7 Futuristic Trends Shaping the Glue Dispensing Industry in 2025

7 Futuristic Trends Shaping the Glue Dispensing Industry in 2025

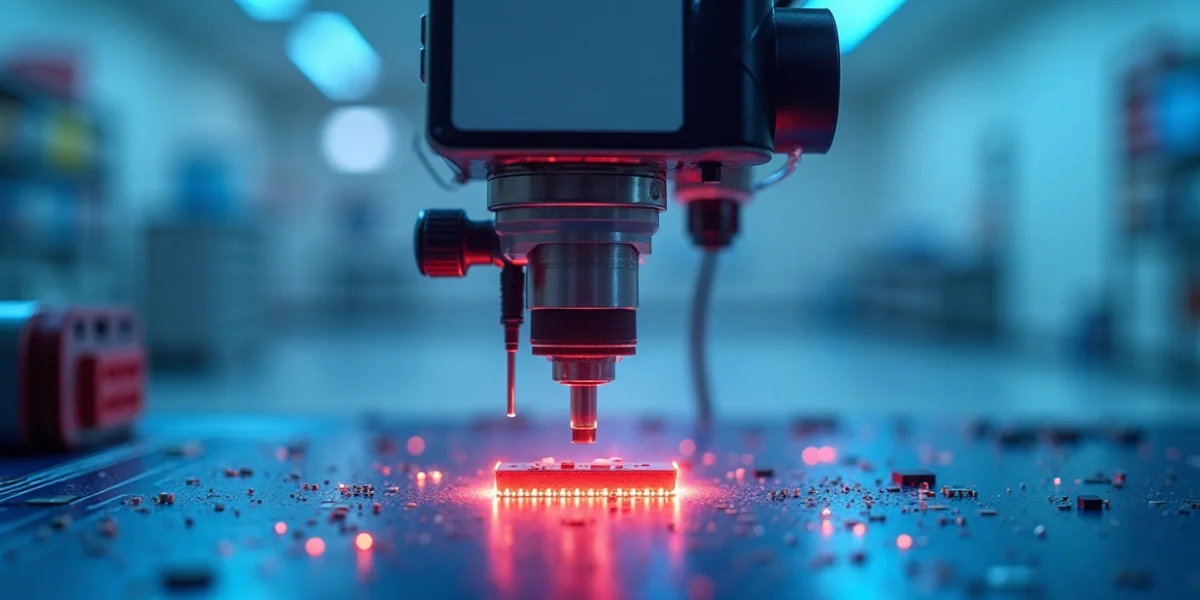

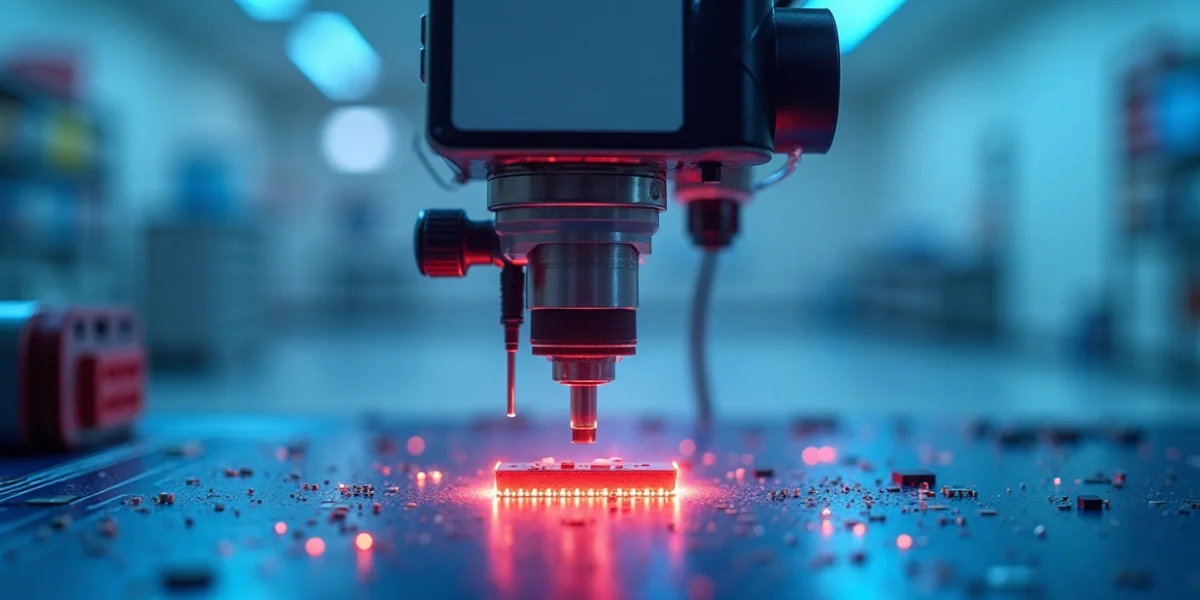

glue dispensing unit plays a critical role in modern manufacturing by ensuring precise and consistent glue application across a wide range of industries. As automated adhesive dispensing systems become increasingly prevalent, businesses are turning to advanced solutions that enhance efficiency, reduce waste, and maintain uniformity in the gluing process. The rise in demand is also driving growth in the adhesive dispensing equipment market, especially in sectors like electronics, automotive, and packaging. From cold glue adhesive ideal for paper and cardboard to high-performance epoxy glue used in electronics and aerospace, each material requires the right adhesive dispensing nozzles and configuration. Understanding the adhesive application process is essential to achieving strong bonds and optimizing product durability. Proper selection of glue dispensing tips not only improves accuracy but also minimizes downtime during production. Investing in a reliable glue dispensing unit empowers businesses to maintain quality while adapting to increasing automation needs.

A glue dispensing unit plays a crucial role in modern assembly lines by ensuring precise application of adhesives across various substrates. Whether for electronics, packaging, or automotive parts, using the right glue dispensing equipment enhances both accuracy and efficiency in the bonding joining process. An automatic glue dispensing machine reduces manual errors, speeds up the gluing procedure adhesive manufacturing process, and ensures uniform adhesive distribution. For industries seeking reliable adhesive process solutions, integrating cold and hot glue dispensing unit systems can address varied production demands. Cold glue in particular offers eco-friendly and cost-effective benefits for applications like paper, wood, and carton sealing. Optimizing the bonding process in manufacturing requires not just precision machinery but also compatibility with the adhesive type and material surface. With advancements in glue dispensing equipment, manufacturers now experience improved throughput, minimized waste, and superior product consistency across all adhesive process solutions and bonding applications.

