EcoPlus

Simple. Economical.

Manual hot-melt adhesive dispensing.

750-800 units processed per hour.

Advantages of Mahisa equipment

Savings with Mahisa equipment

Environmental advantages

Improved packaging standards

Installations

Customers

Countries

Years of experience

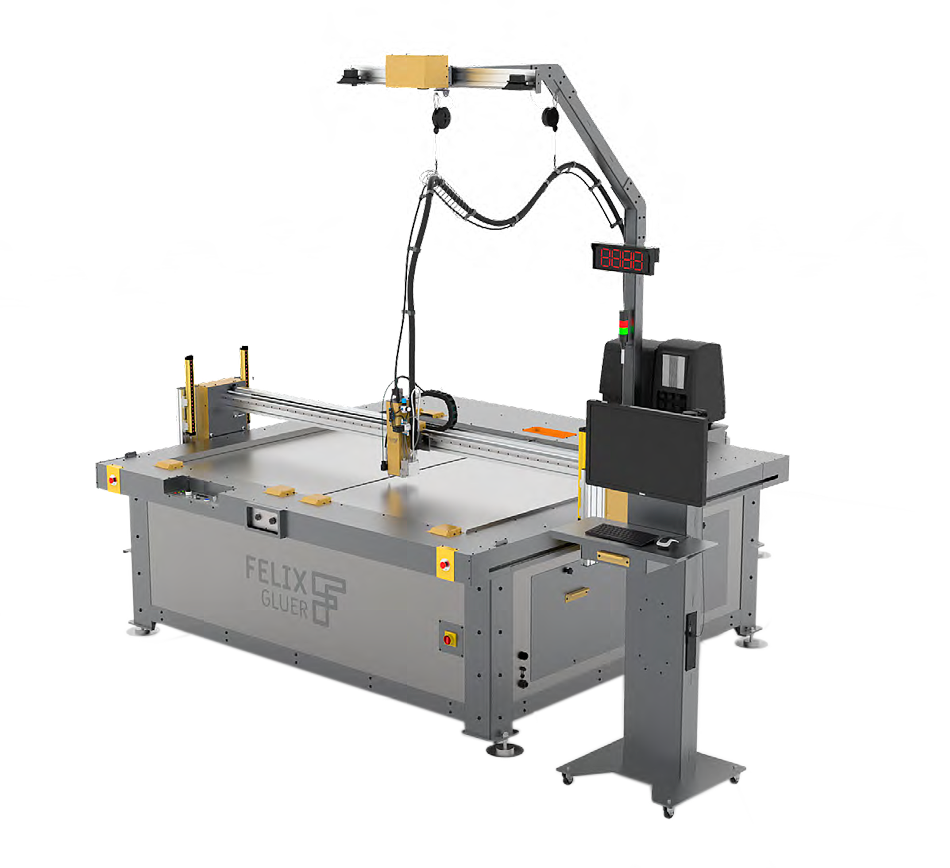

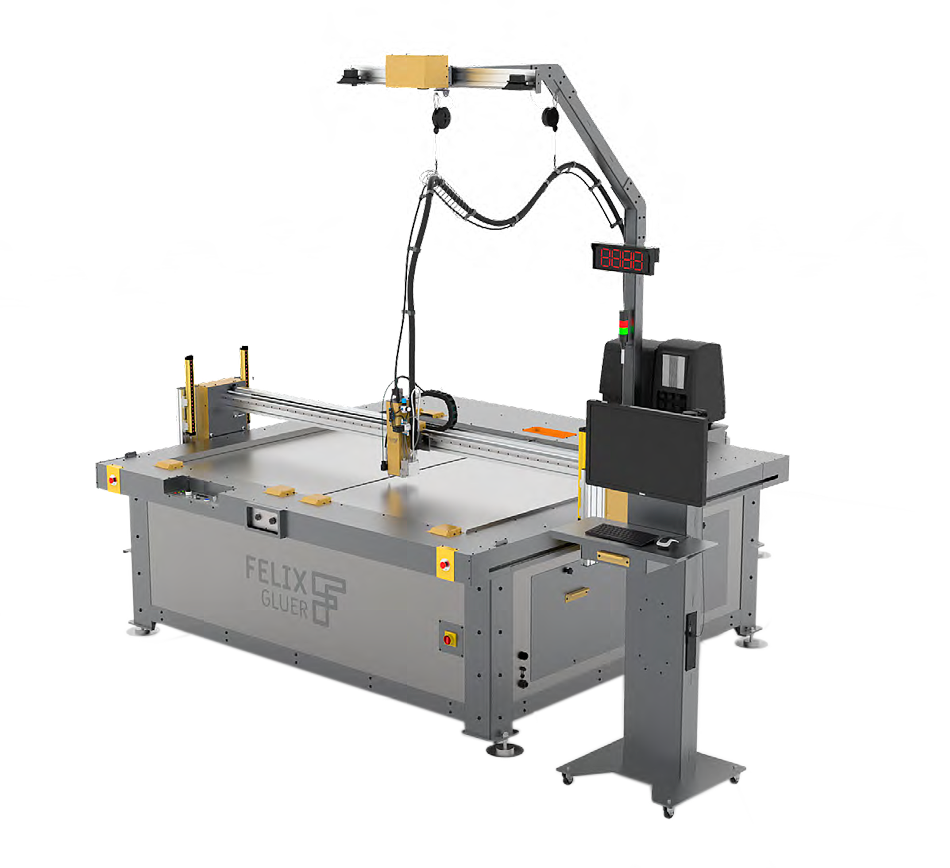

SmartPlot

EcoPlus

Simple. Economical.

Manual hot-melt adhesive dispensing.

750-800 units processed per hour.

