Hot melt adhesives

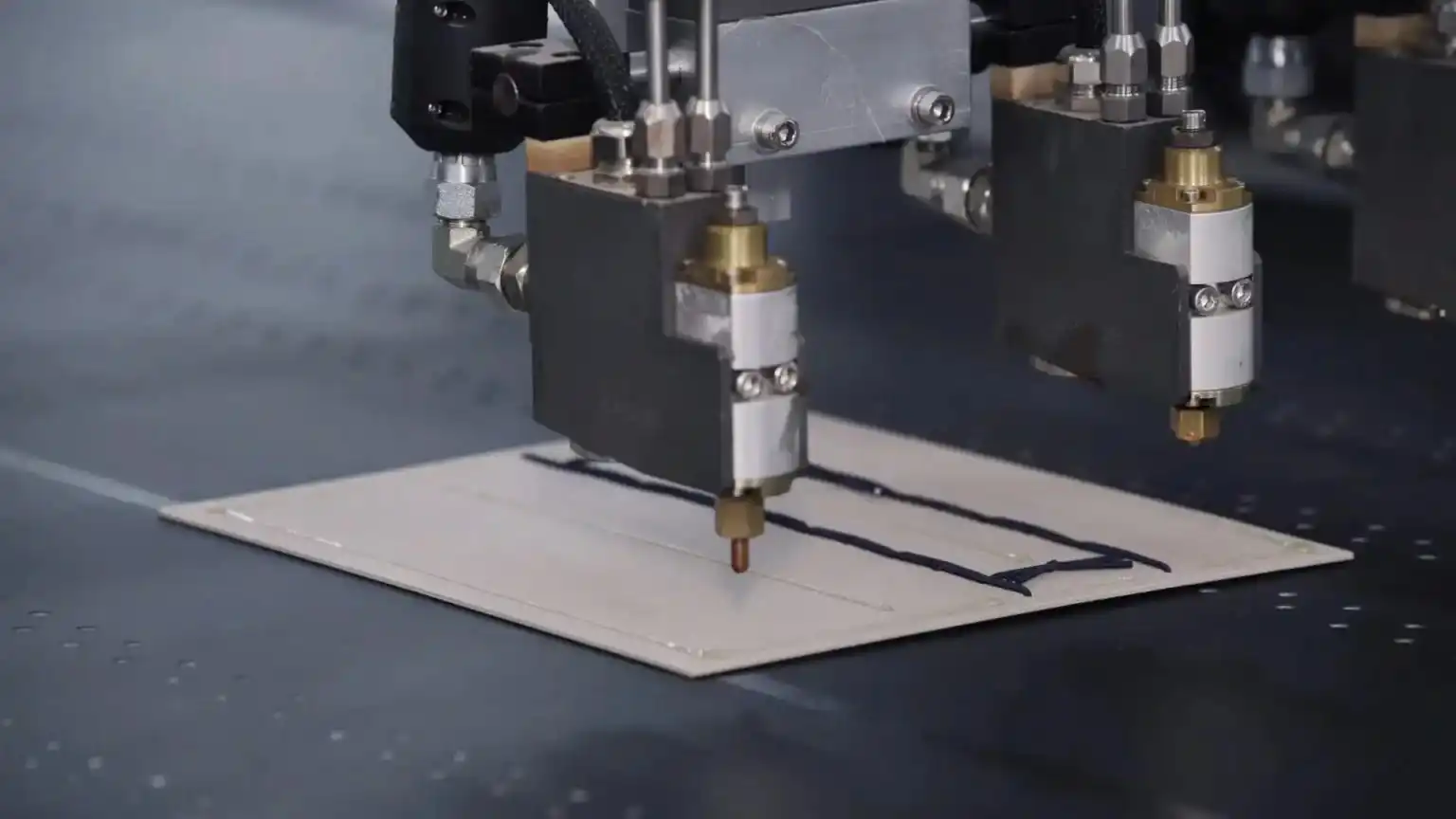

Hot melt adhesives are widely recognized for their exceptional adhesive strength and versatility, making them essential in modern packaging and product assembly. As one of the trusted hot melt adhesives manufacturers, Mahisa Packaging delivers reliable bonding solutions designed to perform under varying industrial conditions. These adhesives are applied in a molten state and solidify quickly to create durable bonds across materials such as paper, plastic, fabric, and metal. The hot melt adhesive uses extend from carton sealing and labeling to woodworking and electronics assembly, where speed and precision matter most. With no need for drying time, hot melts offer efficiency and cleaner operations compared to solvent-based options. Mahisa Packaging ensures superior formulation standards, focusing on consistent adhesive strength, temperature resistance, and smooth application. By integrating innovative dispenser technology and optimized glue delivery systems, the brand enables industries to improve production output and reduce waste. Designed to enhance sustainability while maintaining performance, Mahisa’s hot melt adhesives are the preferred choice for manufacturers seeking long-lasting, eco-conscious bonding solutions.

