Automatic Gluing Machines: Enhancing Precision, Efficiency, and Bonding Strength Across Industries

Automatic Gluing Machines: Enhancing Precision, Efficiency, and Bonding Strength Across Industries

Automatic Gluing Machines: Enhancing Precision, Efficiency, and Bonding Strength Across Industries

Automatic Gluing Machines: Enhancing Precision, Efficiency, and Bonding Strength Across Industries

Where Can Automatic Gluing Machines Be Used?

Key Applications of Automatic Gluing Machines:

Benefits of Automatic Gluing Machines

1. Increased Efficiency & Speed

2. Precision & Consistency

3. Cost-Effective & Reduced Waste

4. Enhanced Automation & Productivity

5. Versatile Applications

6. Improved Workplace Safety

7. Better Bonding Strength

8. Environmentally Friendly

3 Types of Automatic Gluing Machines Preferred by the Industry

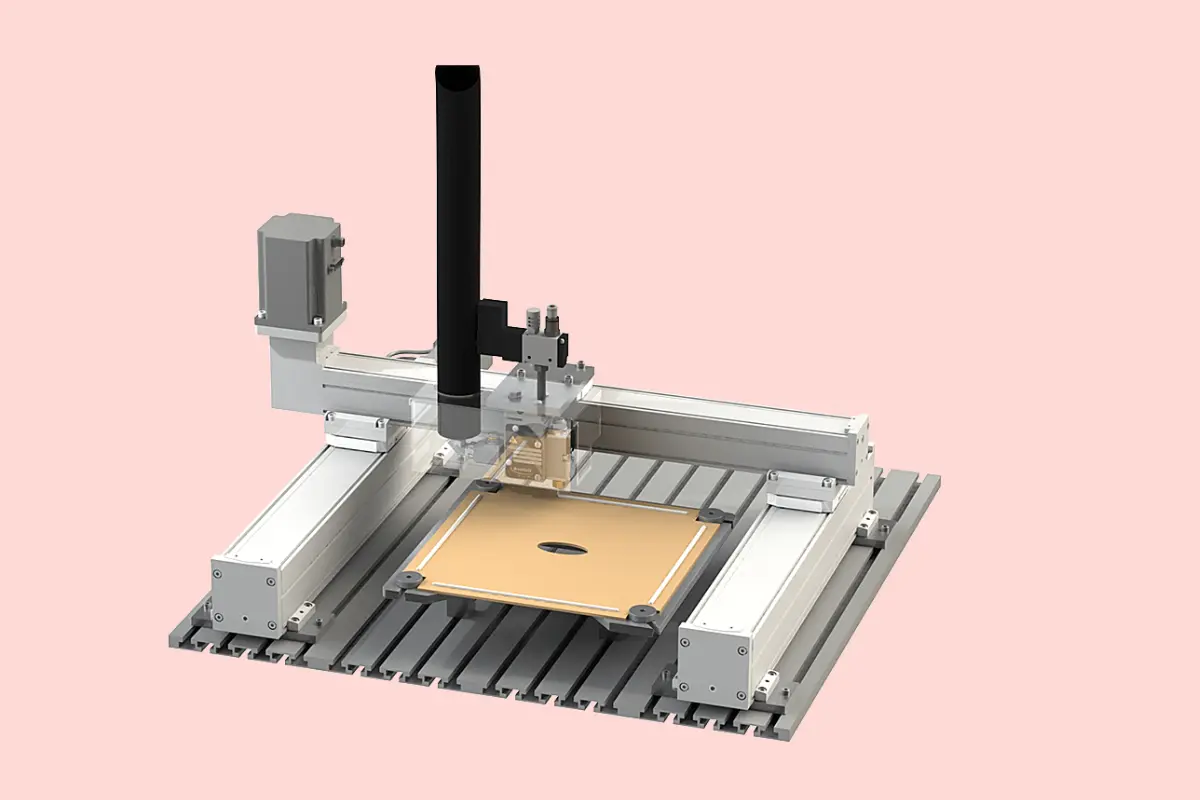

1. SmartPlot XY Plotter – Precision Glue Application Machine

Key Features:

