• Substrate Material:

The materials being bonded play a crucial role. Hot melt glue adheres best to porous surfaces like wood, paper, and fabric, as the molten glue can penetrate the material and create a mechanical bond in addition to the adhesive bond. Smooth, non-porous surfaces like glass or metal require formulations specifically designed for these materials, often involving surface preparation techniques to improve adhesion.

• Open Time:

Open time refers to the amount of time available to join the materials after the glue is applied. Hot melt glue has a relatively short open time, typically ranging from a few seconds to a minute or two. If the materials are not joined within the open time, the glue will begin to solidify, and the bond strength will be compromised.

• Cure Time:

While hot melt glue sets quickly, it continues to gain strength as it cools and fully solidifies. Allowing sufficient cure time before stressing the bond is crucial for achieving maximum glue strength.

• Temperature:

Hot melt glue is thermoplastic, meaning it softens when heated and hardens when cooled. High temperatures can weaken or even melt the glue, while very low temperatures can make it brittle and prone to cracking. Therefore, the temperature range the bonded joint will be exposed to in its end-use environment is a crucial consideration.

• Environmental Factors:

Exposure to moisture, UV light, and certain chemicals can degrade the glue over time, reducing its strength. For outdoor applications or those involving harsh environments, specialized formulations with enhanced resistance to these factors are necessary.

The glue strength of an adhesive is often quantified using several metrics:

• Peel Strength:

This measures the force required to peel one material away from another. It’s particularly relevant for applications where the bond is subjected to peeling forces, such as attaching labels or edge banding.

• Tensile Strength:

This measures the force required to pull the bonded materials apart in a straight line. It’s important for applications where the bond is subjected to tension, such as structural bonding.

• Shear Strength:

This measures the force required to slide the bonded materials past each other. It’s relevant for applications where the bond is subjected to shear forces, such as joining overlapping materials.

The specific strength values for hot melt glue vary widely depending on the formulation and the factors mentioned above. Generally, hot melt glue exhibits moderate peel and tensile strength and good shear strength. Manufacturers’ data sheets provide specific strength values for their products, which should be consulted when selecting a glue for a particular hot melt glue application.

Hot melt glue is a versatile adhesive used in a wide range of hot melt glue uses:

• Woodworking:

Edge banding, assembling furniture components, and attaching decorative elements are common woodworking applications. Specialized formulations offer excellent adhesion to wood and provide sufficient strength for many woodworking projects.

• Crafts and DIY:

Hot melt glue is a staple in crafting and DIY projects due to its ease of use and versatility. It can be used to attach a wide variety of materials, including paper, fabric, plastic, and wood.

• Automotive:

Interior trim attachment, wire harnessing, and sound dampening are some automotive applications. Specialized formulations are designed to withstand the extreme temperatures and vibrations found in automotive environments.

• Textiles:

Bonding fabrics, attaching embellishments, and hemming are common textile applications. Flexible formulations are available that maintain their bond even when the fabric is flexed or washed.

• Electronics:

Securing components, insulating wires, and providing strain relief are some electronics applications. Electrically insulating formulations are available to prevent short circuits.

Despite its versatility, hot melt glue has limitations:

• Lower Strength Compared to Structural Adhesives:

Compared to epoxies, cyanoacrylates (super glues), and other structural adhesives, hot melt glue generally has lower strength. It’s not suitable for applications requiring extremely high bond strength or load-bearing capabilities.

• Temperature Sensitivity:

As a thermoplastic, hot melt glue is sensitive to temperature extremes. High temperatures can weaken or melt the glue, while low temperatures can make it brittle.

• Limited Chemical Resistance:

Hot melt glue is generally not resistant to solvents, oils, and other chemicals. Exposure to these substances can degrade the glue and weaken the bond.

• Not Ideal for Outdoor Use:

Unless specifically formulated for outdoor use, hot melt glue can degrade when exposed to moisture, UV light, and temperature fluctuations.

