Hot melt adhesives are transforming the landscape of manufacturing and assembly across various sectors, making them essential tools in modern applications. This blog will explore the diverse applications of hot melt glue, highlighting its effectiveness and adaptability in different industries. The adhesive application methods available, such as extrusion, spraying, and roll coating, allow for tailored solutions that meet specific project needs.

Understanding the necessary hot melt glue equipment—from manual guns to sophisticated automated systems—ensures that users can achieve optimal performance and efficiency. Furthermore, we will discuss the unique characteristics of adhesive, including setting time, viscosity, and bonding strength, which influence the choice of adhesive in various contexts. Join us on this journey to uncover the pivotal role hot melt adhesives play in enhancing productivity and product quality.

Understanding the characteristics of adhesives is essential, as these properties directly influence performance and product longevity. In addition, the wide range of adhesive products available showcases their adaptability in different settings and industries. Below, we explore the applications of hot melt glue across various sectors, highlighting how they enhance efficiency and effectiveness in each field.

In the packaging sector, hot melt adhesives are widely used for sealing boxes and cartons. Their quick setting time ensures that production lines run smoothly, while their strong bond effectively holds packaging materials securely in place. The adhesive properties of hot melt solutions, including their resistance to moisture and temperature fluctuations, further enhance their suitability for packaging applications.

Hot melt adhesives are essential in woodworking for assembling furniture, cabinets, and other wooden structures. Their ability to bond wood seamlessly allows for clean finishes and strong joints, enhancing the overall quality of wooden products.

In textiles, hot melt adhesives are utilized for bonding fabrics and producing non-woven materials. They enable quick assembly and finishing of garments, while also providing flexibility and durability, which are vital for clothing applications.

Hot melt adhesives contribute significantly to the automotive sector by bonding various components, such as interior panels and trim. They provide a lightweight solution that maintains structural integrity while reducing the overall weight of vehicles, improving fuel efficiency.

In electronics, hot melt adhesives are used for potting and encapsulating components, which offers protection from moisture and thermal stress. Their quick curing time supports rapid production, making them suitable for high-volume electronic assembly.

Hot melt adhesives are increasingly being used in construction for flooring installations and assembling components. Their superior bonding strength ensures durability and performance, while also allowing for flexibility in application processes.

In bookbinding, hot melt glue is a preferred choice for attaching pages and covers. It provides a clean and strong bond that maintains the integrity of the book, allowing for high-quality finished products.

Each of these industries benefits from the unique properties of hot melt adhesives, driving innovation and enhancing productivity in their respective processes.

1. Rapid Setting Time:

Hot melt adhesives bond quickly upon cooling, significantly reducing production time and increasing workflow efficiency.

2. Versatility:

These adhesives can bond a wide range of substrates, including wood, plastics, metals, and textiles, making them suitable for diverse applications.

3. Temperature Sensitivity:

Hot melt adhesives are applied in a molten state and require careful temperature control to achieve optimal adhesion and prevent thermal degradation of the materials being bonded.

4. Low Viscosity:

During application, hot melt adhesives possess a low viscosity that allows for easy and uniform spreading, ensuring consistent coverage and effective bonding.

5. High Initial Tack:

This characteristic provides a strong hold immediately after application, reducing the need for additional clamps or fasteners during the curing process.

6. Durability:

Hot melt adhesives deliver strong bonds that are resistant to moisture, heat, and shear forces, enhancing the longevity of the assembled products.

1. High Efficiency:

Capable of applying adhesives rapidly, increasing production rates significantly.

2. Consistent Application:

Ensures uniform adhesive coverage, improving product quality.

3. Automation Compatible:

Easily integrates with automated production systems, optimizing workflow.

These systems are used for applying hot melt adhesives in fine mist patterns, perfect for large surfaces and thin layers. They are ideal for projects with a need for even coverage and minimal adhesive buildup. Some common uses for spray adhesive include bonding fabrics, laminating surfaces, and attaching packaging materials. The application of adhesives through spray systems ensures uniform distribution, which enhances bonding strength and reduces material waste, making them an efficient choice in various industries.

1. Uniform Coverage:

Delivers even adhesive distribution, reducing material waste and enhancing bonding strength.

2. Flexibility:

Ideal for complex shapes and surfaces, accommodating diverse application needs.

3. Fast Application:

Speeds up the adhesion process, increasing overall productivity.

Utilized primarily in the woodworking and flooring industries, these systems apply hot melt adhesives over large areas efficiently. The roller coating process allows for high-speed applications, making it an ideal choice for production lines needing quick turnaround times. These systems are often used for coating flat targets, ensuring even coverage across wide surfaces. By employing rollers, they achieve a desired coated surface with consistent adhesive thickness, significantly enhancing quality and reducing material waste in manufacturing applications.