Industries:

Applications:

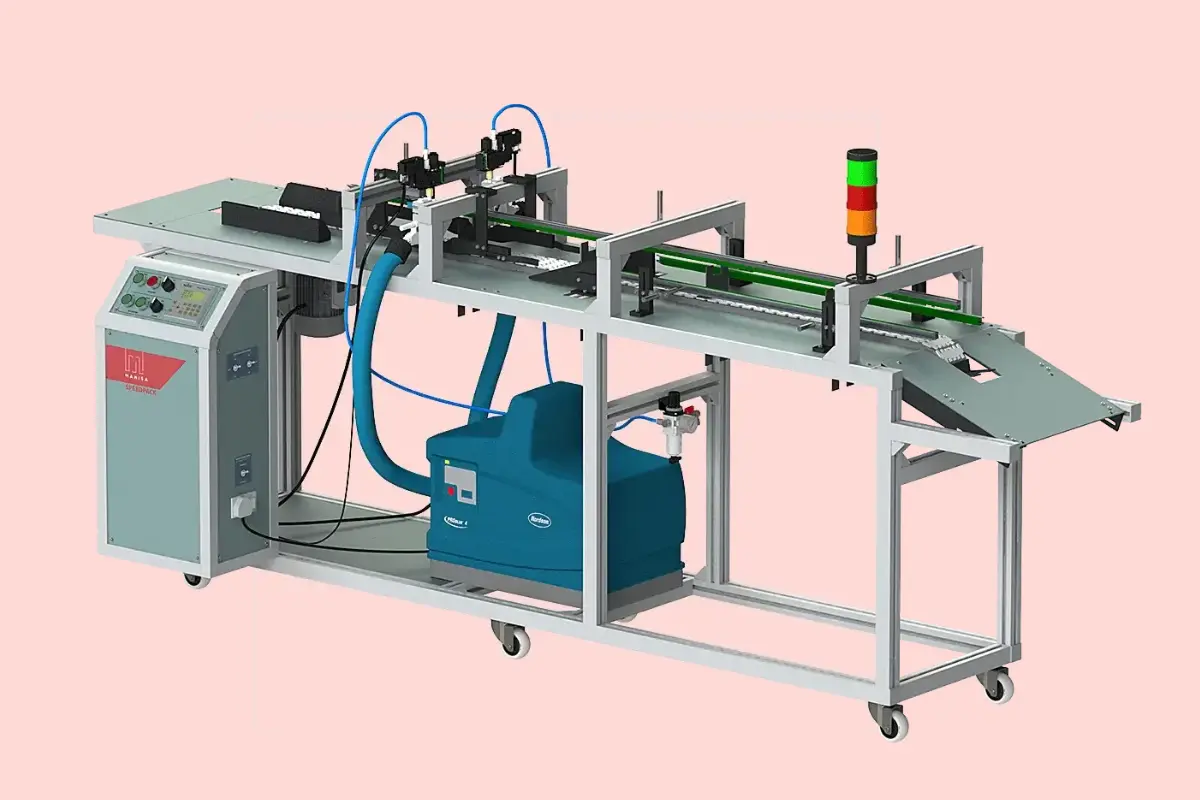

2. SpeedPack Pasting Machine – High-Speed Packaging Automation

Key Features:

Industries:

Applications:

