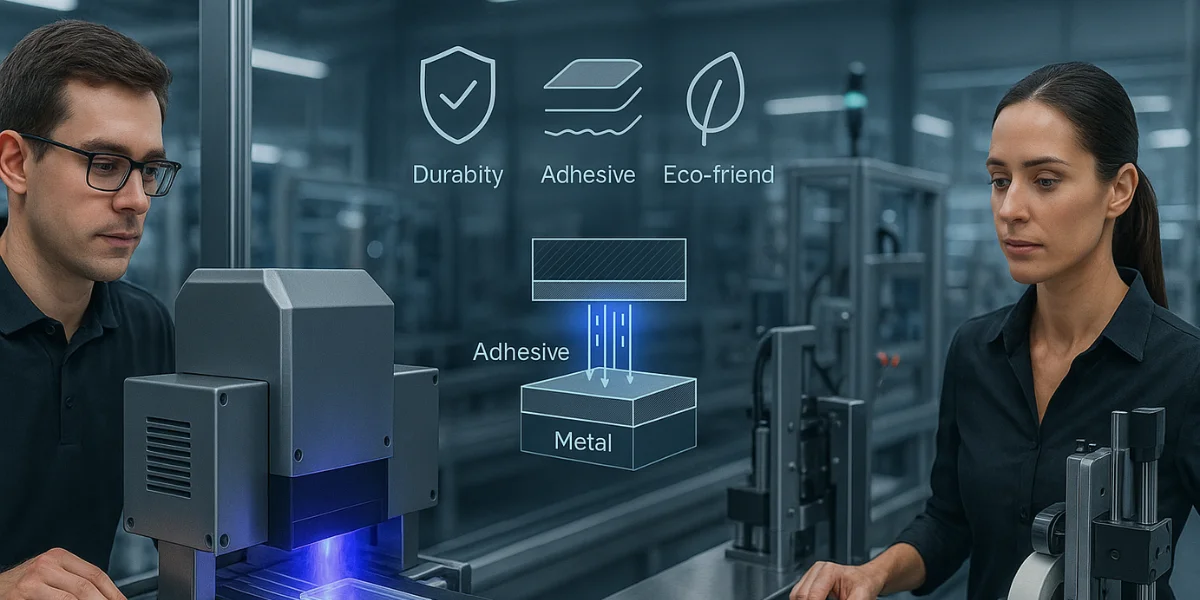

Testing hot melt adhesives is not merely a formality; it’s a critical step in ensuring the success of your products and processes. Here’s why:

1. Quality Control:

Testing ensures that each batch of HMA meets predetermined quality standards, guaranteeing consistency and reliability. This includes verifying the consistency of the hot melt adhesive composition.

2. Performance Prediction:

By evaluating various properties, testing helps predict how an HMA will perform under different conditions, allowing for informed material selection.

3. Problem Solving:

When bonding failures occur, testing can help identify the root cause, whether it’s a material defect, application issue, or environmental factor.

4. Compliance:

Many industries have specific regulatory requirements for adhesive performance. Testing ensures compliance and avoids potential legal issues.

1. Viscosity Testing:

Viscosity is a crucial property that affects the hot melt adhesive application and wetting characteristics of an HMA.

• Brookfield Viscosity:

This is a common method that measures the resistance of the HMA to flow at different temperatures and shear rates. It helps determine the optimal application temperature and predict how the adhesive will perform in dispensing equipment.

• Capillary Viscosity:

This method is used for HMAs with higher viscosities or when more precise measurements are needed. It involves forcing the molten adhesive through a capillary tube and measuring the pressure drop.

2. Thermal Properties Testing:

HMAs undergo significant temperature changes during application and service. Understanding their thermal behavior is crucial.

• Softening Point:

This test determines the temperature at which the HMA begins to soften and lose its shape. It provides an indication of the upper service temperature limit. Common methods include Ring and Ball.

• Heat Resistance (SAFT – Shear Adhesion Failure Temperature):

Measures the temperature at which an adhesive bond fails under a specific load. This test is crucial for applications where the adhesive will be exposed to elevated temperatures.

• Glass Transition Temperature (Tg):

This is the temperature at which the HMA transitions from a hard, glassy state to a more rubbery state. Tg affects the flexibility and impact resistance of the adhesive.

• Thermal Stability:

This test assesses how well the HMA resists degradation and changes in properties when exposed to prolonged heat.

3. Adhesion and Cohesion Testing:

These tests evaluate the strength and durability of the adhesive bond.

• Tensile Strength:

Measures the force required to break an adhesive bond when pulled in tension.

• Peel Strength:

Measures the force required to peel an adhesive bond apart. This test is particularly relevant for flexible substrates.

• Shear Strength:

Measures the force required to break an adhesive bond when subjected to a shear force (force applied parallel to the bonded surfaces).

• Tack:

Measures the initial stickiness of the HMA. High tack is important for applications where immediate bonding is required.

• Open Time:

This refers to the maximum time allowed between applying the adhesive and mating the substrates while still achieving a satisfactory bond.

• Set Time:

The time it takes for the adhesive to solidify and develop sufficient bond strength.

• Creep Resistance:

Measures the adhesive’s ability to resist deformation under a constant load over time. This is important for structural applications.

4. Environmental Resistance Testing:

HMAs are often exposed to harsh environmental conditions.

• Humidity Resistance:

This test evaluates how well the adhesive bond withstands exposure to high humidity levels.

• UV Resistance:

This test assesses the adhesive’s resistance to degradation from ultraviolet radiation.

• Chemical Resistance:

This test determines how well the adhesive resists exposure to various chemicals, such as solvents, acids, and bases.

5. Other Important Tests:

• Color and Clarity:

While not directly related to performance, color and clarity can be important for aesthetic reasons.

• Odor:

Odor can be a concern in some applications, particularly in consumer products.

• Density:

Density is used for calculating volume and mass relationships.

Test results should be interpreted in the context of the specific application requirements. There is no single “best” HMA for all applications. The ideal adhesive will depend on factors such as the substrates being bonded, the service temperature, the required bond strength, and the environmental conditions. Comparing test results to established benchmarks and historical data can help identify potential issues and optimize material selection.

The field of HMA testing is constantly evolving, with new technologies and techniques emerging to provide more accurate and comprehensive evaluations. Developments in areas such as non-destructive testing and advanced data analytics are paving the way for improved adhesive quality control and performance prediction. The hot melt adhesives market in India is experiencing significant growth, driven by increasing demand from the packaging, automotive, and construction industries. This growth necessitates robust testing infrastructure and adherence to international standards to ensure the quality and reliability of HMAs used in the region.

Hot Melt Adhesive Testing is a vital process for ensuring the adhesive quality, performance, and reliability of bonded products. By understanding the key tests and their significance, manufacturers can make in