Automatic pasting machine for corrugated boxes

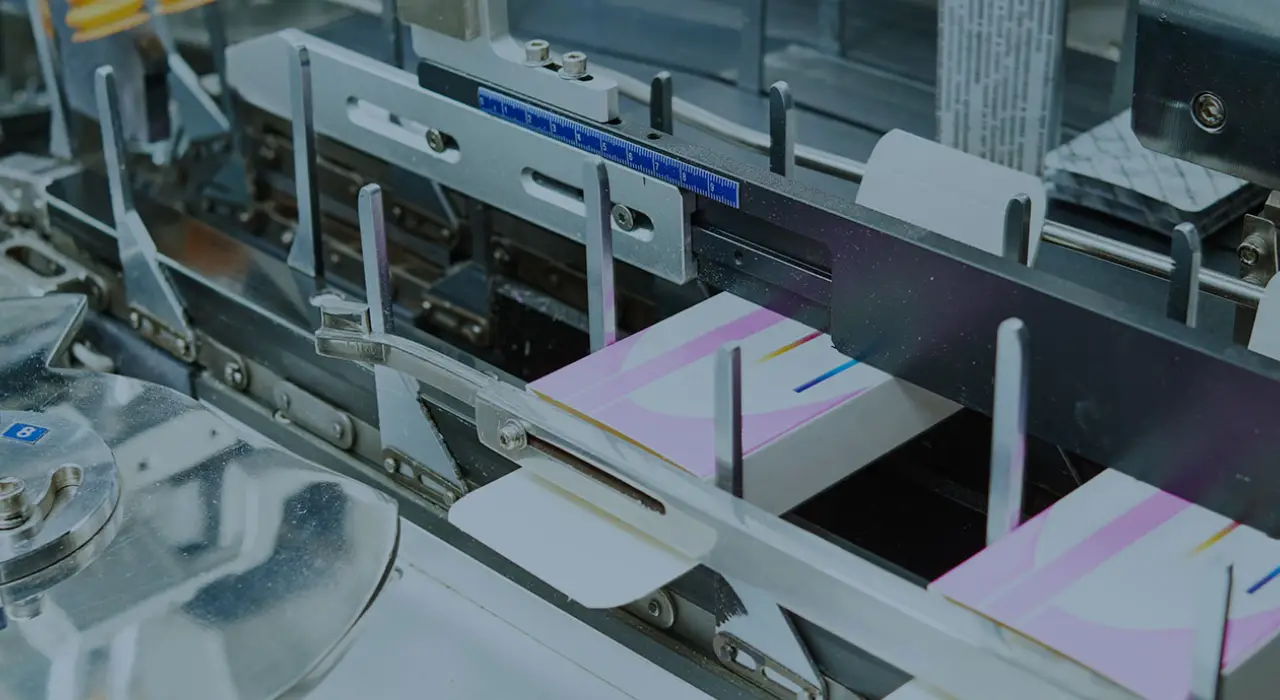

Mahisa’s Automatic Pasting Machine for corrugated boxes is a game-changer in the industry. This specialized machine streamlines the process of pasting corrugated boxes with precision and efficiency. Whether you’re dealing with large-scale production or intricate box designs, Mahisa’s Automatic Pasting Machine ensures flawless results. Trust us for top-tier solutions that redefine the corrugated boxes machine process, enhancing productivity and accuracy, making it the ideal choice for businesses seeking efficient and high-quality pasting solutions. Automatic corrugated sheet pasting machines revolutionize the sheet pasting process in the packaging industry, particularly with the integration of hot melt adhesive (HMA) technology.Box pasting machine

Mahisa’s Box Pasting Machine is the epitome of efficient corrugated box production. This specialized machine combines precision with the effectiveness of hot melt adhesive, simplifying the pasting process. Whether you’re dealing with extensive manufacturing or intricate box designs, Mahisa’s Box Pasting Machine guarantees top-notch results. When you need a reliable, efficient, and high-quality solution for box pasting with hot melt adhesive, Mahisa’s machine is your ultimate choice. By utilizing hot melt adhesive, these machines offer superior bonding strength and quick drying times, enhancing the productivity of corrugated carton box packaging processes.Glue pasting machine

