Plastic bonding

Mahisa is dedicated to combating pollution with plastic through its plastic adhesive solutions and the versatile plastic glue gun. Their plastic glue gun and plastic adhesive solutions address the pressing issue of pollution with plastic. These solutions excel in plastic-to-plastic bonding adhesive applications, ensuring sheets of plastic bond securely. Mahisa’s commitment to addressing pollution with plastic is clear in their eco-friendly approach, providing efficient and reliable adhesive solutions tailored to reduce waste and promote sustainability. By facilitating strong bonds between plastic materials, Mahisa contributes to enhanced product durability while simultaneously advancing environmental responsibility, positioning itself as a trusted ally in the ongoing battle against plastic pollution. Plastic bonding reaches new heights with specialized adhesives, and choosing the right glue for bonding plastic is crucial for durable connections. Discover the strength of purpose-designed glue for hard plastic, formulated to create robust and lasting bonds. Mahisa’s epoxy glue for plastic stands out as a game-changer in plastic bonding technology.Plastic adhesive glue

Mahisa’s plastic adhesive glue is a potent weapon against pollution by plastic. Specifically planned for plastic-to-plastic glue bonding, this adhesive accommodates various plastic types and uses, making it the best plastic adhesive choice. Mahisa’s unwavering commitment to combating pollution by plastic is clear in their eco-friendly solution. Whether for product assembly or repairs, its versatile application promotes sustainability while reducing waste. Mahisa’s plastic adhesive glue is a vital step toward a cleaner, greener future in the fight against plastic-related pollution, and it stands as a symbol of responsible plastic use. By facilitating strong plastic glue bonding, Mahisa’s adhesive reduces waste and minimizes the environmental impact of plastic. Mahisa’s commitment to addressing pollution by plastic through responsible use for plastic makes their adhesive a crucial component for a cleaner and more sustainable future. Revolutionize your plastic bonding projects with Mahisa’s Liquid Epoxy Glue for Plastic, a breakthrough solution tailored to meet the diverse needs of modern applications. This specialized adhesive is designed to create robust bonds on various plastic types, ensuring durability and longevity. Mahisa’s Liquid Epoxy Glue for Plastic excels in bonding colored plastics, offering a seamless and clear finish that enhances the aesthetic appeal of your projects.Plastic bonding glue

Mahisa’s plastic bonding glue offers a robust solution for various applications, from securing plastic box to industrial plastic glue requirements. Their advanced plastics bonding system accommodates different types of plastic glue, ensuring strong bonds. Whether you need a plastic glue stick for quick fixes or you are working with materials like plastic water bottles, Mahisa’s expertise in adhesive technology shines through. Their commitment to delivering effective plastic bonding solutions contributes to product integrity, sustainability, and waste reduction. Mahisa’s adhesive products play a pivotal role in diverse industries, showcasing the versatility and reliability needed for the challenges of modern plastic bonding. Unlock the potential of seamless plastic bonding with Mahisa’s Hot Melt Adhesives, engineered for a reliable and enduring adhesive bond. Tailored to cater to the unique characteristics of specific plastics, this advanced solution ensures optimal performance across a variety of applications.Glue bonding adhesive

These adhesives are specifically designed to provide excellent adhesion, catering to different plastic quality and characteristics. An adhesive strength test can help determine the effectiveness of a chosen glue, ensuring it meets the performance standards. When working with low surface energy plastics, such as polyethylene and polypropylene, using a strong adhesive specifically planned for these materials is vital, as standard glues may not provide the desired bond strength. Products like waterproof glue for plastic and rubber also play an important role in applications exposed to moisture or varying environmental conditions. For those seeking more plastic bonding options, super glue for plastic is a popular choice because of its quick-drying properties and strong bonding capabilities. Super glue for plastic is a popular choice because of its fast curing time and strong bond strength.Strong plastic bonding glue

However, it is essential to consider the plastics being bonded, as some require specialized adhesives. Strong plastic bonding glue is essential when dealing with special plastics that have unique properties or requirements. By selecting the best plastic glue, manufacturers and DIY enthusiasts alike can ensure that their projects achieve the durability and performance, ultimately enhancing the longevity and functionality of the bonded components. Plastic bonding is a vital process in various applications, ranging from manufacturing to DIY projects, and selecting the right glue bonding adhesive can significantly affect the quality of the bond. For effective plastic bonding, understanding the materials involved is crucial, especially when working with low surface energy plastics like polyethylene or polypropylene. To overcome this, specialized adhesives that are designed for low surface energy materials are essential, ensuring good adhesion and durability in the final product.Glue for plastic to plastic bonding

