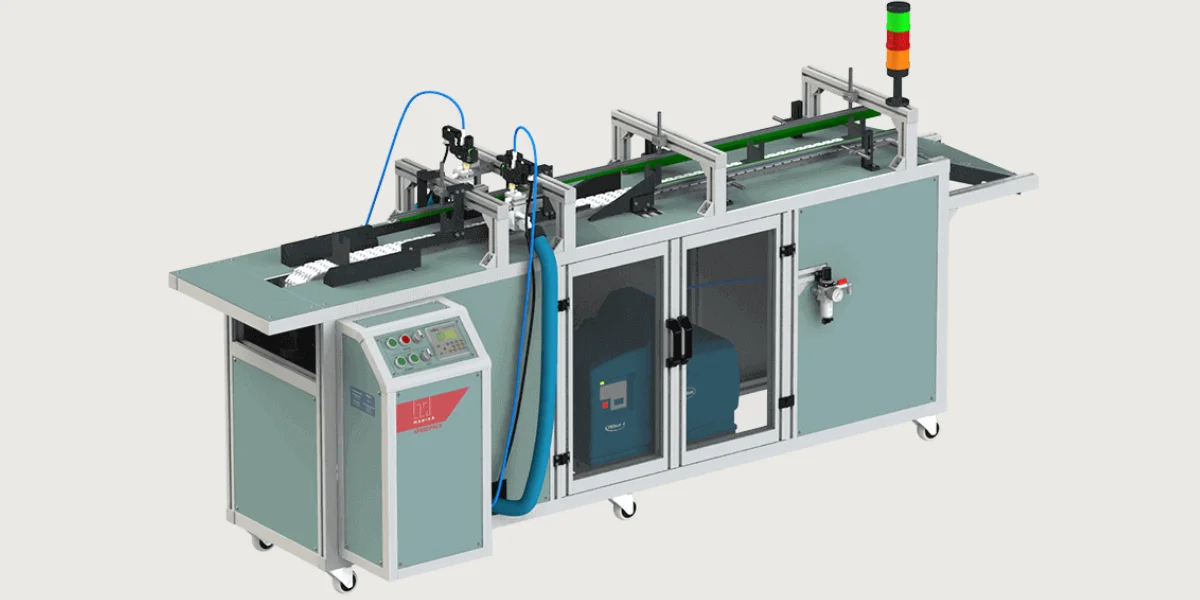

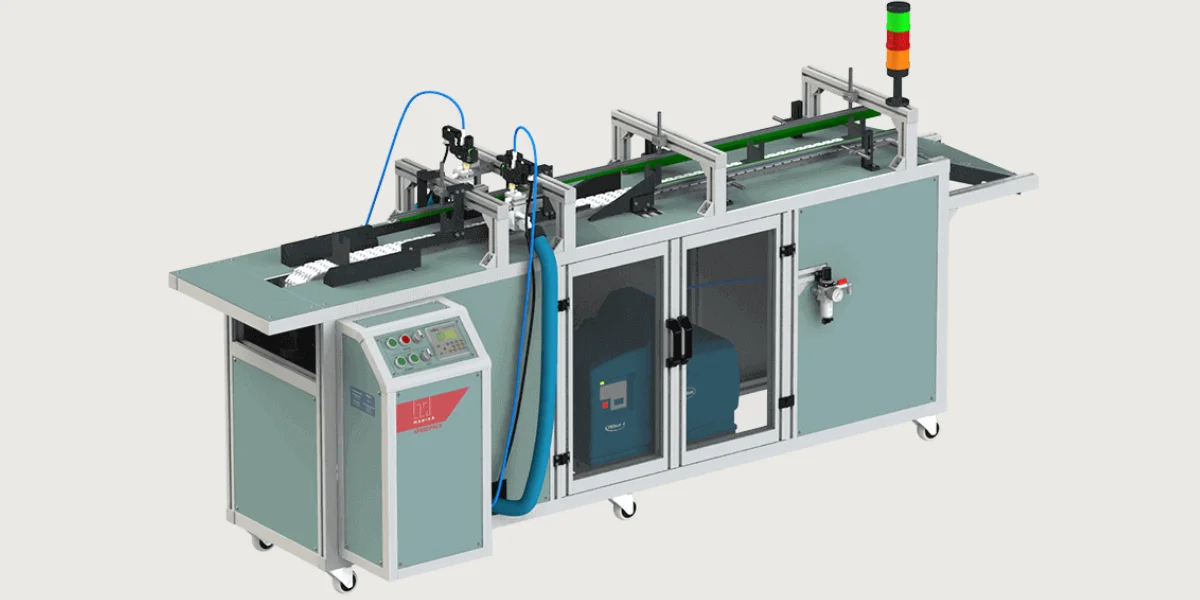

In the growing packaging automation market, efficiency and precision are key factors driving the adoption of advanced machinery. An automatic pasting machine for corrugated boxes is a crucial packaging machine designed to streamline the production process for corrugated carton box manufacturers. These machines ensure strong adhesion of corrugated sheets, improving the durability and structure of boxes used in various industries, including e-commerce, FMCG, and logistics.

With increasing demand for high-quality packaging, machine manufacturing companies are developing innovative solutions that enhance productivity while reducing manual labor and operational costs. Automatic pasting machines not only speed up the box-making process but also maintain consistency in bonding, reducing defects and waste. As businesses seek scalable and efficient packaging solutions, investing in automation has become essential for staying competitive. The right packaging machine can significantly improve workflow, making it a valuable asset for manufacturers in the corrugated packaging industry.

a. Automates the pasting process, significantly reducing production tiame.

b. Enables high-speed operation, meeting large-scale packaging demands.

a. Ensures uniform application of adhesive, improving box durability.

b. Reduces chances of weak joints, enhancing packaging strength.

a. Minimizes reliance on human effort, lowering labor costs.

b. Reduces inconsistencies and human errors, improving overall quality.

a. Optimizes adhesive usage, reducing material waste.

b. Lowers operational costs by improving efficiency and reducing rework.

a. Supports mass production to meet increasing market demands.

b. Ideal for large-scale corrugated carton box manufacturers.

a. Reduces manual handling of adhesives, preventing workplace hazards.

b. Ensures a cleaner, more organized production environment.

a. Can handle various box sizes and designs, increasing flexibility.

b. Compatible with different adhesive types for diverse packaging needs.