Whether you’re dealing with extensive manufacturing or intricate box designs, Mahisa’s Gluing Machine guarantees impeccable results. When you require a reliable, efficient, and top-quality solution for gluing in corrugated boxes packaging, Mahisa’s machine is the ultimate choice. Trust us to meet your corrugated box packaging needs with excellence. With specific adhesive application equipment tailored for HMA adhesive, these packaging box pasting machines optimize the adhesive process, minimizing waste and maximizing efficiency.Small pasting machine

Mahisa’s Small Pasting Machine is the answer to efficient corrugated box manufacturing. This specialized machine, designed for precision, simplifies the pasting process for corrugated boxes. Whether you’re handling small-scale production or complex box designs, Mahisa’s Small Pasting Machine delivers impeccable results. When you require a reliable, efficient, and high-quality solution for small-scale box pasting in corrugated boxes manufacturing, Mahisa’s machine is the ultimate choice. Trust us to fulfill your needs with excellence. As the demand for high-quality packaging solutions continues to rise, the integration of hot melt adhesive technology in automatic corrugated sheet pasting machines underscores the industry’s commitment to innovation and excellence in packaging.Corrugation pasting machine

Mahisa’s Corrugation Pasting Machine is the cornerstone of efficient corrugated box manufacturing. This specialized machine, tailored for thermal pasting, simplifies the production process. When you need a reliable, efficient, and high-quality solution for manufacturing corrugated boxes in corrugated box production. The gluing machine, a crucial component of the automatic machinery, facilitates the even distribution of hot melt adhesive onto corrugated sheets, ensuring consistent and reliable bonding.Paper pasting machine

Mahisa’s Paper Pasting Machine is a game-changer in efficient paper pasting applications. This specialized machine simplifies the pasting process for various paper applications. Whether you’re working on intricate designs or high-volume projects, Mahisa’s Paper Pasting Machine delivers impeccable results. It revolutionizes paper pasting, enhancing productivity and precision. When you need a reliable, efficient, and high-quality solution for paper pasting, Mahisa’s machine is the ultimate choice. Trust us to meet your paper pasting needs with excellence. These machines, equipped with pasting belts and adjustable speed settings, streamline the sheet pasting process, ensuring precise application of adhesive for efficient bonding.Maximizing Productivity with Automatic Pasting Machines for Corrugated Boxes

Are you looking for an effective and efficient machine to meet your box gluing needs? If so, you’ve come to the right place. We offer a great selection of automatic pasting machines for corrugated boxes, ranging from manual to fully automatic and from mid-range to high-end. We have everything whether you need a simple or a more advanced machine. We even have a handgun dispenser to assist with small projects. Explore our range of packing machines to find the best fits your needs. These machines, specifically designed for high-speed production, streamline the process by ensuring precise and consistent application of adhesive, especially in sealing box flaps. A corrugated box flap pasting machine improves efficiency by minimizing manual labor, reducing errors, and delivering strong, durable seals that protect contents during transit.

This advanced machinery streamlines the gluing process, ensuring consistent application and strong bonds that enhance the durability of corrugated boxes. By leveraging hot melt glue, these machines offer rapid setting times and reliable adhesion, which significantly boosts production speed while minimizing waste. A packaging automation team specializes in designing and implementing automated solutions to streamline packaging processes, enhancing efficiency, consistency, and scalability in production.

Ecoplus Manual Machine

The EcoPlus range of industrial hot melt adhesive dispensing systems is designed to help users increase their productivity and product quality at an economical price. These systems use hot melt adhesives for manual application, allowing up to 750-800 parts to be processed per hour.

This product range provides an accessible entry point for industries transitioning from traditional bonding methods such as water/solvent-based adhesives, tapes, or hot glue guns. The hot melt adhesives used with EcoPlus systems can replace traditional bonding methods and strengthen bonds, making products more resilient and allowing for higher quality control. This makes EcoPlus ideal for users looking to switch to industrial hot melt adhesives.