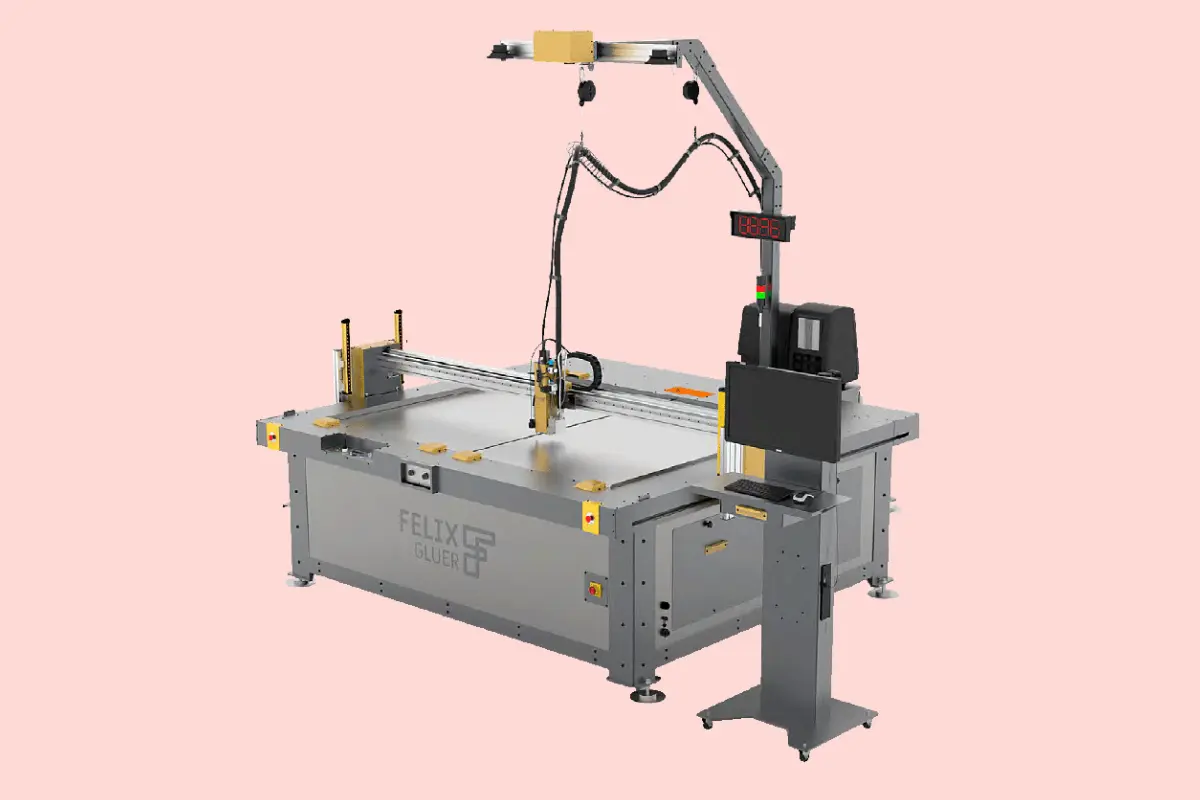

3. Felix Gluer Machine – Versatile & Strong Adhesion Solution

Key Features:

Industries:

Applications:

Conclusion

FAQ’S

How does an automatic gluing machine work?

An automatic gluing machine applies adhesive to materials using precision-controlled mechanisms.

What types of materials can be glued with an automatic gluing machine?

Automatic gluing machines can work with a wide range of materials including paper, cardboard, wood, and plastic.

Can an automatic gluing machine handle different glue viscosities?

Yes, most automatic gluing machines are equipped to adjust to various glue viscosities for optimal performance.

Is it easy to set up and operate an automatic gluing machine?

Automatic gluing machines are designed for user-friendly operation and typically come with clear instructions for setup.

What types of materials can be glued with an automatic gluing machine?

Automatic gluing machines can work with a wide range of materials including paper, cardboard, wood, and plastic.

What is the maintenance schedule like for an automatic gluing machine?

Regular cleaning and lubrication are recommended to maintain the efficiency and longevity of an automatic gluing machine.

Can an automatic gluing machine be integrated into existing production lines?

Yes, many automatic gluing machines can be customized and integrated into different types of production lines seamlessly.

Are there safety features built into automatic gluing machines?

Automatic gluing machines often come equipped with safety sensors and emergency stop buttons to ensure operator safety.

How do I choose the right automatic gluing machine for my specific needs?

Consider factors such as production volume, material type, glue application requirements, and budget when selecting the best automatic gluing machine for your business.

Mahisa Packaging Systems LLP

Office Address :

Service & Spares :

Sales Inquiry :

Sales phone: +91 98210 49426

+91 84510 70625

+91 72089 76891

Sales email: sales@mahisa.com

Social Links :

Need Help? Chat with us