Types of hot melt adhesives

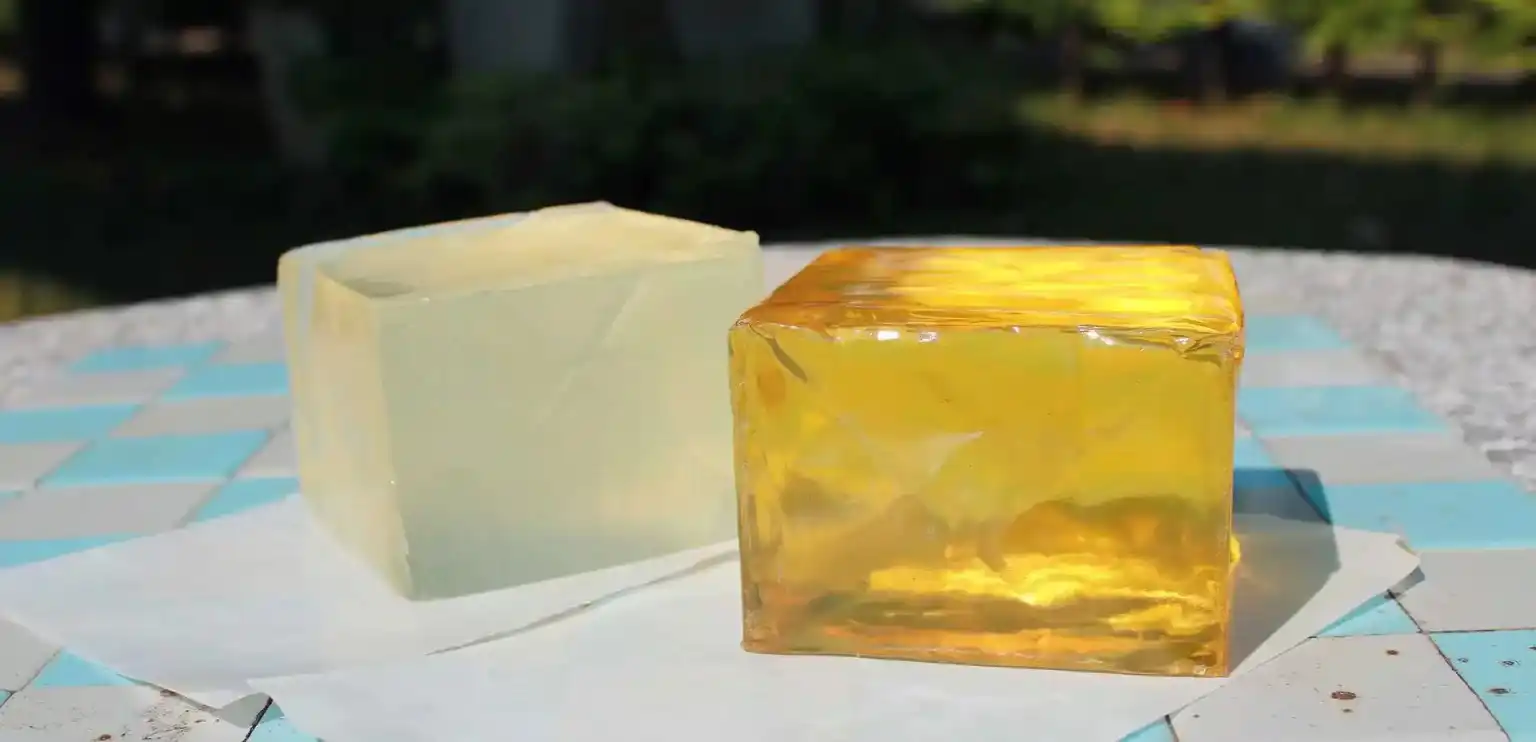

Understanding the Types of Hot Melt Adhesives is essential for selecting the right solution in diverse manufacturing environments. The hot melt adhesives market has expanded significantly due to its ability to provide instant bonding without solvents or water, offering cost-effective and eco-friendly production benefits. Mahisa Packaging specializes in crafting hot melt solutions that meet the evolving demands of industrial applications, from automotive components to flexible packaging. The Benefits of Hot Melt Adhesives include superior flexibility, temperature stability, and consistent adhesive bonding performance across surfaces. EVA, polyamide, and polyolefin-based adhesives each bring unique strengths—ranging from high heat resistance to excellent tackiness and durability. Mahisa Packaging integrates advanced dispensing machinery with precision formulations to deliver reliable results in high-speed production lines. With a focus on sustainability and performance, Mahisa contributes to a greener, more efficient packaging ecosystem while ensuring seamless bonding that enhances product longevity and presentation.

Benefits of Hot Melt Adhesives

The Benefits of Hot Melt Adhesives go beyond fast curing and strong adhesion—they redefine efficiency across industries. Mahisa Packaging, one of the leading Hot melt adhesive manufacturers, provides solutions designed to streamline the adhesive bonding process and support automated production systems. Unlike traditional liquid glues, hot melts require no drying time, making them ideal for continuous manufacturing in packaging, furniture, and automotive applications. The advantages of using hot melt glue include excellent bonding