EcoPlus Manual Glue dispenser

Introducing Mahisa’s EcoPlus Manual Glue dispenser, a game-changer in adhesive application. This precision-engineered device comes with a versatile glue dispenser nozzle, making it perfect for various applications. As a leading hot melt glue dispenser in India, it ensures efficient and controlled adhesive distribution for tasks like box gluing and packing. The manual glue spreader is intuitive and user-friendly, providing seamless operations. Whether it’s for small-scale or large-scale projects, Mahisa’s manual glue dispensing machine offers reliability and accuracy. Trust in Mahisa’s EcoPlus for superior hot melt adhesive application, setting a new standard in manual glue dispensers. Elevate your packing processes with this cutting-edge solution. The Ecoplus manual glue dispenser by Mahisa Packaging stands out as the best manual glue dispenser in the industry, designed to meet the diverse needs of businesses that demand precision and efficiency in their packaging processes.Glue dispenser machine

Mahisa’s EcoPlus Manual Glue dispenser is a game-changer in adhesive application. This versatile glue dispenser machine offers precise and controlled adhesive distribution, ideal for various applications in carton box manufacturing and packing. The manual dispenser provides an intuitive, user-friendly experience, ensuring seamless operations. Whether for cold glue or hot glue strength, Mahisa’s gluing machine is designed to meet diverse needs. With superior dispensing equipment, Mahisa ensures efficiency in every application. Trust EcoPlus for a reliable cold glue dispenser, setting a new standard in manual gluing technology. Elevate your packing machine processes with Mahisa’s cutting-edge solution, a must-have for carton box manufacturing. Engineered with a vacuum pressure setting, this liquid glue dispenser offers unparalleled control over adhesive application, ensuring consistent results across various packaging tasks. The glue dispenser nozzle minimizes wastage while providing a smooth and even distribution of glue, making it an ideal choice for a manual box gluing machine.Glue dispensing machine

Mahisa’s EcoPlus Manual Glue dispenser redefines adhesive application. This state-of-the-art glue dispensing machine offers precision and control, catering to various glue types for packaging needs. Perfect for both manual and automatic dispensing, it’s a versatile solution for volume production. Mahisa’s manual glue dispensing machine products stand out for their efficiency and reliability. Whether it’s for cold or hot glue, this dispenser ensures seamless operations in packaging glue applications. While it excels in manual operation, it also seamlessly transforms into an automatic dispenser when needed. As a leading supplier of hot glue dispensers, Mahisa Packaging has established itself as a trusted manufacturer and supplier of glue dispensing solutions, including the hot melt glue dispenser in India. The Ecoplus manual glue dispenser is part of a broader range of adhesive dispenser machines that cater to different industry needs, from hot melt glue dispenser machines to hot melt adhesive dispensers.Hot gluing machine

The Ecoplus glue dispenser machine has revolutionized the packaging industry with its cost-effective and efficient performance. With its ability to dispense hot glue quickly and accurately, this machine is a game-changer for businesses looking to streamline their packaging processes without breaking the bank. By utilizing this hot gluing machine, companies can reduce waste and minimize errors in their packaging operations, ultimately improving overall efficiency and customer satisfaction. This hot melt dispensing machine offers an affordable solution for businesses in need of reliable hot gluing capabilities. Mahisa Packaging’s commitment to quality is evident in their hot melt glue machines, which are built for durability and reliability. As hot melt glue machine manufacturers, they offer a wide array of hot melt glue dispensing equipment designed to meet the highest standards of performance.Dispenser machine

Mahisa’s EcoPlus Manual Glue dispenser redefines adhesive application. This versatile adhesive glue dispenser machine offers precision and control, making it indispensable in various industries. The EcoPlus Manual Glue dispenser excels in hot gluing machine, ensuring a seamless and efficient process. It handles different types of adhesives, including liquid glue, with ease. Perfect for carton box packing and other industrial packaging needs, Mahisa’s dispenser machine sets a new standard in adhesive technology. Elevate your production process with Mahisa’s cutting-edge EcoPlus Manual Glue dispenser, a testament to innovation and excellence in industrial packaging equipment. Their expertise as a manufacturer and supplier of glue dispensing machines ensures that each product, including the Ecoplus manual glue dispenser, meets the specific requirements of their clients. Whether you’re looking for an adhesive dispensing machine for intricate tasks or a robust hot melt dispenser machine for high-volume applications, Mahisa Packaging has the solution.Manual glue dispenser