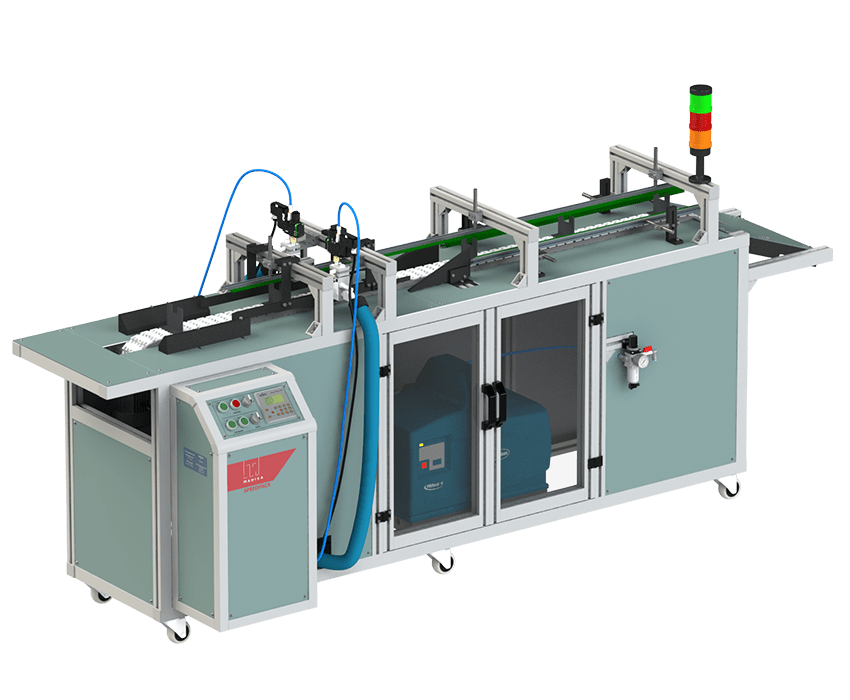

Ecostar Box Gluing Machine

Many industries are turning to hot-melt adhesive dispensers for their production processes. EcoStar is an excellent solution for just this purpose. Not only is it a cost-effective entry point, but it allows for high-quality, efficient operation. The EcoStar includes a turnkey solution with Nordson melters like OneMelt, ProBlue and Mesa and controls by Mahisa—the most trusted brand in India. The EcoStar also features state-of-the-art piston pumps, which add convenience with easy glue tank refilling and open-up applications that can use a wider range of hot-melt adhesives.

The EcoStar is designed to apply hot-melt adhesives manually and can process up to 1,500-1600 parts per hour. It is a plug-and-play system designed to be user-friendly and operated by unskilled and semi-skilled workers. It is also low maintenance and will last up to 10 years with proper service and maintenance. EcoStar is an excellent choice for those seeking a reliable and cost-effective hot-melt adhesive dispensing system for their production processes.