a. Ensures precise pasting, enhancing the overall aesthetics and functionality of boxes.

b. Helps meet industry standards for strong and reliable packaging.

Investing in an automatic pasting machine for corrugated boxes helps packaging machine manufacturing companies and corrugated carton box manufacturers improve productivity, maintain quality, and stay competitive in the growing packaging automation market.

1. High-Speed Performance:

Increases production capacity while maintaining precision.

2. Consistent Adhesion:

Ensures strong bonding, reducing defects in packaging.

3. Automation Efficiency:

Minimizes manual labor, enhancing productivity.

1. Versatile Application:

Suitable for different box sizes and designs.

2. Strong & Durable Bonds:

Optimized adhesive strength for long-lasting packaging.

3. Precision & Speed:

Ensures accurate pasting with minimal waste.

These automatic flap pasting machines help businesses streamline their packaging processes, ensuring strong and efficient bonding in corrugated box packaging.

a. Fast-drying and ideal for high-speed automation.

b. Provides strong and durable bonds for corrugated box packaging.

a. Cost-effective and environmentally friendly.

b. Ensures flexibility in bonding different packaging materials.

a. Allows repositioning before final bonding.

b. Commonly used in carton sealing machines.

a. High-strength adhesive for heavy-duty corrugated boxes.

b. Resistant to moisture and temperature variations.

a. Prevents box failure during storage and transit.

b. Enhances durability and structural integrity.

b. Reduces downtime by providing quick curing times.

a. Automated application ensures minimal adhesive wastage.

b. Improves cost-efficiency in large-scale production.

a. Provides uniform adhesion, reducing defects in packaging.

b. Maintains a clean and professional finish.

a. Water-based and biodegradable adhesives help meet environmental regulations.

b. Reduces reliance on harmful chemicals in corrugated box packaging.

b. Reduces manual labor, increasing overall productivity.