Mahisa’s EcoPlus Manual Glue dispenser is a pinnacle of adhesive application technology. This versatile industrial glue dispenser handles transparent liquid glue with precision, making it an invaluable tool for box gluing machine, especially in corrugated carton box production. The manual glue dispenser machine ensures seamless operations, offering control and accuracy in every application. The Ecoplus manual glue dispenser by Mahisa Packaging represents a breakthrough in adhesive dispensing technology, crafted by a leading manufacturer of hot glue dispensers. Known for precision and ease of use, this dispenser is ideal for industries that require reliable bonding solutions.Manual box gluing machine

Mahisa’s EcoPlus Manual Glue dispenser emerges as a game-changer in adhesive technology. This gluing machine for boxes proves indispensable in corrugated box production, ensuring precise flap pasting. The hot glue liquid is handled with expert precision, guaranteeing strong and reliable bonds. Mahisa’s EcoPlus boasts an impressive production capacity, making it an ideal choice for high-demand environments. Specifically tailored for carton box production, this hot melt gluing machine excels in corrugated box flap pasting. With Mahisa’s EcoPlus, the complexities of corrugated box flap pasting machine are streamlined, leading to heightened productivity and impeccable results. Mahisa Packaging, a prominent name among glue dispensing machine manufacturers, ensures that the Ecoplus model stands out with its advanced features and user-friendly design. As a trusted manufacturer of glue dispensing machines, they focus on delivering high-quality adhesive dispensing machines that meet the needs of various packaging applications.Glue applicator machine

Mahisa’s EcoPlus Manual Glue dispenser is a pinnacle of adhesive technology. Specifically designed for packaging carton boxes, this hot melt glue applicator machine ensures precise and robust bonding. With manual glue dispensing machine options, Mahisa offers versatility and control in adhesive application. The manual hot melt applicator stands out for its efficiency and accuracy, making it an indispensable tool in packaging operations. This glue applicator machine exemplifies Mahisa’s commitment to excellence, guaranteeing impeccable glue bonding for carton boxes. With a strong reputation in the industry, Mahisa Packaging excels as a manufacture & supplier of glue dispensers, offering robust and reliable solutions for different packaging needs.Modernisation

starts here!

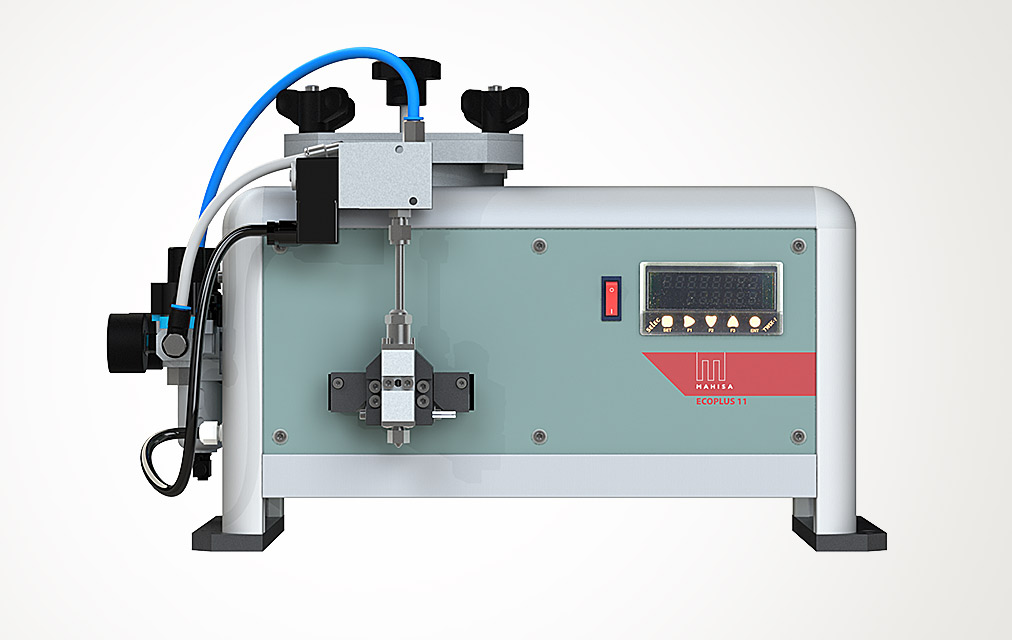

EcoPlus

Manual hot-melt adhesive dispensing

EcoPlus

Simple. Economical.

