5 Best Glue Dispensing Machines for Efficient Gluing Processes

5 Best Glue Dispensing Machines for Efficient Gluing Processes

5 Best Glue Dispensing Machines for Efficient Gluing Processes

5 Best Glue Dispensing Machines for Efficient Gluing Processes

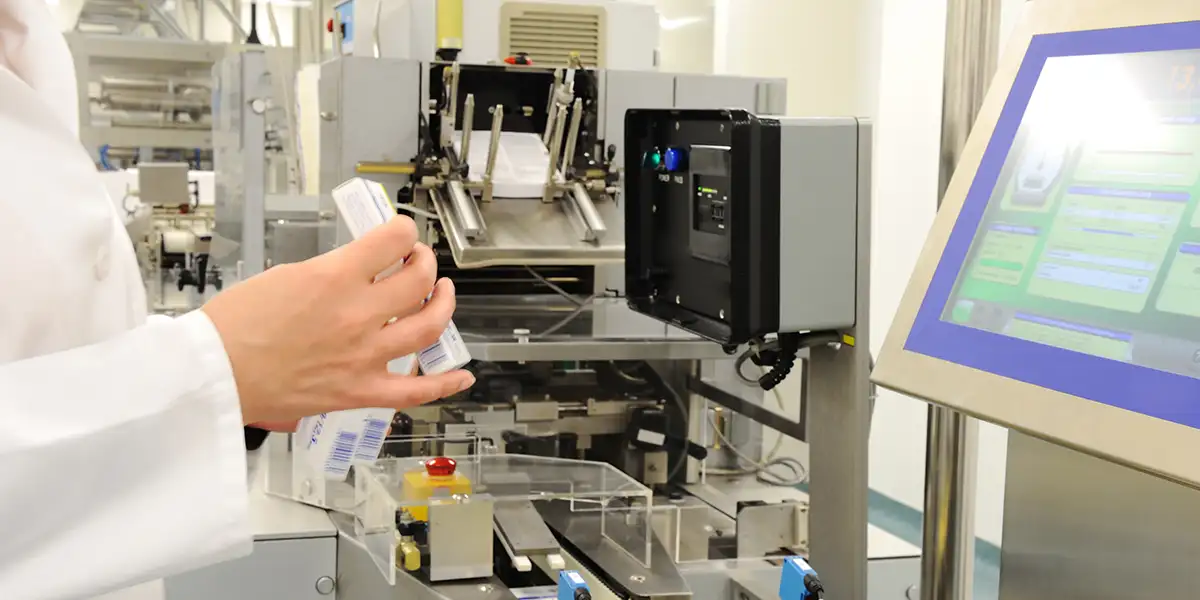

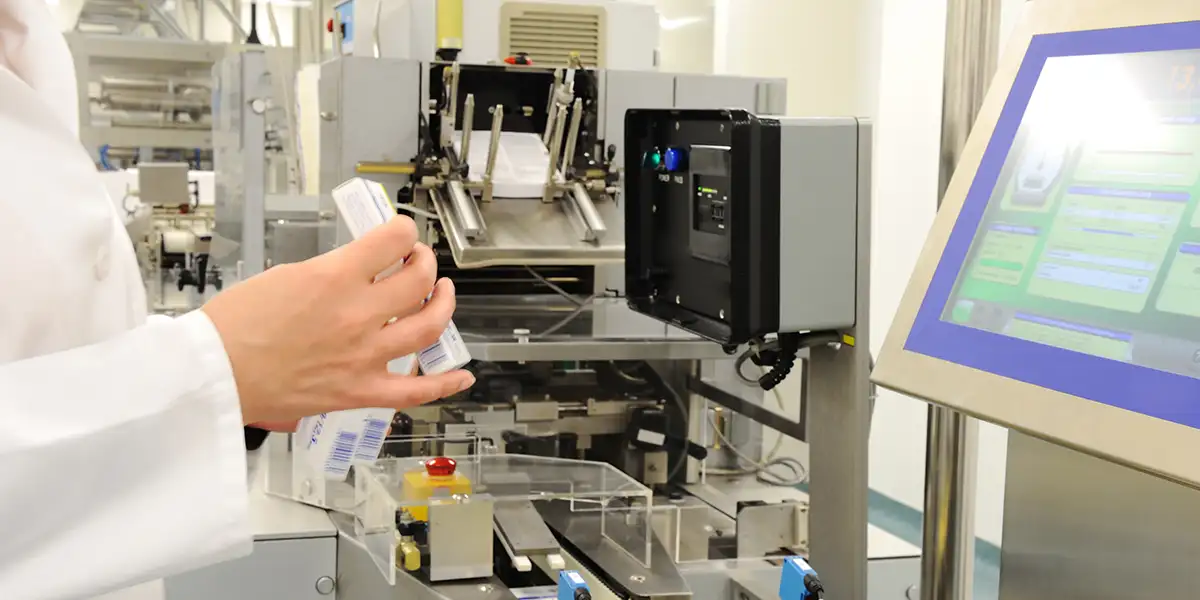

Leading packaging machine manufacturers offer advanced gluing machines designed for automated and manual applications. Key factors to consider include adhesive compatibility, dispensing accuracy, and production speed. Some of the top glue dispensing machines include EcoPlus Glue Dispenser, Ecostar gluing machine, Speedpack Machine, XY Plotter Machine, and Felix Gluer Machine. These systems optimize adhesive usage, reduce waste, and improve bonding quality.