• Short Open Time:

The short open time of hot melt glue can be a limitation in some applications, requiring quick and precise assembly.

Let’s briefly compare hot melt glue to other common adhesives:

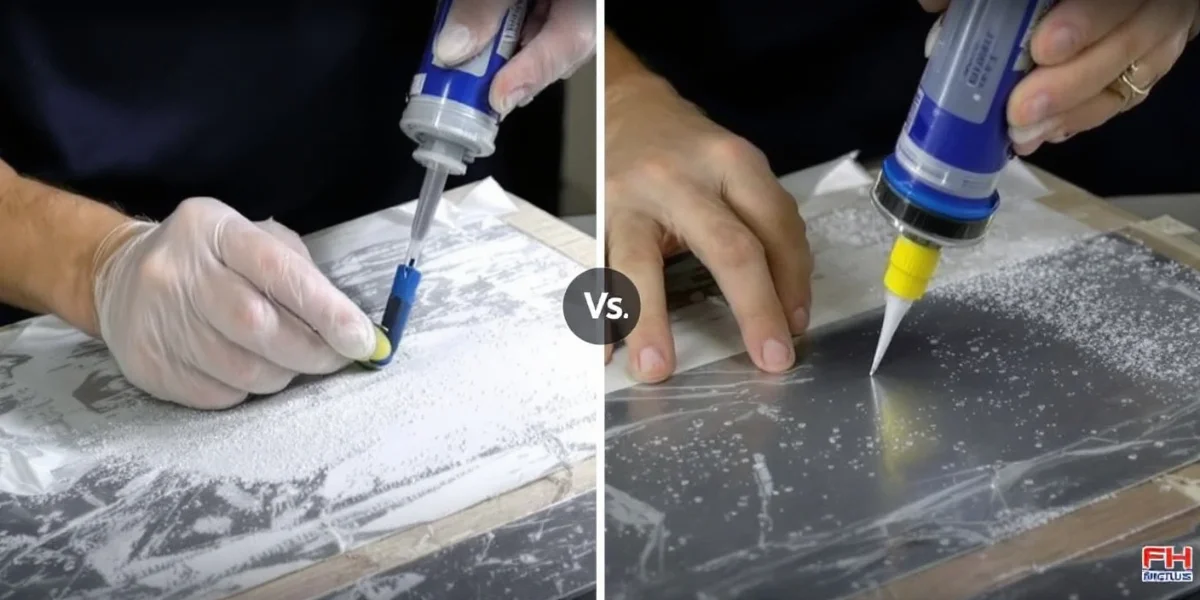

• Epoxy:

Offers superior strength, chemical resistance, and temperature resistance compared to hot melt glue. However, it typically requires mixing, has a longer cure time, and can be more difficult to apply.

• Cyanoacrylate (Super Glue):

Provides very fast bonding and high tensile strength, but is brittle and has poor impact resistance. It’s also less versatile than hot melt glue and can be difficult to apply precisely.

• Polyurethane Glue:

Offers excellent adhesion to a wide variety of materials, including wood, plastic, and metal. It’s also water-resistant and flexible, but has a longer cure time than hot melt glue.

• White Glue (PVA):

A general-purpose adhesive commonly used for paper, wood, and fabric. It’s non-toxic and easy to use but has lower strength and water resistance than hot melt glue.

Selecting the right hot melt glue for a specific hot melt glue application involves considering several factors:

• Materials Being Bonded:

Choose a formulation specifically designed for the materials you are bonding.

• Strength Requirements:

Determine the required glue strength based on the expected loads and stresses.

• Temperature and Environmental Conditions:

Consider the temperature range and environmental conditions the bonded joint will be exposed to.

• Application Method:

Choose a hot melt glue equipment appropriate for the scale and complexity of the application.

• Open Time and Cure Time:

Select a glue with an open time and cure time that fits your assembly process.

To summarize, the advantages of hot melt glue include:

• Fast set time, increasing productivity

• Ease of hot melt glue application

• Versatility in bonding various materials