In the world of modern manufacturing, the demand for fast, reliable, and versatile bonding solutions has never been higher. Enter pressure sensitive hot melt adhesive (HMPSA) a powerhouse in the adhesive industry that combines the instant grab of a sticker with the industrial strength of hot melt technology.

Whether you are in packaging, automotive assembly, or medical device manufacturing, understanding the nuances of Adhesive Formulation and application is key to product success.

A pressure sensitive hot melt adhesive is a type of thermoplastic bonding agent that remains “tackified” (sticky) even after cooling. Unlike traditional hot melts that set into a hard solid, HMPSAs maintain a permanent grip and require only light pressure to create a bond between two surfaces.

To understand the value of a Hot Melt Pressure Sensitive Adhesive, it is helpful to compare it to other common bonding agents:

The performance of any pressure sensitive adhesive depends entirely on its chemical makeup. PSA Chemicals are typically blended to balance three critical properties: Tack, Cohesion, and Adhesion.

The science of formulating PSA Chemicals involves manipulating the molecular structure to hit a specific target for these three properties:

1. Tack (The “Quick Grab”):

This is the ability of the adhesive to form a bond with a surface almost instantaneously under light pressure. High tack is essential for high-speed labeling.

2. Adhesion (The “Peel Strength”):

This measures the bond strength between the adhesive and the substrate. It is determined by the molecular attraction (Van der Waals forces) between the pressure sensitive adhesive and the surface it is touching.

3. Cohesion (Internal Strength):

This is how well the adhesive sticks to itself. High cohesion prevents the adhesive from splitting down the middle or leaving a sticky residue when removed.

A standard Hot Melt Pressure Sensitive Adhesive is not a single substance but a complex blend of polymers and additives.

1. Hard Segments (Styrene):

These provide Adhesive Strength and heat resistance.

2. Soft Segments (Rubber/Butadiene):

These provide flexibility and the ability to “flow” onto a surface.

Raw polymers aren’t actually very sticky. Formulators add tackifiers often derived from tree rosin or petroleum to give the adhesive its “bite.” By adjusting the ratio of tackifier to polymer, chemists can make the adhesive either “permanent” or “removable.”

These are typically oils that lower the viscosity of the melt. They make the adhesive easier to apply at lower temperatures and improve the “wet-out” (how well the glue spreads across the surface at a microscopic level).

If the formulation is too viscous, the bond will “creep” or slide over time. If it is too elastic, it won’t “wet” the surface properly, leading to a weak bond that pops off easily.

1. Polymers:

Usually Styrenic Block Copolymers (SBC), these provide the structural integrity and Adhesive Strength.

2. Tackifiers:

Resins added to create that “instant grab” feeling.

3. Plasticizers:

Oils used to control the viscosity and flexibility of the adhesive.

4. Antioxidants:

Added to prevent the material from breaking down during the high-heat application process.

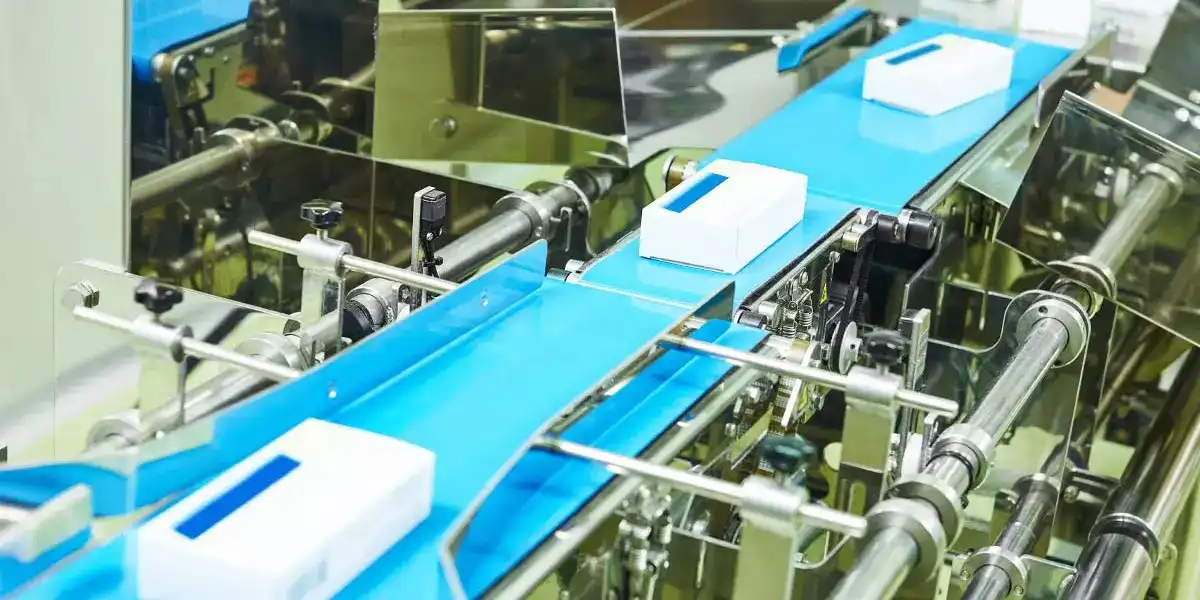

Because they don’t require drying time, HMPSAs are the “go-to” for high-speed production lines.

From Amazon shipping labels to craft beer bottles, HMPSAs ensure that labels stick instantly and stay put, even on curved or uneven surfaces.

HMPSAs are used to bond foam, fabric, and dashboard components. They are preferred because they add minimal weight and emit zero Volatile Organic Compounds (VOCs), keeping the “new car smell” safe.

1. Increased Production Speed:

Since there is no water or solvent to evaporate, parts can be moved to the next stage of production immediately.

2. Reduced Footprint:

You don’t need long drying tunnels or ovens, saving floor space and energy costs.

3. Long Shelf Life:

These adhesives are highly stable and can be stored for long periods without losing their bonding properties.

4. Versatility:

They bond well to “low energy” surfaces like plastics (polypropylene and polyethylene) where other glues might fail.

When choosing a pressure sensitive hot melt adhesive, you must consider the environment where the product will live. Adhesive Strength is influenced by:

1. Temperature:

Will the bond be exposed to extreme cold (freezers) or high heat (automotive engines)?

2. Surface Energy:

Is the substrate “easy” to bond to (like cardboard) or “difficult” (like Teflon or oily plastics)?

3. Shear Stress:

Will the bond be pulled apart sideways over a long period?

The chemistry of your adhesive determines its success. For example, a formulation designed for a removable “Post-it” style note uses very different PSA Chemicals than a permanent industrial shipping label.

Modern Adhesive Formulation is moving toward bio-based polymers and biodegradable resins to meet the growing demand for sustainable packaging solutions.

Generally, yes. Because HMPSAs are rubber or acrylic-based and contain no water, they are naturally resistant to moisture.

While they remain tacky, most industrial HMPSAs are designed for a single permanent bond. However, specific “repositionable” formulations exist for consumer products.

Most Hot Melt Pressure Sensitive Adhesives are applied between 150°C and 180°C (300°F – 350°F).

As industries push for faster, greener, and stronger assembly methods, pressure sensitive hot melt adhesive technology continues to evolve. By mastering Adhesive Formulation and selecting the right PSA Chemicals, manufacturers can reduce waste and improve product durability.

Whether you’re looking for extreme Adhesive Strength or a clean, removable bond, the versatility of HMPSAs makes them an essential tool in the modern industrial toolkit.