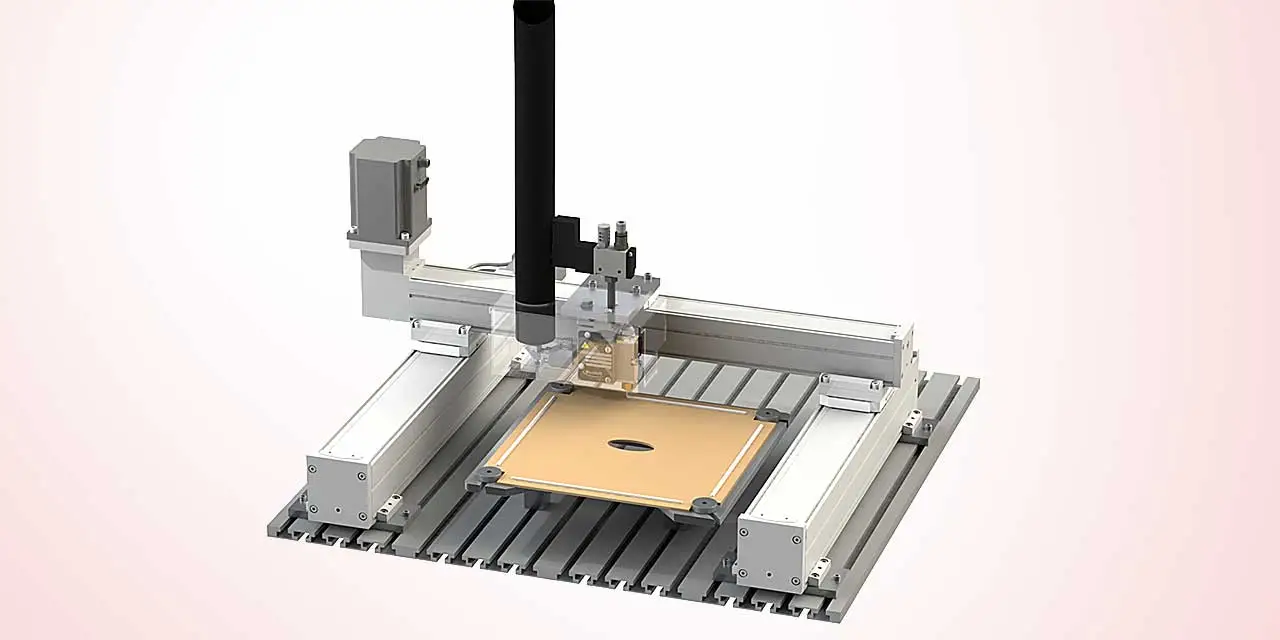

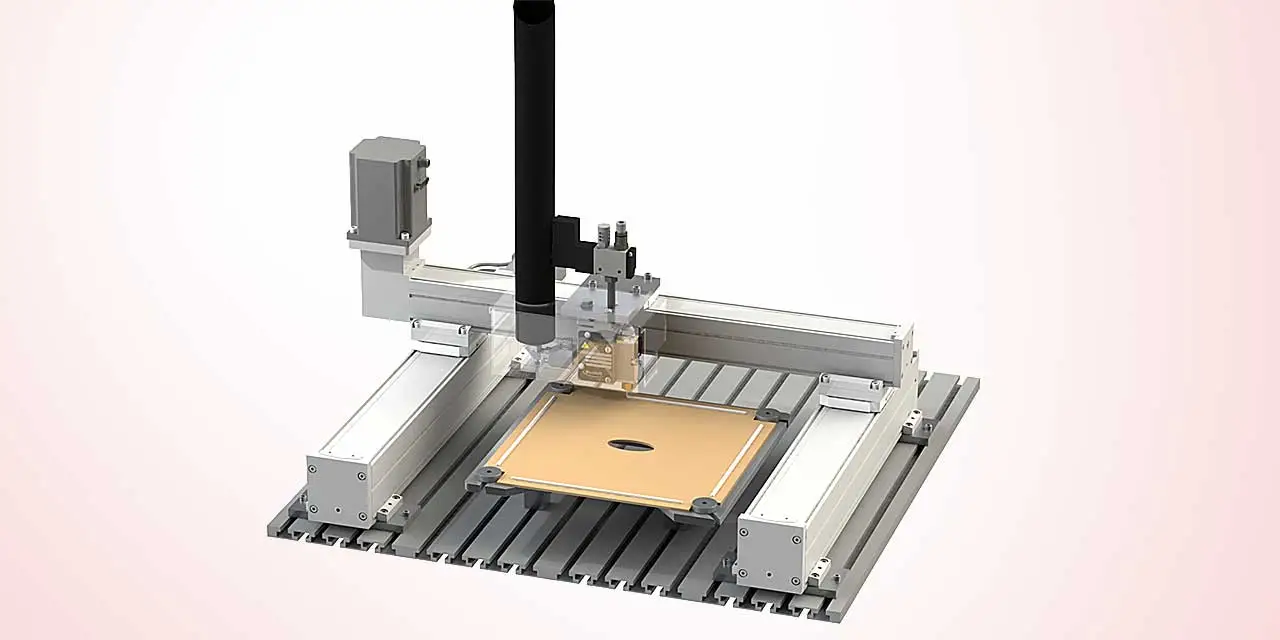

An XY plotter is a versatile and precise machine used for various applications, particularly in industries requiring accurate plotting, cutting, or gluing. The term “XY” refers to the machine’s ability to move along both horizontal (X) and vertical (Y) axes, offering precision and flexibility.

XY plotters are commonly utilized in fields like packaging, electronics, and manufacturing for tasks such as cutting intricate designs, drawing patterns, or applying adhesives with high accuracy. The integration of automatic systems in advanced models allows for enhanced automation, improving efficiency in repetitive tasks like gluing, and making them ideal for production lines.

An XY plotter is a highly adaptable machine used in several industries for tasks requiring precision and accuracy. Its ability to move along both the X and Y axes allows it to perform a wide range of functions, from cutting to drawing and even gluing. With advancements in automation, it has become an essential tool in various fields, contributing to increased productivity and precision in repetitive tasks.

• Packaging Industry:

For precise cutting, designing, and gluing of packaging materials.

• Electronics Manufacturing:

For accurately cutting and placing components in production lines.

• Textile Industry:

For pattern cutting in fabric and garment production.

• Printing and Graphics:

To create detailed prints, designs, and patterns with high precision.

• Automotive Manufacturing:

For cutting or gluing intricate components and patterns.

• Medical Device Manufacturing:

For the precise cutting and assembly of small components.

• Art and Design:

For creating detailed artwork or cutting designs in various materials.

XY plotters offer several key benefits, making them invaluable tools across various industries. Their ability to perform precise movements along both the X and Y axes enhances accuracy, reduces human error, and boosts overall efficiency. With automation capabilities, these machines streamline repetitive tasks, such as gluing and cutting, ensuring consistency and speed in production processes.