strength, reduced waste, and compatibility with eco-friendly materials. As the hot melt adhesives market in India continues to grow, Mahisa remains at the forefront with innovations that improve thermal stability and long-term performance. Each formulation is engineered to enhance precision, maintain clarity, and ensure durability even under temperature fluctuations. With cutting-edge adhesive systems and a deep understanding of industrial demands, Mahisa Packaging empowers businesses to achieve cleaner operations, higher throughput, and dependable results in every bonding application.

Common uses of hot melt glue

The common uses of hot melt glue highlight its adaptability across packaging, woodworking, textiles, and product assembly. Known for instant adhesion and clean application, these adhesives simplify high-volume production while improving product aesthetics. Mahisa Packaging ensures every formulation offers exceptional adhesive quality, catering to industries that demand both speed and precision. The Benefits of Hot Melt Adhesives include solvent-free bonding, low waste generation, and reduced maintenance requirements in automated lines. With expertise in the hot melt adhesive manufacturing process, Mahisa develops durable formulations suitable for diverse substrates, ensuring reliable performance in varying environmental conditions. Among the Types of hot melt adhesives, EVA-based glues are valued for flexibility, while polyamide and polyolefin blends provide enhanced temperature resistance. Combining innovation and craftsmanship, Mahisa Packaging delivers adhesive systems that balance performance with sustainability, making them indispensable for businesses seeking long-term, efficient, and eco-conscious bonding solutions.

