for superior glue strength, ideal for bonding difficult surfaces like plastics and metals.

3. Polyurethane (PUR) Glue –

Provides flexible yet durable bonding with excellent heat and moisture resistance.

4. Metallocene Glue –

Enhances glue application efficiency with lower char buildup, improving the performance of gluing machines.

5. Pressure-Sensitive Adhesives (PSA) –

Used for labels, tapes, and self-adhesive products, applied using specialized glue applicators.

Choosing the right hot melt glue ensures efficiency, durability, and strong bonding for industrial applications.

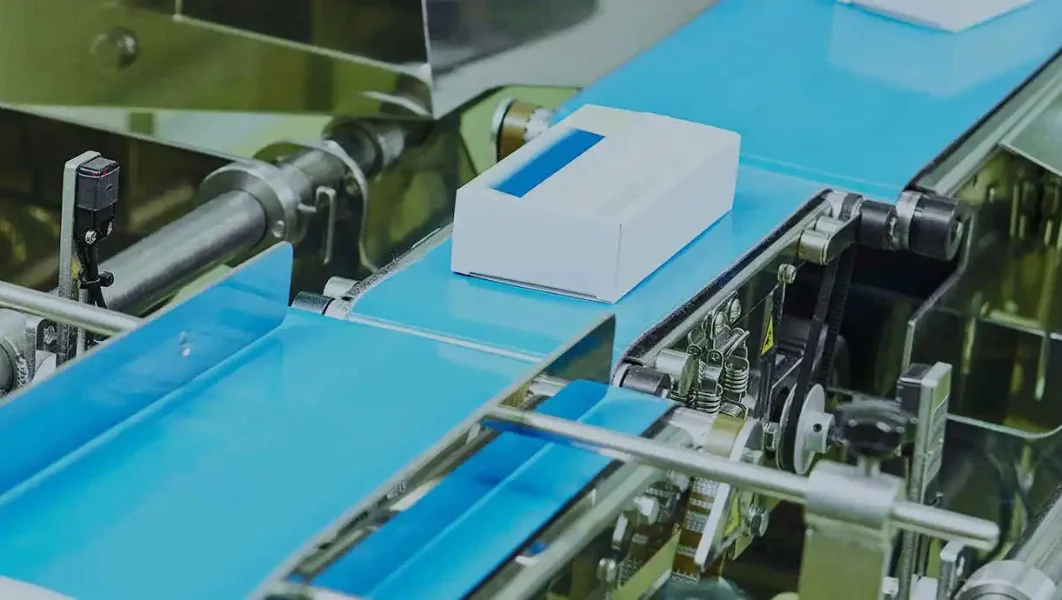

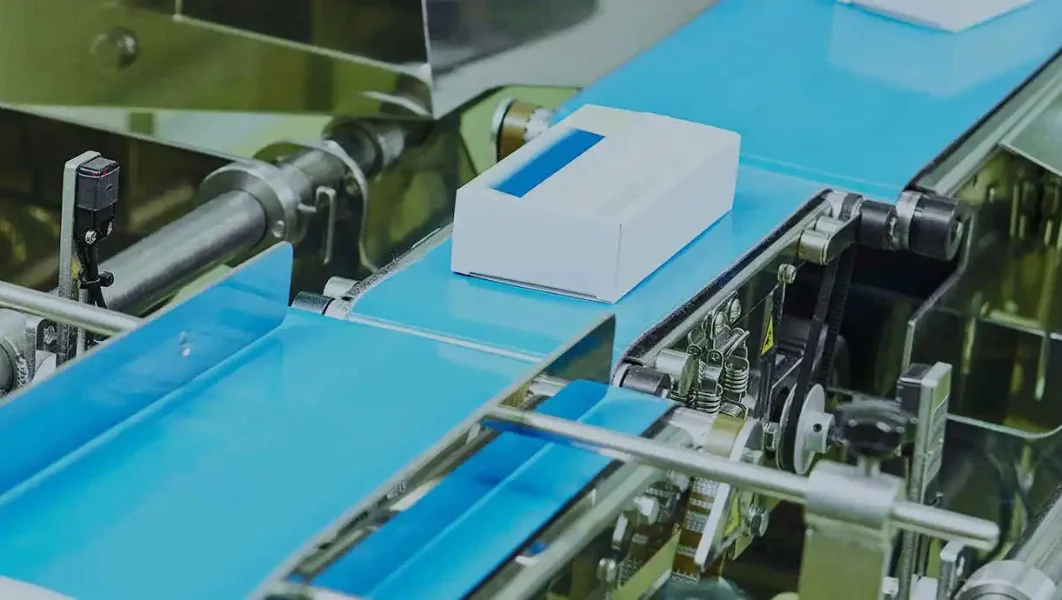

Hot melt glue equipment plays a vital role in the packaging industry, ensuring secure seals, efficient production, and cost savings. The type of gluing machines and glue application methods vary based on company size and production scale.