• Precision and Accuracy:

Achieve intricate cuts, designs, and patterns with high accuracy.

• Increased Efficiency:

Automate repetitive tasks like gluing, reducing manual labor and speeding up production.

• Cost-Effective:

Minimize material waste and production costs by ensuring precise application and cutting.

• Versatility:

Capable of handling multiple tasks, including drawing, cutting, and gluing, in a single machine.

• Consistency:

Maintain uniform results with automated processes, ensuring high-quality output every time.

• Customization:

Easily adjustable for different project needs, offering flexibility in design and production.

• High Precision:

Ensures accurate adhesive placement with minimal waste.

• Fast Operation:

Speed up production processes by replacing manual gluing.

• Versatile Application:

Handles both hot-melt and cold adhesives.

• Customization:

Can be tailored for work areas up to 2400mm X 1200mm.

• Packaging:

The SmartPlot XY Plotter ensures precise and efficient adhesive application, streamlining the packaging process for consistent, high-quality results. It reduces material wastage and improves speed, particularly in large-scale packaging operations.

• Retail (POP/POS Displays):

It is designed for creating visually appealing and precise point-of-purchase or point-of-sale displays, enhancing marketing efforts while maintaining accuracy in glue placement. This makes it ideal for retail environments requiring detailed, customized displays.

• Manufacturing (Rigid Boxes, Floor Displays):

The plotter ensures uniformity in gluing processes for the assembly of rigid boxes and floor displays. It improves efficiency and accuracy, reducing manual labor and ensuring consistent production quality in manufacturing settings. This plotter is the ideal solution for businesses looking to enhance efficiency and consistency in their gluing processes.