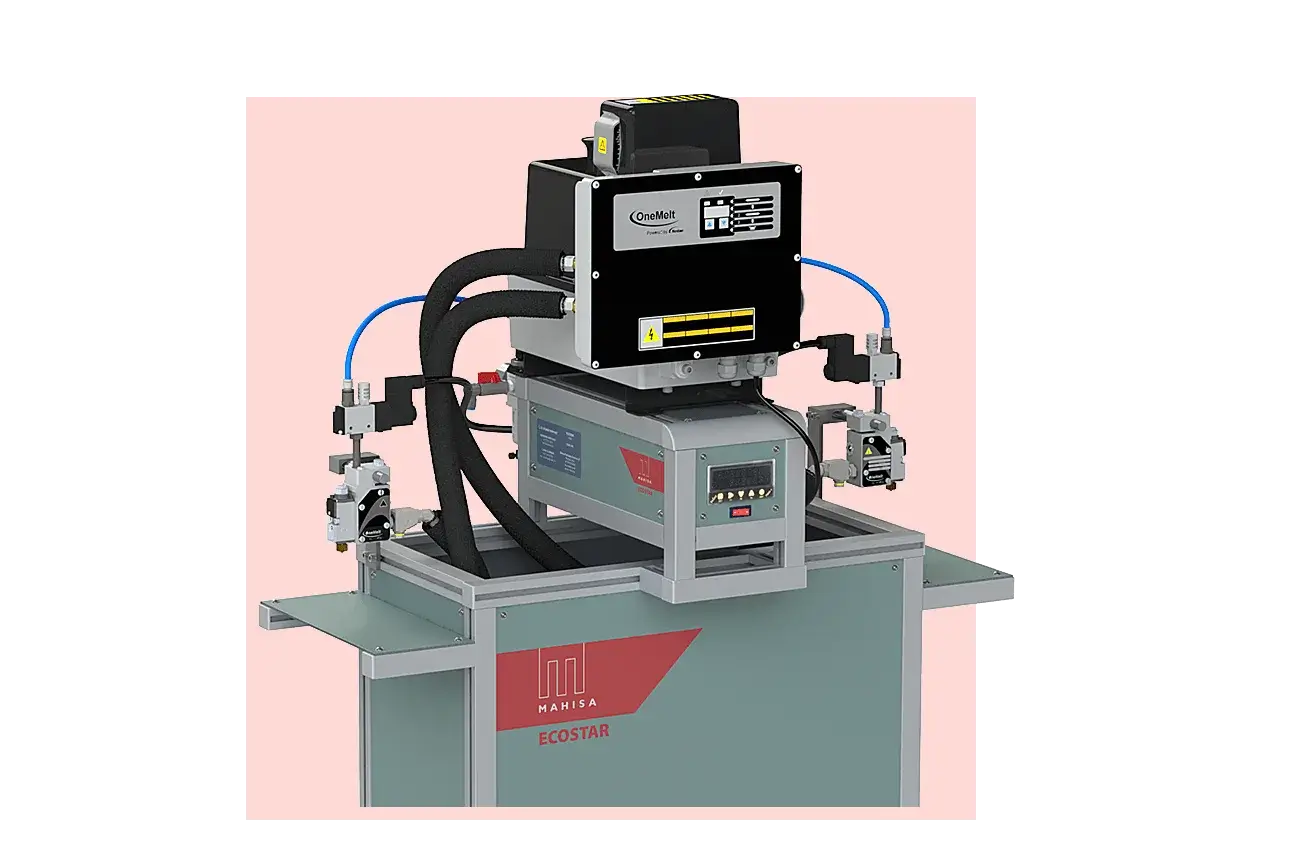

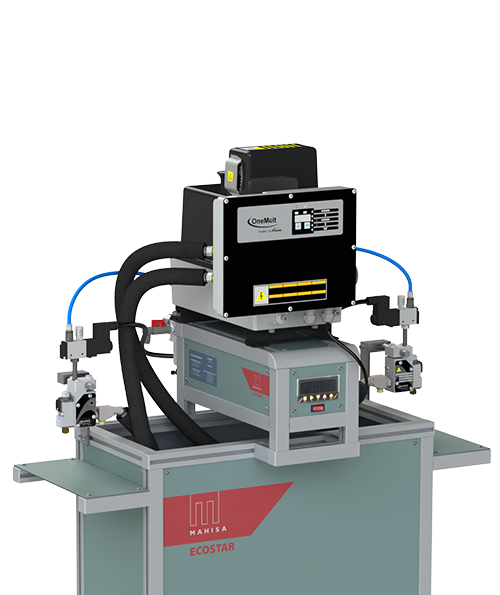