1. Small-Scale Businesses & Startups –

Small businesses, such as local bakeries or handmade product brands, require compact Hot melt glue equipment like handheld hot melt guns or small manual glue dispenser machine. These solutions provide flexibility and affordability while maintaining glue quality for cartons, labels, and customized packaging.

2. Medium-Sized Manufacturers –

Mid-sized companies need semi-automated gluing machines to improve efficiency while keeping costs under control. Tabletop or conveyor-based systems enhance glue strength and consistency for e-commerce, food packaging, and consumer goods, ensuring faster operations.

3. Large-Scale Packaging Facilities –

High-volume manufacturers, such as FMCG and logistics companies, rely on fully automated hot melt glue dispensing systems. These advanced machines offer precision, high-speed glue application, and reduced waste, optimizing mass production without compromising glue quality.

Hot melt glue equipment is essential for industries requiring efficient and strong glue bonding. Businesses can choose between manual glue dispensers and automated glue dispensers based on production scale, precision, and workflow requirements.

a. Handheld or foot-operated for controlled glue dispensing

b. Lightweight and easy to use

c. Requires manual loading and application

a. Cost-effective solution for low-volume production

b. Ideal for customized or irregular-shaped products

c. Portable and flexible for various applications

c. Woodworking & furniture repair

d. Automotive & electronics (for small repairs)

a. Best for low-volume production

b. Typically applies 1-2 kg of glue per hour

a. EVA-based hot melt glue

b. Pressure-sensitive adhesives (PSA)

c. Low-viscosity glues for flexible applications

a. Small boxes and cartons

c. Wood and fabric bonding

a. Temperature control for different glue properties

b. Nozzle variety for different glue application needs

c. Compatible with different glue stick sizes

a. Fully automated gluing machines with conveyor integration

b. Programmable settings for precise glue bonding

c. Can be integrated into assembly lines for high-speed production

a. High efficiency and minimal waste

b. Consistent glue strength for large-scale applications

c. Reduces labor costs and human errors

a. Packaging (FMCG, e-commerce, logistics)

b. Automotive and electronics

c. Furniture and woodworking

a. High-speed glue application, handling 10-50 kg of glue per hour

b. Suitable for continuous operations in large factories

a. Polyurethane (PUR) for high-strength bonding

b. Metallocene glue for clean application

c. Specialty adhesives for temperature-sensitive packaging

a. Corrugated boxes and cartons

b. Sealed food and beverage packaging

c. High-strength bonded furniture and upholstery

d. Sealed automotive and electronic components

a. Automated temperature and pressure control

b. Multiple nozzle configurations for different materials

c. Smart monitoring for real-time adjustments

For small businesses or irregular applications, manual glue dispensers offer flexibility and affordability. In contrast, automated glue dispensers enhance speed, precision, and efficiency in large-scale production. Selecting the right equipment ensures glue quality, cost-effectiveness, and optimized production output.

Proper maintenance of hot melt glue equipment ensures consistent glue quality, extends machine lifespan, and prevents costly downtime. Regular cleaning and care help maintain efficient glue dispensing and strong glue bonding in various applications. Here are essential maintenance and care tips:

a. Clean the glue applicator and nozzles after each use to prevent blockages.

b. Use manufacturer-recommended cleaning agents to remove hardened glue residue.

c. Avoid overheating the glue tank, which can cause carbonization and clogging.

a. Inspect nozzles for wear and replace them if glue application becomes inconsistent.

b. Use the correct nozzle size to ensure proper glue strength and flow control.

a. Maintain optimal temperature settings to avoid overheating or under-melting glue.

b. Different types of glue require specific temperature ranges for proper bonding.

b. Ensure all seals are intact to prevent air bubbles or contamination in the glue system.

a. Follow a routine maintenance schedule based on usage intensity.

c. Perform periodic deep cleaning of tanks and feeding systems.

a. Low-quality adhesives can cause buildup and reduce machine efficiency.

b. Select the right types of glue compatible with your equipment for better glue bonding.

a. Ensure staff is trained in safe and efficient glue application techniques.

By following these maintenance tips, businesses can maximize productivity, maintain glue quality, and prolong the lifespan of their hot melt glue equipment.

Hot melt glue equipment is a game-changer for industries that rely on efficient glue bonding and high-quality glue application. Whether using manual glue dispensers for flexibility or automated gluing machines for large-scale production, selecting the right system enhances productivity, reduces waste, and ensures durable adhesion.

As demand for faster and more sustainable packaging solutions grows, investing in advanced hot melt glue dispensing technology will keep businesses competitive. By following best practices in usage and maintenance, manufacturers can achieve seamless, reliable, and cost-effective glue application in their production lines.