EcoPlus is an economical range of industrial hot melt adhesive dispensing systems. They are used for the manual application of hot melt adhesives to replace production processes where traditional bonding methods such as water/solvent based adhesives, tapes or hot glue guns are used. Depending on the product and application, about 750-800 parts can be processed per hour using the EcoPlus hot-melt adhesive dispensing systems.

They are designed for applications where the customer is looking to dramatically increase their production quality and efficiency by replacing their existing traditional bonding methods at a low-cost entry point. This product range is for industries looking to begin the use of industrial hot melt adhesives and reap its benefits. It is the only Indian entry-level product for industrial hot melt adhesive dispensing requirements.

The EcoPlus systems are ready-to-use, plug-and-play, user friendly equipment and can be operated by unskilled and semi-skilled workers. The product requires minimum maintenance if used in the appropriate conditions. When well-maintained, these hot melt adhesive dispensing systems can perform for over 10 years as they have minimal wear and tear components.

EcoPlus is an economical range of industrial hot-melt adhesive dispensing systems. They are used for the manual application of hot-melt adhesives to replace production processes where traditional bonding methods such as water/solvent based adhesives, tapes or hot-glue guns are used. Depending on the product and application, about 750-800 parts can be processed per hour using the EcoPlus hot-melt adhesive dispensing systems.

They are designed for applications where the customer is looking to dramatically increase their production quality and efficiency by replacing their existing traditional bonding methods at a low-cost entry point. This product range is for industries looking to begin the use of industrial hot-melt adhesives and reap its benefits. It is the only Indian entry-level product for industrial hot-melt adhesive dispensing requirements.

The EcoPlus systems are ready-to-use, plug-and-play, user friendly equipment and can be operated by unskilled and semi-skilled workers. The product requires minimum maintenance if used in the appropriate conditions. When well-maintained, these hot-melt adhesive dispensing systems can perform for over 10 years as they have minimal wear and tear components.

Read more

solution

Understanding EcoPlus better!

- Compact and economical solution.

- Fast consistent gluing.

- Quick & easy installation.

- Simple operation, minimal supervision

- Zero wastage.

- Low maintenance costs.

- EcoPlus 11: 1-liter tank with one connection for applicator head

- EcoPlus 32: 3-liter tank with two connections (one on each side) for applicator heads.

- Non-stick coated tank with open top access allows easy, clean filling.

- Tank is directly pressurized for glue dispensing; up to 3 bar pressure.

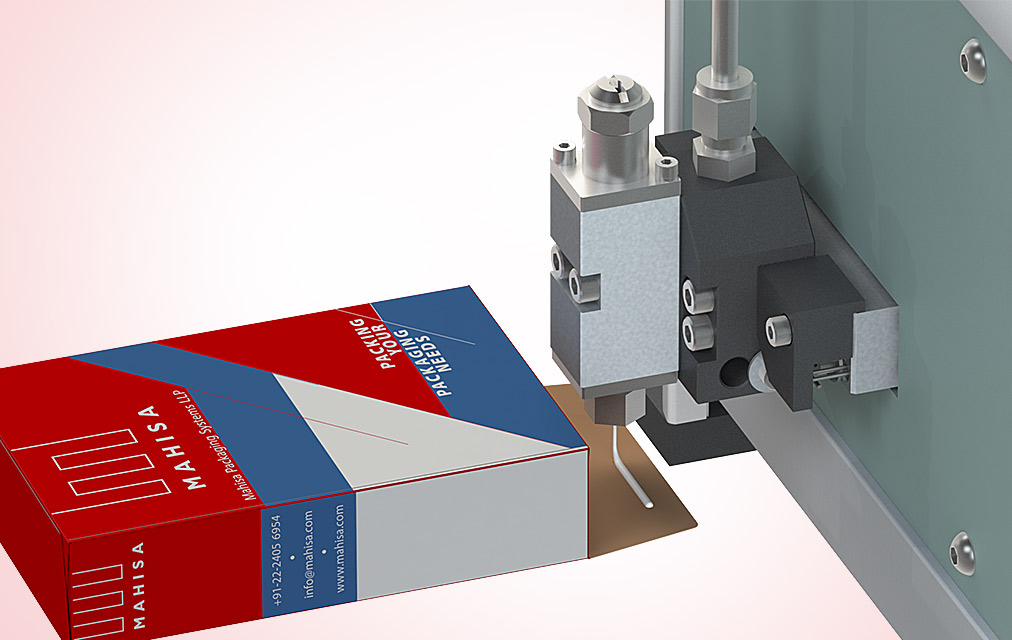

- Air-Open / Spring-Close Ball & Seat module design.