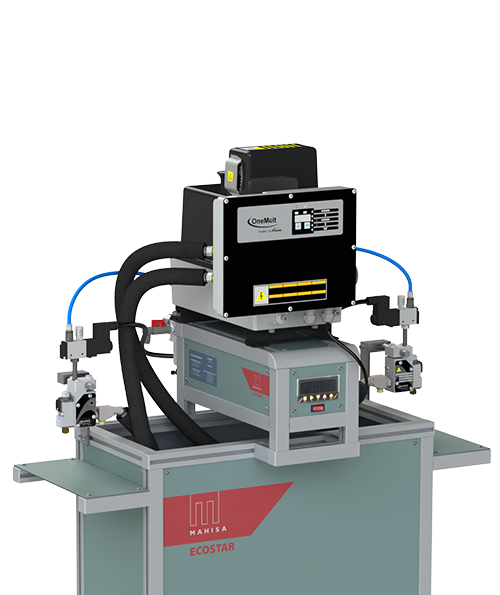

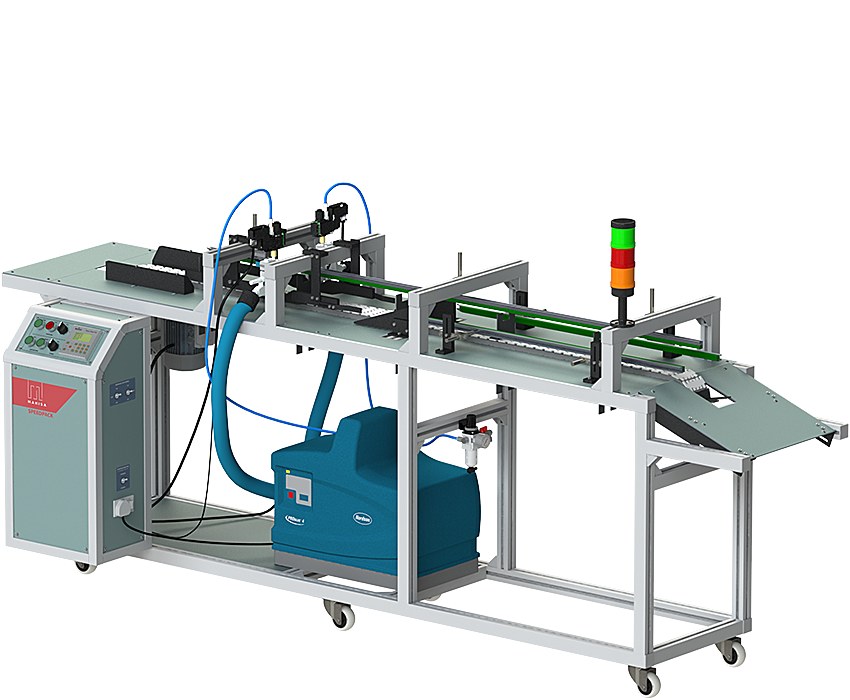

EcoStar

Low volume. High quality.