5 Best Glue Dispensing Machines for Efficient Gluing Processes

1. EcoPlus Manual Glue Dispenser

2. EcoStar Box Gluing Machine

The EcoStar Box Gluing Machine epitomizes precision and efficiency, making it an ideal choice for businesses that prioritize both low-volume output and exceptional quality. Designed as a high-performance packaging sealing machine, it ensures consistent adhesive application, enhancing the overall gluing process.

3. SpeedPack Pasting Machine

The SpeedPack Pasting Machine revolutionizes the packaging process by seamlessly integrating efficiency and adaptability for businesses of all sizes. As a high-performance carton sealing machine, it ensures precision in adhesive application while optimizing workflow.

With an impressive output speed of up to 60 cartons per minute, this machine significantly reduces sealing time and enhances overall workplace productivity. Designed specifically for rectangular mono cartons, it delivers a robust and consistent sealing process that minimizes waste. Compatible with various types of adhesives, the SpeedPack Pasting Machine ensures strong, durable bonds, making it an essential asset for high-speed packaging operations.

4. SmartPlot XY Plotter

The Smartplot XY Plotter Machine is redefining efficiency in adhesive application for manufacturers. By utilizing advanced CNC technology, this innovative XY Plotter offers unparalleled precision, allowing for meticulous glue distribution on flat surfaces. This capability is essential in the high-volume production of retail displays, ensuring that every piece meets strict quality standards without the inconsistencies often found in manual methods.

5. Felix Gluer Machine

The Felix Gluer Machine sets a new standard in adhesive application technology, seamlessly blending speed with unparalleled precision. As an automatic glue dispensing machine, it eliminates human error and inconsistency, ensuring seamless adhesive application for various industries.

These gluing machines ensure reliability, efficiency, and cost-effectiveness in packaging production. Choosing the right hot melt glue dispenser or pasting machine from a reputable packaging machine manufacturer helps boost productivity and reduce material waste.

5 Benefits of a Glue Dispensing Machine

1. Precision & Consistency

2. Increased Efficiency & Speed

3. Reduced Material Waste

4. Enhanced Durability & Strong Bonding

Whether using hot melt adhesive dispensers or cold glue, these machines ensure optimal adhesive distribution, enhancing the strength and longevity of the final product.

5. Versatility for Various Industries

Conclusion

By choosing advanced solutions such as a hot melt adhesive machine from a trusted packaging machine manufacturer, businesses can enhance productivity, reduce material waste, and achieve consistent, high-quality bonding. Explore Mahisa’s dispensing machines to find the perfect fit for your packaging and manufacturing needs.

FAQ

What is a dispensing machine?

A dispensing machine is an automated system designed to accurately release a specific quantity of a product, such as adhesives, glue, liquids, or other materials, in various industrial applications.

How do dispensing machines improve productivity?

Dispensing machines enhance productivity by ensuring precise application, reducing material waste, minimizing errors, and increasing operational speed, which helps businesses streamline their manufacturing processes.

What industries use dispensing machines?

Dispensing machines are widely used in industries such as automotive, electronics, packaging, healthcare, food processing, and retail due to their accuracy and efficiency.

What are the types of dispensing machines available?

The most common types of dispensing machines include manual glue dispensers, automated adhesive dispensers, hot-melt glue dispensers, liquid dispensing systems, and CNC-based dispensing machines.

What is the difference between manual and automated dispensing machines?

Manual dispensing machines require human intervention for operation, while automated dispensing machines use programmed systems for precise, consistent, and high-speed dispensing, reducing human errors and labor costs.

How do hot-melt glue dispensers work?

Hot-melt glue dispensers heat adhesive material to a liquid state and apply it in a controlled manner to ensure strong bonding for packaging, woodworking, and manufacturing applications.

What are the benefits of using an automated adhesive dispensing system?

Automated adhesive dispensing systems offer benefits such as increased precision, reduced waste, faster production, cost savings, and improved product quality.

How do I choose the right dispensing machine for my business?

Consider factors such as the type of material to be dispensed, production volume, accuracy requirements, budget, and compatibility with existing workflows before selecting a dispensing machine.

How does a dispensing machine impact cost savings?

By reducing manual labor, minimizing material wastage, and increasing production speed, dispensing machines contribute to significant cost savings for businesses.

Related BLOG

Follow Us

Mahisa Packaging Systems LLP

Office Address :

Service & Spares :

Sales Inquiry :

Sales phone: +91 98210 49426

+91 84510 70625

+91 72089 76891

Sales email: sales@mahisa.com

Social Links :

Need Help? Chat with us