- Application tailored mounting of applicator head.

- Multiple module adaptability; up to 4 modules per applicator head.

- PLC with in-built HMI Glue dispensing.

- activation/control using foot-operated switch, sensor or PLC program.

- Integrated pattern control – dispense glue as dots or lines with precise control n-built batch and master counter

- Electrical Service: 230 VAC, 1 phase, 50 Hz.

- Output Capability: 1 no. for EcoPlus 11, Max. 2 nos. for EcoPlus 32

- Heating Time: 30 minutes.

- Tank Capacity (Volume): 1L for EcoPlus 11, 3L for EcoPlus 32.

- Tank Pressure: 2 – 3 bar.

- Operating System Pressure: 4 – 5 bar.

- Control temperature Range: 20 – 185 °C.

- EcoPlus 11: 560mm L x 350mm D x 350mm H.

- EcoPlus 32: 580mm L x 400mm W x 500mm H.

- This equipment is best suited for small products that can be handled by hand. Product bonding requiring an output of 5000 to 10000 pieces per day can use these hot-melt adhesive dispensing systems.

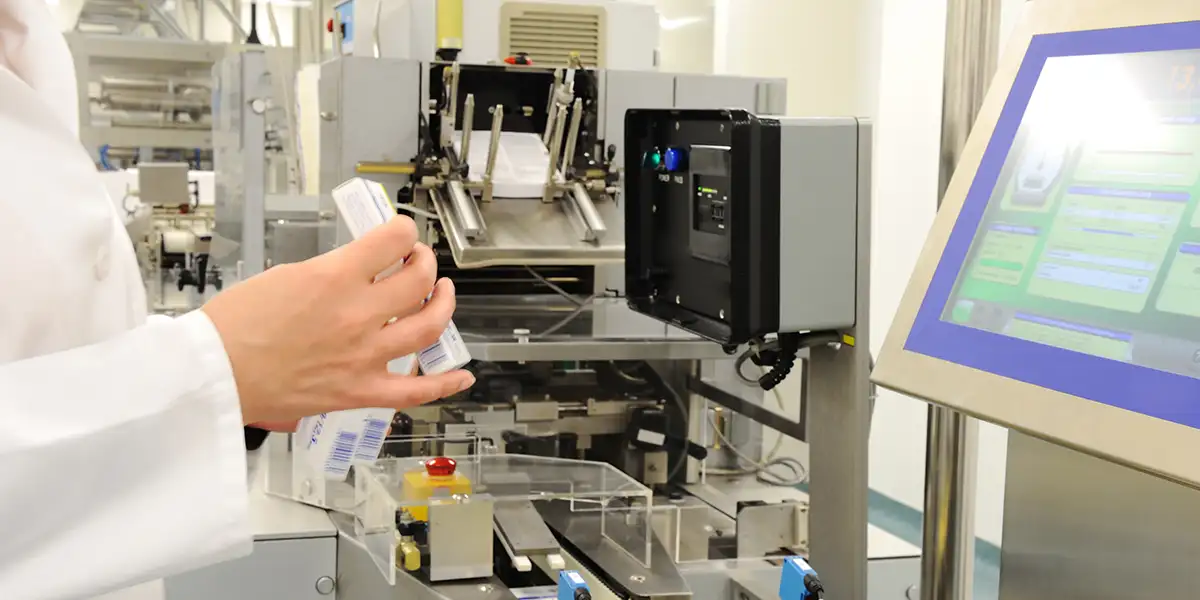

- These systems can be used in various industries requiring product bonding with hot-melt adhesives such as carton sealing, paper-board, and corrugated products manufacturing, corrugated carton manufacturing, bottle/flask caps assembly, foam, and plastic bonding such as in shoe polish, shoe shines, chemical dusters & scrubbers, and, scented candles manufacturing among others.

Features

- Compact and economical solution.

- Fast consistent gluing.

- Quick & easy installation.

- Simple operation, minimal supervision

- Zero wastage.

- Low maintenance costs.

- EcoPlus 11: 1-liter tank with one connection for applicator head

- EcoPlus 32: 3-liter tank with two connections (one on each side) for applicator heads.

- Non-stick coated tank with open top access allows easy, clean filling.

- Tank is directly pressurized for glue dispensing; up to 3 bar pressure.

- Air-Open / Spring-Close Ball & Seat module design.