Manual hot-melt adhesive dispensing

Nordson melters with Mahisa controls.

750-800 units processed per hour.

Manual hot-melt adhesive dispensing

Nordson melters with Mahisa controls.

750-800 units processed per hour.

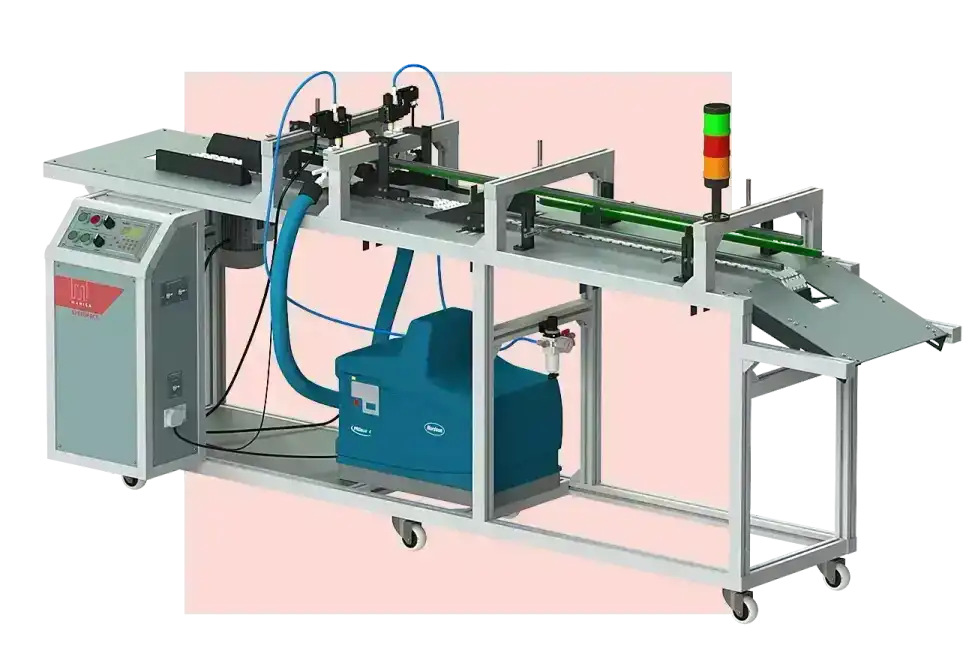

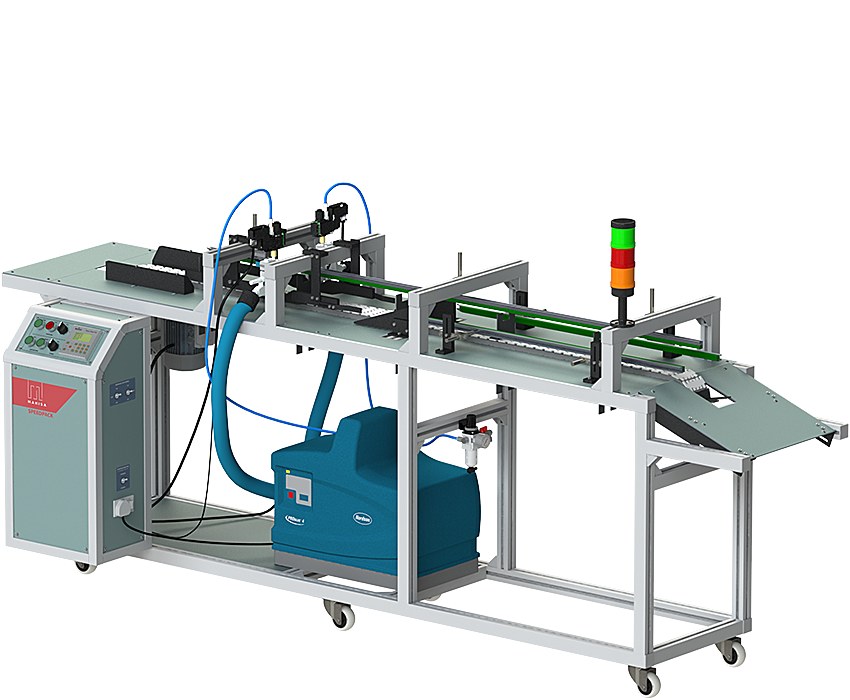

Compact size. High speed.