Hot melt glue advantages

The hot melt glue advantages make it an indispensable choice for industries demanding rapid, durable, and clean bonding. As one of India’s leading Hot melt adhesive manufacturers, Mahisa Packaging delivers precision-engineered solutions designed for consistency and efficiency. Understanding the Types of hot melt adhesives—including EVA, polyamide, and polyolefin—helps industries select the right product based on substrate compatibility and thermal needs. Each adhesive is formulated for strong, flexible bonding across paper, plastic, metal, and textiles. The hot melt adhesive composition involves thermoplastic polymers, tackifiers, and stabilizers that ensure superior melt flow and adhesion performance. By continuously improving hot melt adhesives formulation, Mahisa Packaging provides products that optimize productivity and minimize downtime. Their adhesives perform exceptionally in automated lines where reliability and speed are critical, offering both environmental and operational benefits. With a commitment to innovation, Mahisa ensures every formulation meets global standards of strength, quality, and sustainability.

Hot melt adhesive manufacturers

As trusted Hot melt adhesive manufacturers, Mahisa Packaging stands out for delivering premium bonding solutions backed by advanced technology and consistent adhesive quality. The Benefits of Hot Melt Adhesives include instant setting time, solvent-free formulation, and strong adhesion across varied surfaces like plastic, cardboard, and fabric. By perfecting the adhesive manufacturing process, Mahisa ensures each product offers excellent temperature resistance and durability in both manual and automated applications. The hot melt adhesives market continues to expand due to rising demand in packaging, automotive, and construction sectors that rely on efficient, eco-friendly glues. Mahisa’s innovations help businesses achieve cleaner production and higher throughput while reducing waste and energy use. Each adhesive is formulated for stability and precision, ensuring smooth flow and reliable bonding. With a strong focus on quality, sustainability, and performance, Mahisa Packaging continues to lead India’s adhesive industry with solutions tailored to meet the diverse needs of modern manufacturing.

Why Choose Hot Melt Adhesives from Mahisa Packaging?

How Do Hot Melt Adhesives Work?

Types of Hot Melt Adhesives We Offer

1. Ethylene Vinyl Acetate (EVA) Hot Melt Adhesives

2. Polyolefin Hot Melt Adhesives

3. Polyamide Hot Melt Adhesives

4. Pressure-Sensitive Hot Melt Adhesives

5. Polyurethane Reactive (PUR) Hot Melt Adhesives

Benefits of Choosing Hot Melt Adhesives

1. Fast Setting Time for Increased Production Efficiency

2. Superior Bonding Strength

3. Cost-Effective and Eco-Friendly

4. Versatile Application on Various Materials

5. Moisture and Chemical Resistance

Industries We Supply with Hot Melt Adhesives

1. Hot Melt Adhesives for Packaging Industry

2. Hot Melt Adhesives for Woodworking and Furniture

3. Hot Melt Adhesives for Electronics and Automotive Industry

4. Hot Melt Adhesives for Bookbinding and Printing

5. Hot Melt Adhesives for Medical and Hygiene Applications

How to Select the Right Hot Melt Adhesive

When choosing a hot melt glue adhesive for manufacturing, consider the following factors:

Ensure the adhesive bonds well with your substrate.

Choose high-temperature resistant hot melt adhesives for demanding conditions.

Select adhesives with optimal working time and flow properties.

Evaluate the adhesive’s shear strength, peel strength, and flexibility.

Innovations in Hot Melt Adhesive Technology

1. Bio-Based Hot Melt Adhesives

2. Advanced Performance Adhesives

3. Low-Temperature Hot Melt Adhesives

Why Choose Mahisa Packaging for Hot Melt Adhesives?

FAQ's

What is hot melt adhesive?

Types of hot melt glue?

What is hot melt glue made of?

What are the advantages of hot melt glue?

How does hot melt glue work?

What is hot melt glue used for?

Hot melt glue is used extensively in packaging, woodworking, bookbinding, product assembly, and textiles. It’s ideal for applications requiring rapid bonding and versatility. Common uses include sealing cartons, attaching labels, assembling furniture components, bonding fabrics, and securing wires in electronics. Its fast setting time makes it efficient for high-volume production.

How strong is hot melt glue?

What are the common uses of hot melt glue?

What materials does hot melt glue bond well with?

Blogs You May Like..