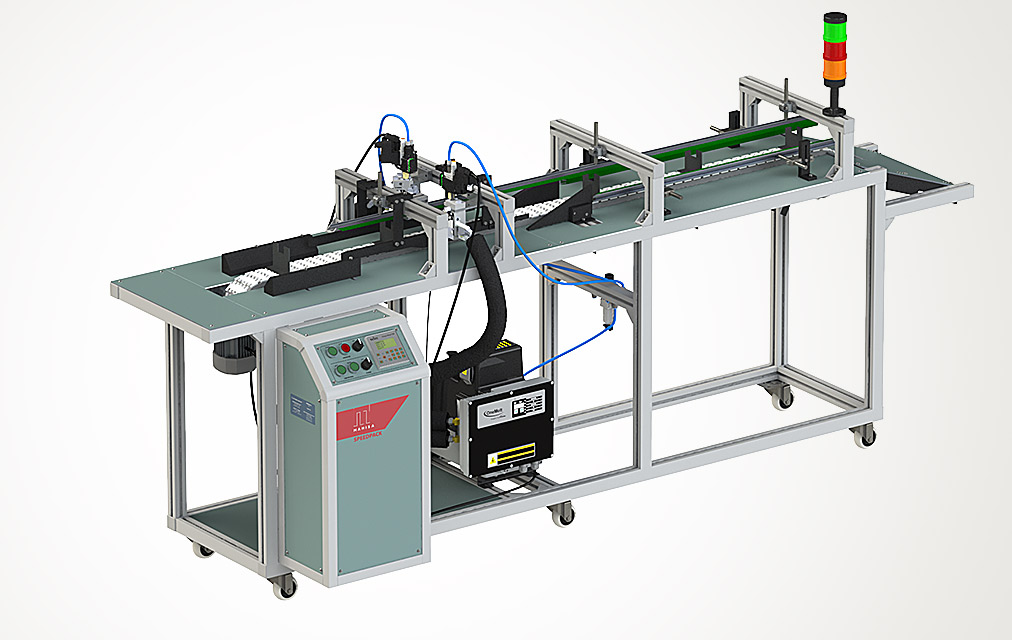

Speedpack Pasting Machine

SpeedPack’s semi-automatic continuous 2-flap gluer and folder offer a solution to fill inner cartons of various sizes manually. The hot-melt adhesive application system ensures the cartons are sealed perfectly and can achieve an output speed of up to 60 cartons per minute. In addition, the gluer and folder are customisable to process various sizes of cartons, and size changes can be executed quickly, in as little as 15 – 20 minutes, with guide settings. By introducing the SpeedPack system, organisations can achieve higher production quality and efficiency with its turnkey, compact and trouble-free operation. Further, it opens up applications to a wider range of hot-melt adhesives, making it a great addition to any packaging process.

Onemelt Handgun Dispenser

OneMelt systems offer an excellent solution for low-volume production lines. Rather than investing in expensive equipment, these systems provide an efficient and cost-effective alternative. In addition, the low melt rate of 1kg/hour eliminates the need for regular adjustments or maintenance, making them suitable even for small-scale manufacturers.

The OneMelt system also offers several economic benefits. Since it ensures accurate dispensing and better temperature control, manufacturers can experience significant adhesive savings when upgrading from a handheld cartridge gun to the OneMelt system. Additionally, the efficient energy usage and reduced charring further enhance this product’s cost-effectiveness. Overall, the OneMelt system provides a great solution for manufacturers running low-volume production lines. By replacing expensive equipment with an efficient and cost-effective alternative, manufacturers can achieve results on par with large brands without investing heavily in machinery.

Felix Gluer

Felix Gluer is designed to be simple to use so that workers don’t need to be experts in dispensing hot melt and cold glue. The user-friendly interface helps ensure a quick setup, making sure that minimal training is all that is required to get started. This makes Felix Gluer an ideal choice for those looking for a cost-effective way to replace manual gluing. In addition, the glue quality dispensed by Felix Gluer is of the highest international standards. Glue is applied with high speed and precision, meaning that production is faster than ever, eliminating time wasted with manual gluing. Furthermore, with minimal maintenance and wear and tear components, the machine can last up to 10 years with the right maintenance.

Felix Gluer is the perfect solution for businesses needing an automated gluing system. Its easy setup and reliable performance makes it ideal for high-volume manufacturing of POP/POS displays, corrugated boxes, custom packaging, foam inserts and more. With Felix Gluer, businesses can rest assured knowing that they have an automated system that makes their products faster and more precise.

This product range provides an accessible entry point for industries transitioning from traditional bonding methods such as water/solvent-based adhesives, tapes, or hot glue guns. The hot melt adhesives used with EcoPlus systems can replace traditional bonding methods and strengthen bonds, making products more resilient and allowing for higher quality control. This makes EcoPlus ideal for users looking to switch to industrial hot melt adhesives.

Selecting the right machines for food packaging is critical for ensuring efficiency, quality, and compliance with industry regulations.