Mahisa’s glue for plastic-to-plastic bonding is the cornerstone of secure and enduring connections, whether you are dealing with a common plastic bag or need the strength of the strongest plastic glue. Their acrylic plastic glue showcases advanced bonding chemistry, ensuring a reliable and lasting adhesive solution. This liquid plastic adhesive glue not only securely binds plastics together but also plays a crucial role in reducing waste and promoting sustainability. Mahisa’s commitment to delivering the strongest plastic glue underscores their dedication to quality and innovation, making them a trusted partner in various industries reliant on robust plastic-to-plastic bonding solutions. Elevate your plastic bonding endeavors with Mahisa’s Best Plastic Bonding Adhesive, a groundbreaking solution crafted for optimal performance on certain plastics. This specialized adhesive excels in creating strong bonds on clear plastics, ensuring a transparent and durable connection that meets the highest standards of quality.Plastic glue

Mahisa’s plastic glue offers a versatile and reliable solution for a wide range of applications, from mending plastic containers to enable chemical bonding of plastic materials. Their epoxy glue for plastic excels in its ability to securely and seamlessly connect plastic surfaces, even when dealing with challenging combinations like glass and plastic. The advanced chemical bonding properties of Mahisa’s plastic glue ensure strong adhesion, making it a trusted choice for various industries. Whether in repair work or manufacturing processes, Mahisa’s commitment to excellence shines through in their adhesive products, proving their dedication to providing effective solutions for complex bonding needs. Forge enduring connections with Mahisa’s superior solution for plastic bonding. Engineered to bond plastics with unparalleled strength, this cutting-edge adhesive is the key to success in most plastic bonding applications. The versatility of Mahisa’s plastic bonding solution shines in its ability to seamlessly bond many plastic substrates.Waterproof plastic glue

Mahisa’s waterproof plastic glue is a versatile adhesive planned to cater to various bonding types, ensuring durability and reliability in challenging conditions. Whether it’s metallic bonding or securing biodegradable plastic, this adhesive excels in creating strong and lasting connections. Mahisa’s commitment to sustainability is clear in their support for the recycling of plastic materials, where their waterproof plastic glue plays a crucial role in extending the life and utility of plastic products. By providing effective and eco-friendly bonding solutions, Mahisa contributes to reducing waste and promoting the responsible use of plastic, aligning perfectly with the growing need for environmentally conscious adhesive products. Plastic bonding is a crucial process in various industries, requiring the right materials to achieve effective adhesion. Choosing the best glue for plastic in India is essential for ensuring strong and reliable bonds. Among the various options, plastic bonding adhesive stands out, especially for plastic to plastic bonding adhesive applications.Plastic Bonding Essentials: Finding the Perfect Adhesive Solution

Section 1: What is plastic bonding?

Plastic bonding refers to the joining of two or more pieces of plastic materials using specialized adhesives. This technique creates a strong bond between plastics that may be difficult or impossible to achieve through mechanical fastening methods alone. By employing suitable chemical agents like plastic bonding glue or adhesive, manufacturers can create reliable bonds for various applications across industries.

Section 2: Understanding different adhesives

2) Cyanoacrylate (Super Glue): Ideal for quick repairs or small-scale projects due its instant setting properties, cyanoacrylate offers rapid bond formation between most common plastics.

Section 3: Factors affecting successful bonds

1) Surface Preparation: Surface preparation plays a vital role in achieving strong bonds. It includes cleaning, degreasing, and ensuring proper roughness or texture for optimal adhesion.

2) Compatibility: Choosing an adhesive that is compatible with both plastics being joined helps ensure reliable bonds. Different materials require specific formulations to achieve desired results.

3) Environmental Factors: Consideration must be given to factors such as temperature variations, humidity levels, UV exposure, chemical resistance requirements based on application scenarios.