1. High Throughput:

Capable of high-volume production, making them ideal for large manufacturing operations.

2. Consistent Application:

Ensures uniform adhesive layers, which reduces the chances of weak bonds.

3. Reduced Waste:

Efficient material usage minimizes excess glue application, contributing to cost-effectiveness.

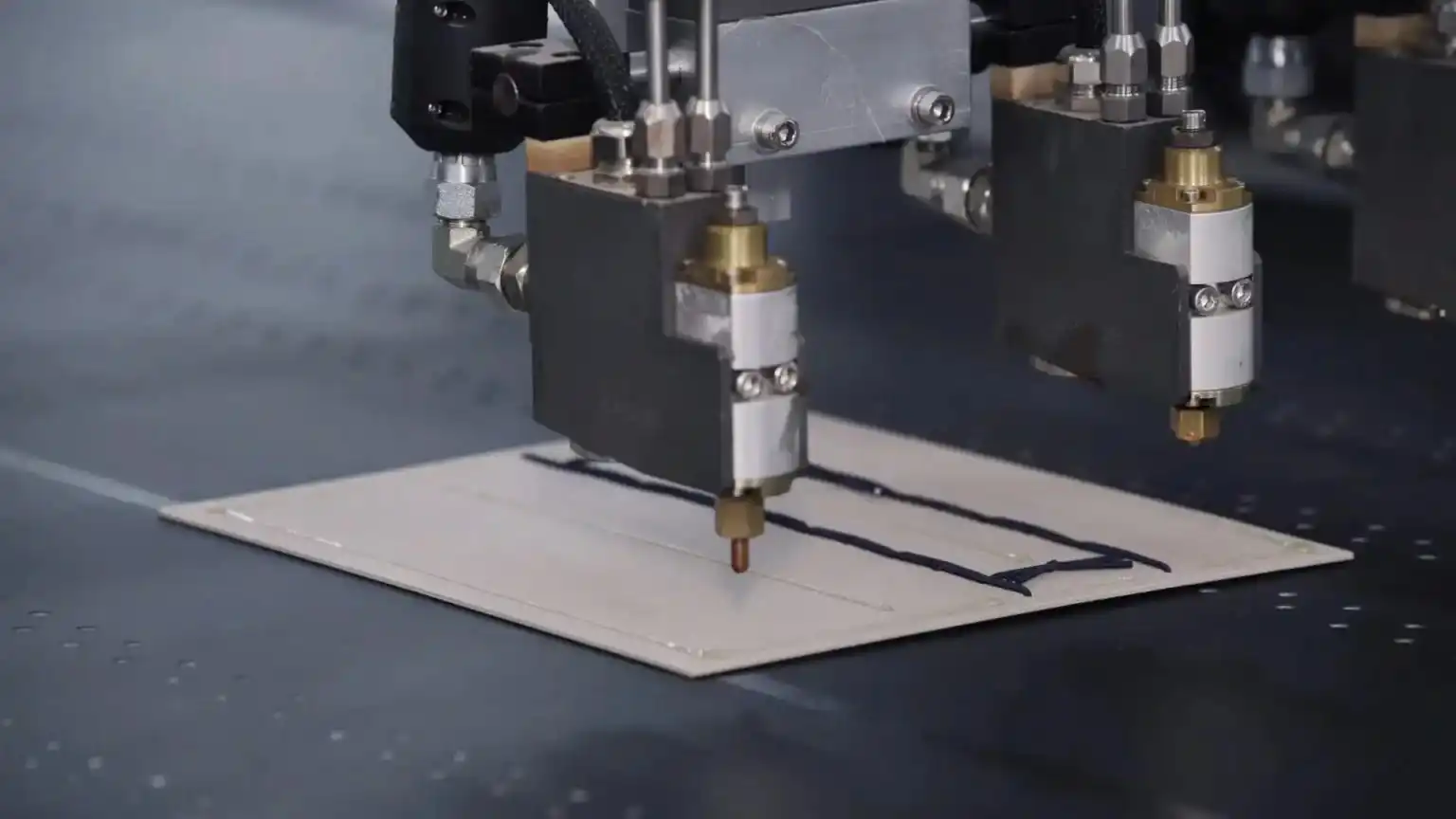

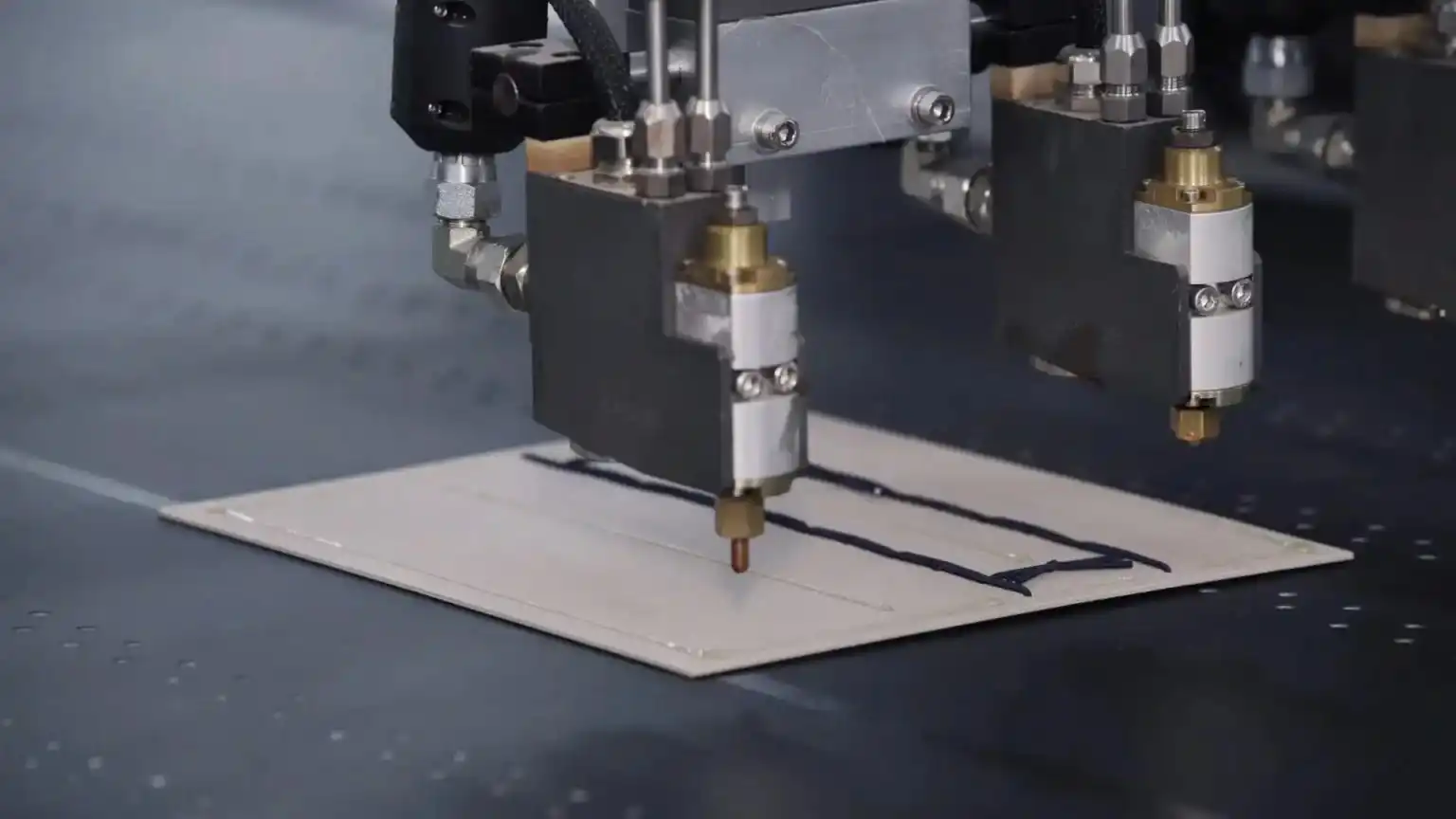

These systems expertly apply hot melt adhesives in a continuous bead, making them integral to the assembly of packaging and construction materials. Representing a specific type of application for hot melt adhesives, bead application systems optimize the bead application process to ensure smooth and uniform adhesive distribution. As a highly effective application device, they provide precise control over the adhesive flow, enhancing efficiency and bond strength in various manufacturing settings. This technology is particularly valuable in high-demand industries, ensuring that every project achieves optimal results.

1. Precision:

Allows for targeted adhesive application, reducing excess and increasing efficiency.

2. Flexibility:

Supports various bead sizes and patterns, ideal for diverse bonding requirements.

3. Integration:

Easily connects with automated systems for streamlined production processes.

The choice of the right hot melt adhesive application equipment enhances the efficacy, quality, and cost-effectiveness of manufacturing processes within the adhesives and sealants market. Understanding the characteristics of adhesives and appropriate adhesive application methods is crucial for achieving optimal results.