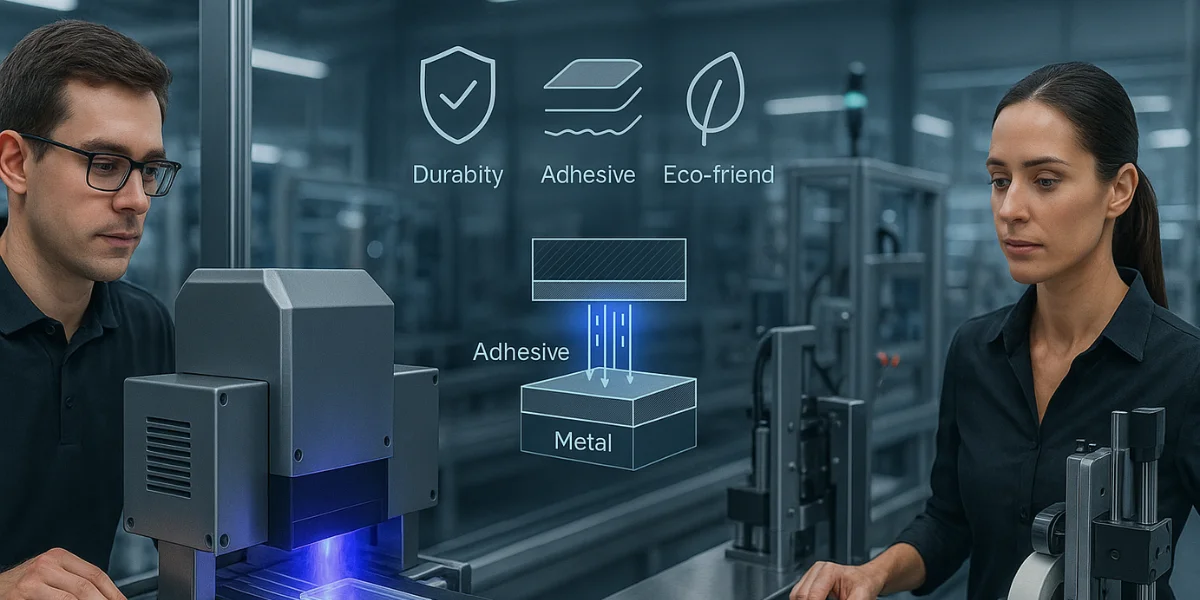

Hot melt adhesives are used across packaging, woodworking, bookbinding, textiles, electronics, and many other industries because they set quickly, bond a wide variety of materials, and are easy to handle. One variable determines whether an HMA job succeeds or fails more than almost any other: hot melt adhesive temperature. The temperature at which the adhesive is melted, applied, and cooled affects viscosity, open time, wetting, penetration, bond strength, and long-term performance. This post explains why hot melt adhesive temperature matters, how it affects the different stages of bonding, how to select the right temperatures for your process, troubleshooting tips, and best practices for consistent results.

When people talk about hot melt adhesive temperature, they usually mean three related but distinct temperatures:

1. Melting (or pot) temperature:

The temperature at which the adhesive is heated in the melter or applicator so it becomes fluid and pumpable.

2. Application (or nozzle) temperature:

The temperature at which the molten adhesive exits the applicator and contacts the substrates.

Each stage has different requirements. The pot temperature must be high enough to fully melt the polymer blend and achieve the correct viscosity for pumping. The application temperature determines how well the adhesive wets the substrates and the open time (how long it remains tacky). The cooling profile influences crystallization and internal stress development that affect bond strength.

Open time (or tack time) is the window during which substrates can be joined before the adhesive sets. Higher application temperatures typically increase open time because the adhesive starts hotter and takes longer to cool to the solidification point. Some processes need very short set times (e.g., high-speed packaging), while others benefit from longer open time (e.g., repositionable laminations). Controlling temperature lets you balance production speed and assembly flexibility.

2. Drum or tank melters for high-volume coating or extrusion may need higher pot temperatures to maintain flow.

3. Spray or curtain coating often requires lower-viscosity adhesives and thus higher pot temperatures or specialized formulations. Choosing the proper adhesive application method will guide your temperature selection.

1. High-speed lines with rapid cooling:

Use a hotter application temperature if you need rapid wetting, but rely on fast cooling to set.

2. Porous materials (paper, wood):

Allow for some penetration—slightly higher temperature or higher viscosity bead may be used depending on desired penetration depth.

3. Heat-sensitive substrates (thin plastics, coated papers):

Avoid excessive application temperature; use fast-setting adhesives with lower application temperatures or cold-glue alternatives if necessary.

Adjust application temperature and adhesive choice to get the right open time. If assemblies are misaligned or require repositioning, choose adhesives with longer open times or increase the temperature slightly within spec. For immediate conveyance, use lower-temperature, faster-setting grades.

1. EVA-based hot melts: pot 160–190°C (320–374°F), application 150–180°C (302–356°F).

2. Polyolefin/metallocene-based: pot 170–200°C (338–392°F), application 160–190°C (320–374°F).

4. Low-temp hot melts: pot 120–150°C (248–302°F), used for heat-sensitive substrates. (Note: these are typical ranges; always follow the supplier’s specified hot melt adhesive temperature range for your exact product.)

• Likely causes:

application or pot temperature too low (poor wetting), or the adhesive has degraded from excessive pot temperature.

• Fixes:

Raise pot/application temperature within supplier recommendations; ensure melter temperature is stable and adhesive is fully melted; check for degraded adhesive and replace if necessary.

• Likely causes:

the application temperature is too high or the viscosity is too low for the process.

• Fixes:

reduce application temperature; use a higher-viscosity grade or narrower nozzle; improve cooling (air knives, chill conveyor).

• Likely causes:

thermal degradation from over-temperature or long residence time.

• Fixes:

lower pot temperature; limit the time adhesive spends in the melter; clean the melter; replace adhesive if degraded.

• Likely causes:

adhesive partly solidified in lines due to low temperature or heat loss in hoses; contamination from degraded material.

• Fixes:

check hose heating, maintain recommended pot temp, clean and purge system, use proper filters and strainers.

1. Use melters and applicators with accurate, calibrated thermostats and servo-controlled heating where possible.

2. Keep hose lengths and nozzle designs optimized to minimize heat loss; use insulated or heated hoses when necessary.

3. Monitor pot residence time and use gentle agitation to prevent local overheating and degradation.

4. Maintain a cleaning and maintenance schedule: remove char and old material, change filters, and inspect heaters/thermocouples regularly.

5. Use temperature profiling and loggers on critical lines in high-volume operations to detect drift or hotspots.

6. Train operators on correct temperature settings for each adhesive and job, and document recipes (pot temp, nozzle temp, nozzle size, pressure, open time) for repeatability.

1. Low-temperature adhesives:

specialty formulations exist that melt and wet at lower temperatures for heat-sensitive substrates; use these rather than simply raising pot temps.

2. High-temperature service:

for assemblies that will experience high ambient or service temperatures, select adhesives with higher softening points and follow recommended processing temperatures to ensure the polymer morphology is appropriate.

3. Food-contact or medical applications:

adhere strictly to supplier guidance and regulatory requirements; some adhesives require specific processing windows to ensure no harmful degradation products.

Controlling hot melt adhesive temperature is critical for consistent, high-quality bonds. Temperature affects viscosity, wetting, open time, set speed, and long-term durability. Follow manufacturer recommendations, match temperature to your adhesive application method and substrates, monitor equipment, and apply disciplined maintenance and process documentation. Small temperature adjustments can markedly change process behavior and bond quality, so precise control and repeatable recipes are essential.