- Application tailored mounting of applicator head.

- Multiple module adaptability; up to 4 modules per applicator head.

- PLC with in-built HMI Glue dispensing.

- activation/control using foot-operated switch, sensor or PLC program.

- Integrated pattern control – dispense glue as dots or lines with precise control n-built batch and master counter

Technical Specifications

- Electrical Service: 230 VAC, 1 phase, 50 Hz.

- Output Capability: 1 no. for EcoPlus 11, Max. 2 nos. for EcoPlus 32

- Heating Time: 30 minutes.

- Tank Capacity (Volume): 1L for EcoPlus 11, 3L for EcoPlus 32.

- Tank Pressure: 2 – 3 bar.

- Operating System Pressure: 4 – 5 bar.

- Control temperature Range: 20 – 185 °C.

- EcoPlus 11: 560mm L x 350mm D x 350mm H.

- EcoPlus 32: 580mm L x 400mm W x 500mm H.

Industrial Application

- This equipment is best suited for small products that can be handled by hand. Product bonding requiring an output of 5000 to 10000 pieces per day can use these hot-melt adhesive dispensing systems.

- These systems can be used in various industries requiring product bonding with hot-melt adhesives such as carton sealing, paper-board, and corrugated products manufacturing, corrugated carton manufacturing, bottle/flask caps assembly, foam, and plastic bonding such as in shoe polish, shoe shines, chemical dusters & scrubbers, and, scented candles manufacturing among others.

Image gallery for EcoPlus

EcoPlus Manual Glue dispenser

EcoPlus Manual Glue dispenser

Hot melt glue machine manufacturers

EcoPlus Manual Glue dispenser

EcoPlus Manual Glue dispenser

Hot melt glue machine manufacturers

EcoPlus Manual Glue dispenser

EcoPlus Manual Glue dispenser

Hot melt glue machine manufacturers

EcoPlus Manual Glue dispenser

EcoPlus Manual Glue dispenser

Hot melt glue machine manufacturers

EcoPlus Manual Glue dispenser

EcoPlus Manual Glue dispenser

Hot melt glue machine manufacturers

EcoPlus Manual Glue dispenser

EcoPlus Manual Glue dispenser

Hot melt glue machine manufacturers

FAQ

What is EcoPlus?

EcoPlus is a versatile and efficient hot-melt adhesive dispensing system. It is a compact, economical manual, foot-padel operated dispensing system that is ready-to-use, plug-and-play, and user-friendly. EcoPlus systems are designed to streamline adhesive application processes in various industrial settings.

How does EcoPlus improve production efficiency?

EcoPlus enhances production efficiency by providing consistent adhesive application, reducing downtime, and improving overall workflow. It offers a better solution for applying adhesives compared to traditional methods like tapes and glue guns, making it an ideal choice for industrial applications.

Is the EcoPlus system customizable? What customizations can be done with EcoPlus?

Yes, EcoPlus can be customized to meet specific application requirements. Customizations include multiple module adaptability for simultaneous drop applications, adding guides for easier adhesive application, and customizing modules/applicators for different production needs.

What safety features are included in EcoPlus?

EcoPlus includes several safety features to protect users and ensure safe operation:

Stainless steel covers over applicator heads to prevent direct contact with heated surfaces.

Pressure relief valves to prevent system pressures from exceeding recommended values.

Temperature setting lock to ensure system temperatures stay within safe limits.

Adhesive output lock if actual temperatures exceed set or recommended values.

Thermal switch on the tank to prevent overheating in case of component failure.

Voltage surge and short circuit protected relays for heating control.

Voltage protection relay that switches off mains input to the equipment in case of over- or under-supply voltage.

Additional design features to minimize the risk of failure or injury due to heated adhesive or surfaces.

What is the output that can be achieved using EcoPlus?

EcoPlus can significantly speed up processes compared to manual methods. For tasks such as carton sealing and handling small parts, the system can achieve speeds of 750-800 parts per hour.

What types of adhesives can be used with EcoPlus?

EcoPlus is compatible with various hot-melt adhesives, including EVA and metallocene-based adhesives with viscosities up to 2000-2500 cps.

What is the warranty period for EcoPlus?

EcoPlus comes with a six-month warranty from the date of dispatch, covering manufacturing defects.

What are the installation requirements for EcoPlus?

Installation requirements for EcoPlus include a stable power supply, a compressed air supply, appropriate ventilation and sufficient workspace for operation and maintenance.

Blogs You May Like..

see EcoPlus