A glue dispensing unit plays a pivotal role in modern manufacturing by offering precise and consistent adhesive application across various industries. Advanced adhesive dispensing systems ensure controlled flow and accurate placement, reducing waste and enhancing productivity. Especially in packaging and electronics, hot melt adhesive dispensing systems have become integral because of their fast-setting properties and strength. This gluing method not only speeds up assembly but also ensures durability and a cleaner finish. With growing automation, automatic glue dispensing has transformed production lines by minimizing manual intervention and improving efficiency. Selecting the right glue and applicator combination is crucial to match substrate types and desired bond strength. Many industries now rely on hot glue techniques to achieve high-performance seals with minimal curing time. From initial application to final bonding, the glue process is optimized through innovation and precision, making the glue dispensing unit a cornerstone of efficient industrial assembly.

A glue dispensing unit plays a crucial role in modern industrial applications, streamlining the adhesive development process by providing precision and consistency in material application. Whether you’re working with a cold glue adhesive or an epoxy glue, using a high-quality adhesive dispenser ensures accurate delivery, reducing waste and enhancing the bonding in process. With the rising demand for automation, advanced adhesive dispensing equipment is now engineered to handle a range of viscosities and glue types, optimizing productivity in packaging, woodworking, and electronics industries. Using a gluing machine brings many gluing and pasting benefits, such as speed, uniformity, and improved joint strength. For heat-based bonding requirements, a hot glue dispensing machine offers reliable control and quick setting, ideal for high-speed production lines. These systems not only simplify the adhesive development process but also elevate overall manufacturing standards by ensuring clean, efficient, and durable adhesive application.