Semi-automatic continuous 2-flap gluer & folder

60 cartons per minute.

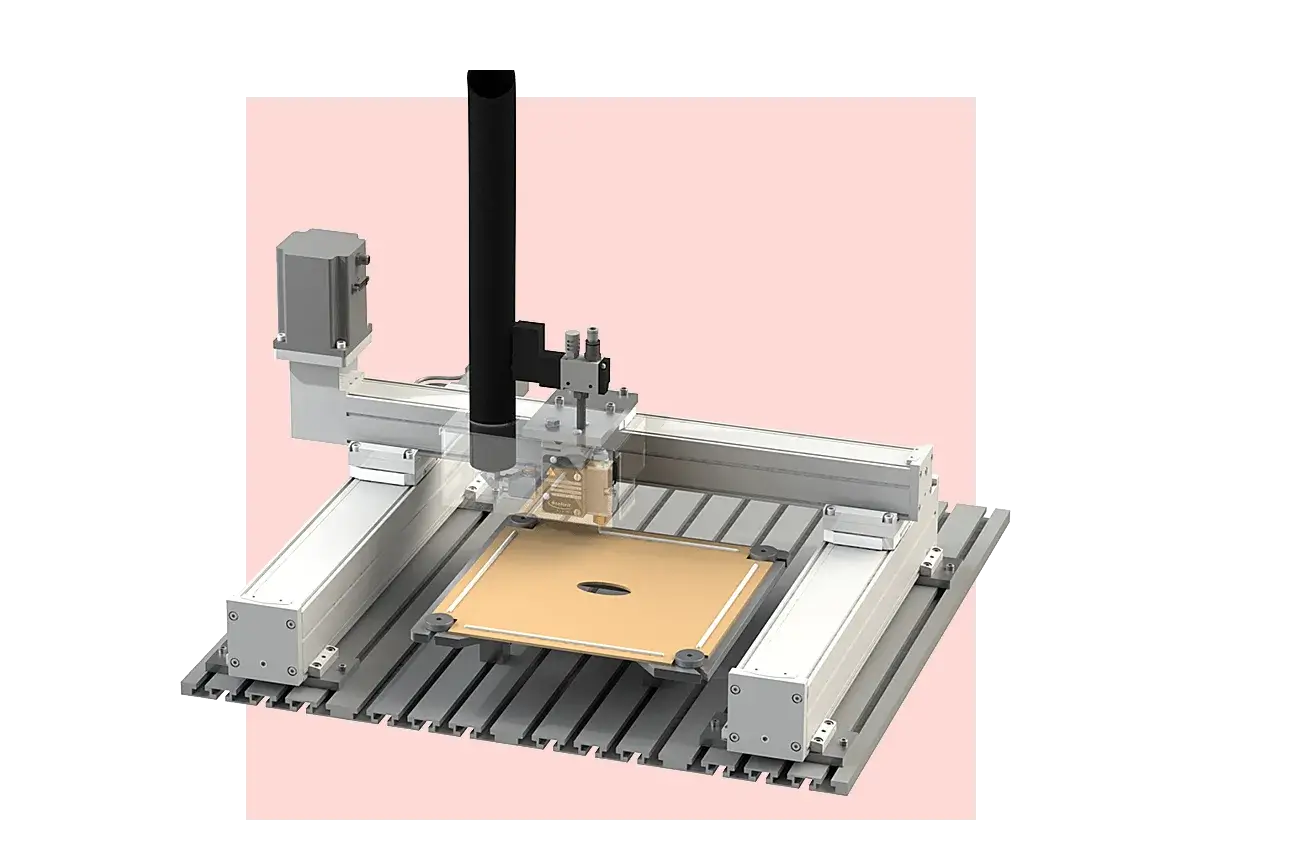

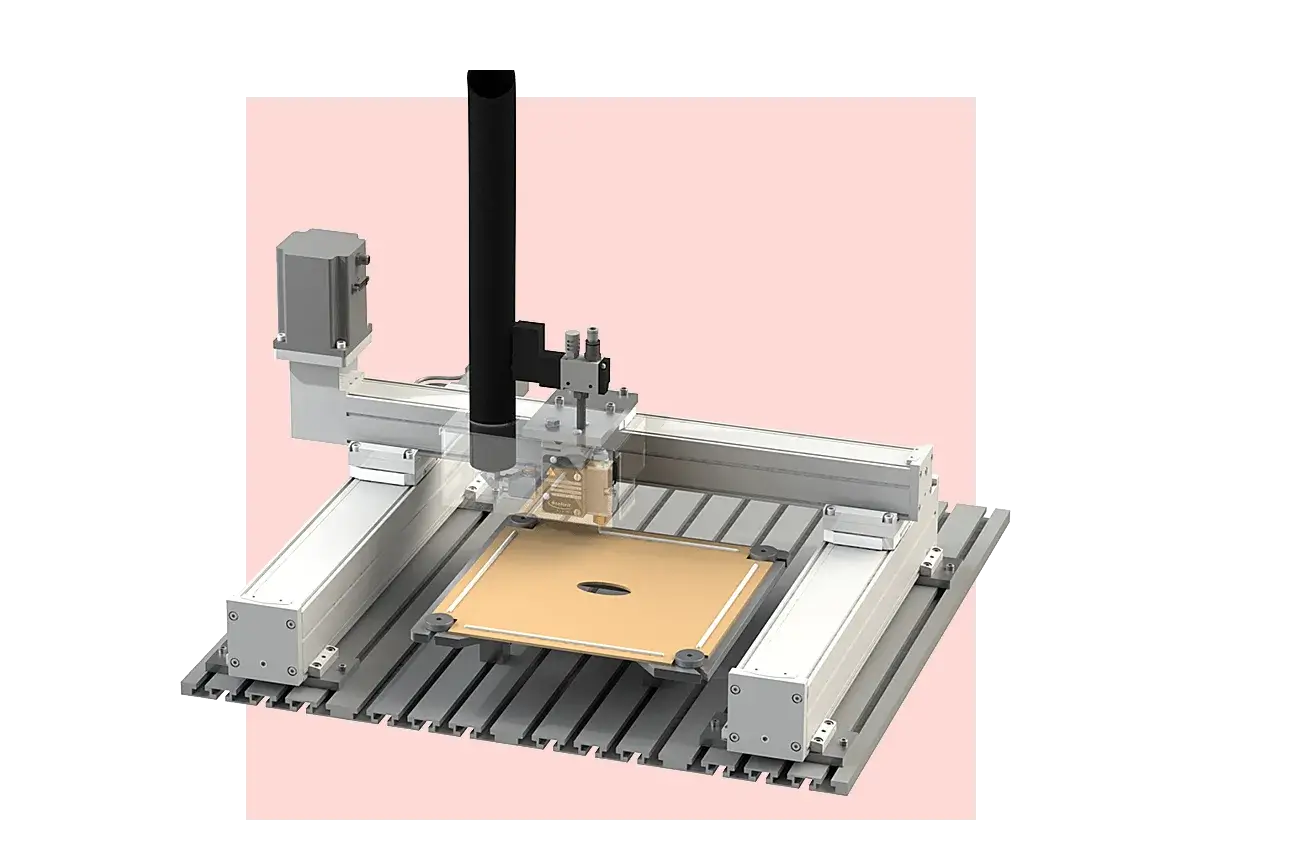

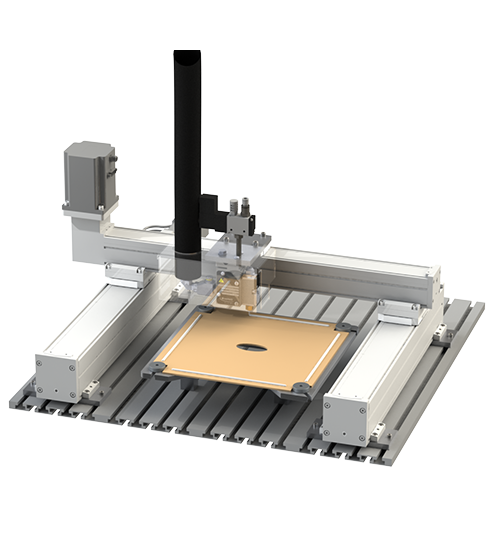

For the smarter you.

State-of-the-art XY glue plotter

CNC controlled hot-melt and cold-glue dispensing on flat parts.

What People Say

Blogs You May Like..

Mahisa Packaging Systems LLP

Office Address :

Service & Spares :

Sales Inquiry :

Sales phone: +91 98210 49426

+91 84510 70625

+91 72089 76891

Sales email: sales@mahisa.com

Social Links :

Need Help? Chat with us