Section 4: Best practices for plastic bonding

Conclusion

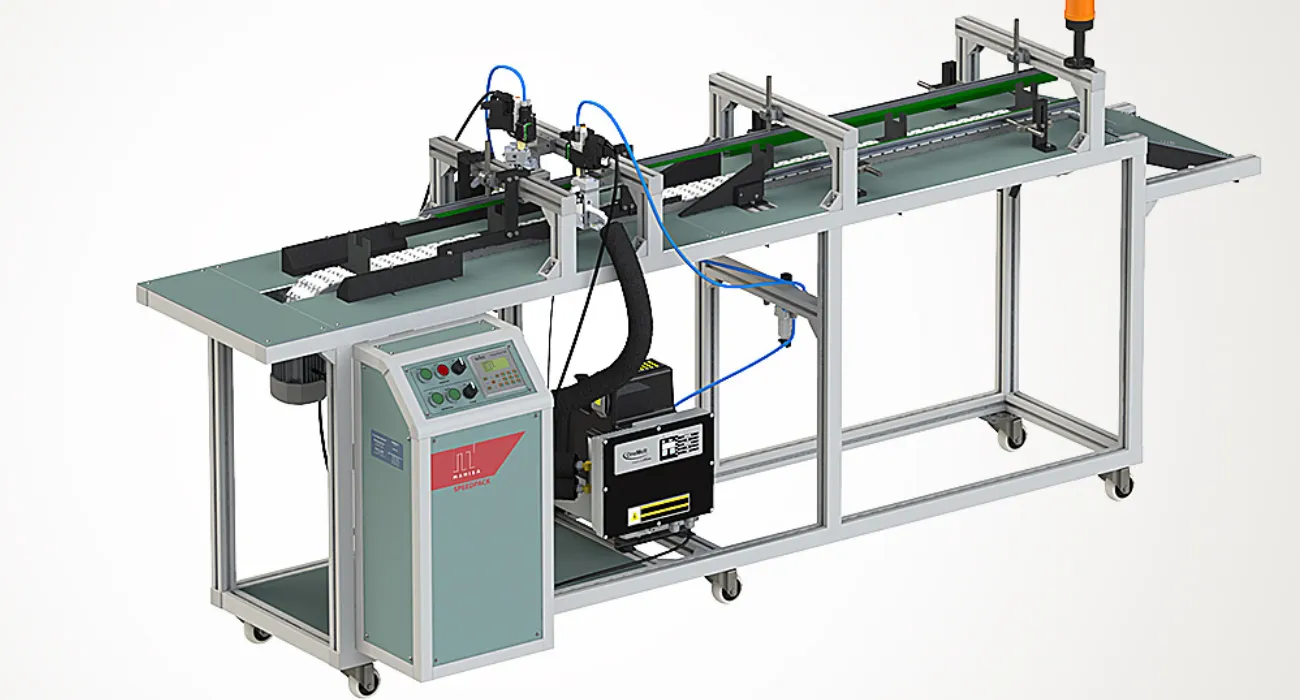

Plastic bonding offers tremendous opportunities across industries where conventional fastening methods fall short. By understanding different adhesives available along with surface preparations techniques, compatibility challenges, and best practices involved we hope this guide has equipped our industrialist readers from packaging companies packing industry professionals with necessary know-how so they make informed decisions when selecting suitable solutions their projects. At Mahisa Packaging, we pride ourselves on providing high-quality packaging solutions backed by groundbreaking technologies, including plastic-to-plastic-bonding processes. Adhering to recommended procedures will undoubtedly lead us towards enhanced innovation, sustainable development and increased customer satisfaction in the years ahead.

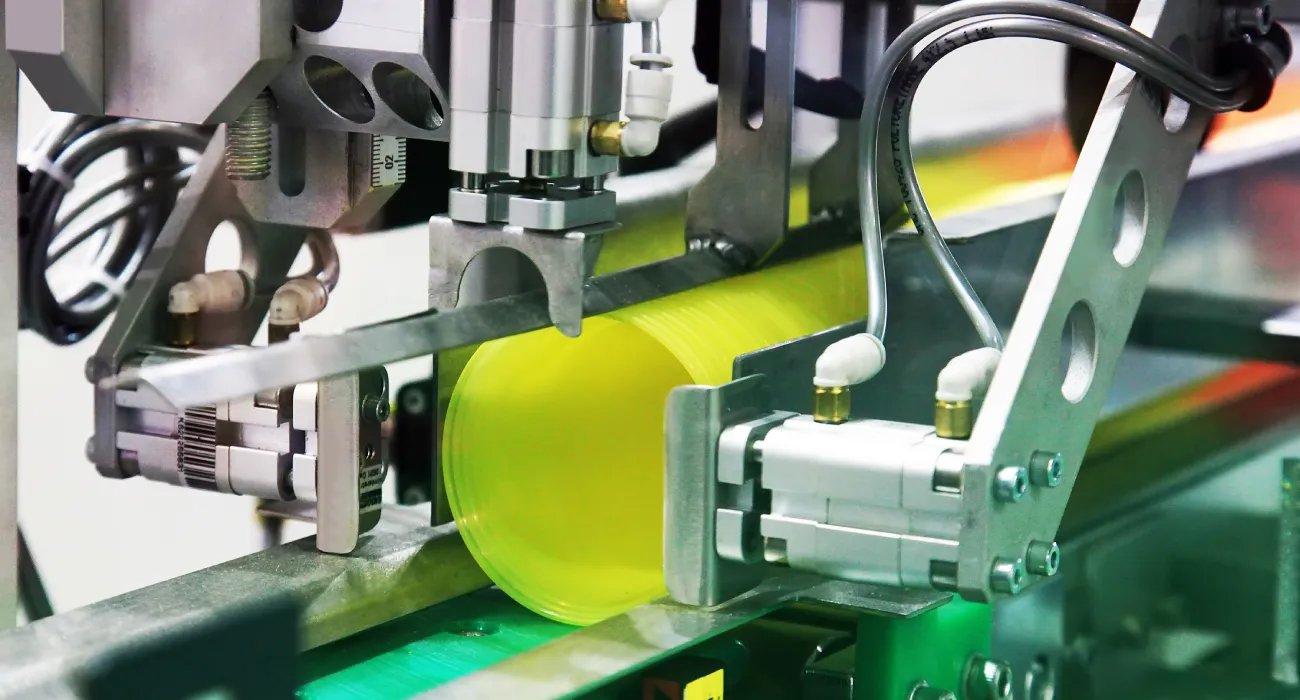

When selecting an adhesive, consider a manual glue dispenser machine for precision. It ensures controlled application, especially for complex plastic bonding, delivering efficient and consistent results for durable connections.