A glue dispensing unit plays a critical role in industrial adhesive applications, offering precision and control across various surfaces and materials. Trusted by many industries, top glue dispensing machine manufacturers design systems that ensure accuracy in the glue dispensing process, reducing waste and enhancing productivity. From high-end automation to entry-level models, businesses can choose from advanced glue dispensing equipment or a reliable manual glue dispensing machine, depending on their production needs. For temperature-sensitive bonding, a hot melt glue dispensing machine delivers consistent results, ideal for packaging, electronics, and woodworking sectors. The right glue applicator tool allows smooth flow and even distribution, improving adhesion and reducing errors. Understanding the glue dispensing machine process is vital for achieving seamless application and operational efficiency. Whether you operate a small-scale workshop or a large manufacturing plant, investing in the right glue dispensing unit ensures long-term reliability and performance in adhesive application systems.

A glue dispensing unit is essential for precise and efficient adhesive application in various manufacturing processes. These units handle different adhesives, including eco friendly adhesive, which ensures that your production line remains sustainable while maintaining high performance. With advancements in technology, adhesive dispensing systems have developed, offering better accuracy and faster application times. For tasks involving cold glue adhesive, the units are built to operate effectively without requiring heat, making them ideal for sensitive materials. The adhesive dispensing tips can be adjusted for varying viscosity levels, ensuring a consistent and uniform application. The epoxy glue dispensing machine is widely used for industrial bonding, offering superior durability. The adhesive glue manufacturing process is simplified with the use of an auto glue dispensing machine, which automates the dispensing process, reducing human error. Overall, the glue coating process and adhesive joining process are significantly improved with the right glue dispensing tool.

7 Futuristic Trends Shaping the Glue Dispensing Industry in 2025

7 Futuristic Trends Shaping the Glue Dispensing Industry in 2025

1. Smart Glue Dispensers with AI Integration

2. Eco-Friendly Adhesive Solutions for Sustainable Manufacturing

3. 5-Axis Glue Dispensing Technology for Complex Applications

A growing number of manufacturers are demanding hot melt adhesive machine that works seamlessly with their precision part production.

4. Integration of Glue Dispensing with 3D Printing Systems

5. Modular and Customizable Glue Dispensing Units

6. Automated Quality Control with Glue Dispensing Verification Systems

Errors in adhesive application can lead to recalls, poor performance, or warranty claims. This is where automated glue verification systems play a critical role. Using vision sensors, infrared cameras, and laser profiling, these machines can detect over- or under-dispensing in real time.

7. Energy-Efficient Glue Dispensing Machines for Industrial Use

Conclusion: Adapt or Fall Behind

Whether you’re a supplier of hot glue dispensers, a packaging automation company, or a growing manufacturer, the future lies in investing in flexible, smart, and eco-friendly glue dispensing technologies.

FAQs

What is a glue dispensing machine used for?

A glue dispensing machine is used to apply adhesives like hot melt, cold glue, or water-based glue precisely on surfaces in industries such as packaging, electronics, and automotive. It ensures consistent adhesive flow, reduced waste, and faster production.

What are the common uses of hot melt glue?

Hot melt glue is commonly used in packaging, bookbinding, woodworking, automotive assembly, and electronic components due to its fast-setting properties, strong bonding, and versatility across materials like plastic, cardboard, and metal.

What is the difference between cold glue and hot glue?

Hot glue is thermoplastic and requires heating, ideal for fast bonding. Cold glue is water-based, used for porous surfaces, and takes longer to dry. Cold glue is more eco-friendly, while hot glue offers rapid set times and stronger initial bonds.

How does a 5-axis glue dispenser work?

A 5-axis glue dispenser moves in X, Y, Z, plus two rotational axes. This allows it to apply adhesives on complex or 3D surfaces with high precision, essential for industries like electronics, automotive, and aerospace.

Are glue dispensing machines energy-efficient?

Yes, many modern glue dispensing machines feature energy-efficient components like smart heaters and standby modes. These reduce power consumption during idle time and improve operational cost efficiency for large-scale manufacturers.

What are the benefits of modular glue dispensing units?

Modular glue dispensers offer scalability, easy maintenance, and customization. They allow manufacturers to switch adhesive types or add components without replacing the entire machine—ideal for growing or multi-product businesses.

What industries use hot melt adhesive equipment?

Industries using hot melt adhesive equipment include packaging, furniture, automotive, textiles, and electronics. It’s popular due to quick drying, strong bonds, and compatibility with automation.

Mahisa Packaging Systems LLP

Office Address :

Service & Spares :

Sales Inquiry :

Sales phone: +91 98210 49426

+91 84510 70625

+91 72089 76891

Sales email: sales@mahisa.com

Social Links :

Need Help? Chat with us