1. Small Manufacturers & Workshops –

Ideal for businesses that require controlled adhesive bonding processes without investing in automated packaging machinery.

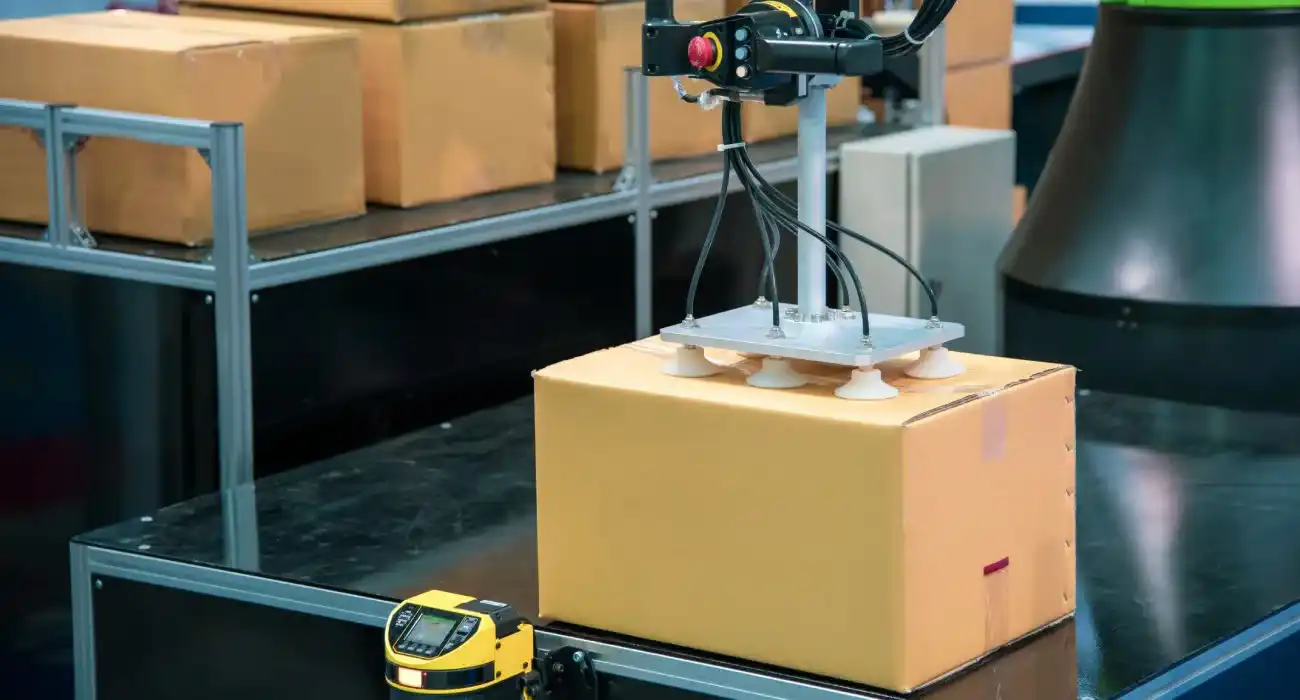

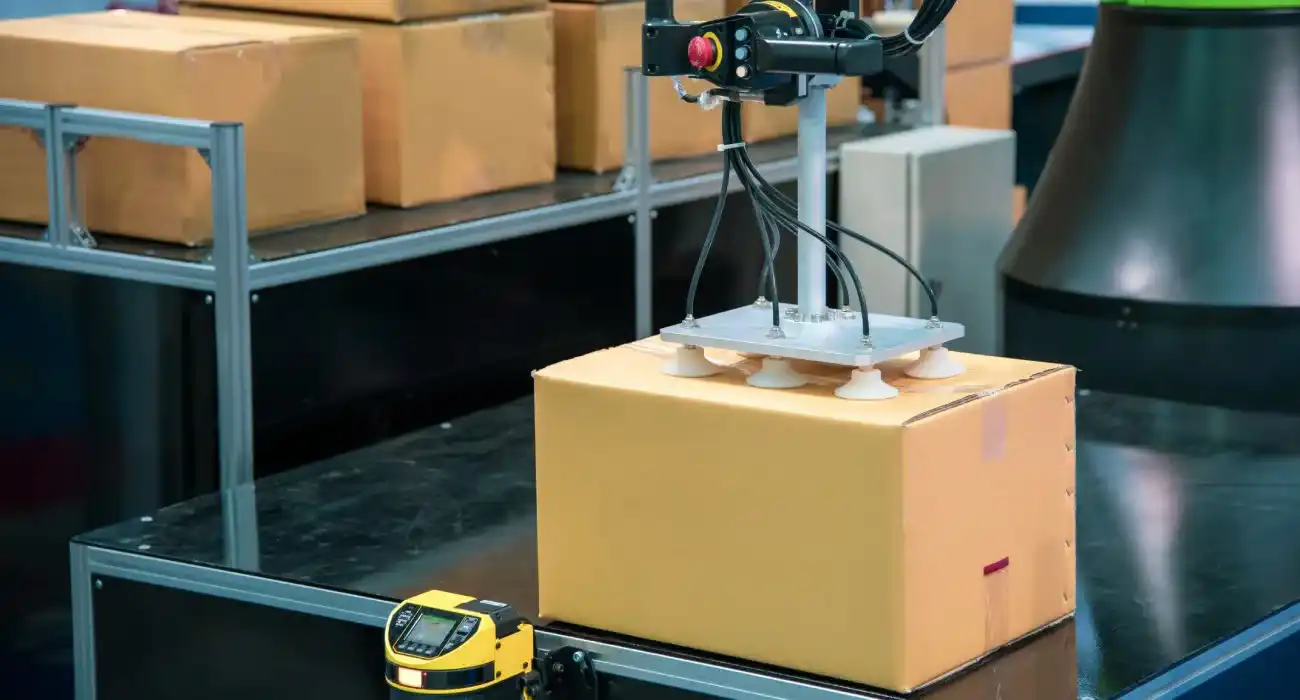

2. Packaging Industry Professionals –

Useful for sealing cartons, assembling boxes, and securing labels in the packaging industry.

3. Woodworkers & Furniture Makers –

Essential for precise gluing processes in cabinetry, veneer application, and wood joinery.

4. Electronics Assemblers –

Helps in applying adhesives with accuracy in circuit boards, sensors, and micro-components.

5. Automotive & Aerospace Technicians –

Used for bonding small parts where glue properties like flexibility and strength are critical.

6. DIY Enthusiasts & Hobbyists –

Perfect for crafting, repairs, and personal projects requiring a steady adhesive flow.

7. Shoe & Leather Goods Manufacturers –

Ensures precise adhesive bonding processes for durability and aesthetics.

8. Medical Device Manufacturers –

Needed for assembling small medical components where accuracy in the gluing process is crucial.

1. Cost-Effective Solution –

Ideal for businesses that don’t require high-end packaging machinery, reducing operational costs.

2. Precision in Adhesive Bonding –

Ensures controlled gluing processes, minimizing waste and improving product quality.

3. Versatility –

Suitable for various industries, including packaging industry, woodworking, electronics, and automotive applications.

4. Easy to Use & Maintain –

No complex setup required, making it a user-friendly tool for professionals and DIY enthusiasts.

5. Consistent Glue Application –

Provides a steady adhesive flow, ensuring strong bonds and enhancing glue properties for durability.

6. Reduces Material Waste –

Dispenses only the required amount of adhesive, preventing excess usage and improving efficiency.

7. Flexibility in Application –

Works with different types of adhesives, making it a valuable tool in diverse adhesive bonding processes.

8. Portable & Compact –

Unlike large packaging machinery, manual dispensers are lightweight and easy to transport.

9. Enhanced Control –

Allows users to adjust pressure and flow, ensuring accuracy in gluing processes for delicate or intricate work.

When it comes to precision glue application in industries like packaging, woodworking, and manufacturing, choosing the right glue dispenser is essential. Two of the best manual glue dispensing units in India, offered by Mahisa Packaging, are the Ecoplus Manual Glue Dispenser and the Ecostar Box Gluing Machine. These dispensers provide efficiency, ease of use, and consistency in the gluing process, making them ideal for businesses that require reliable glue dispensing solutions.

a. Ergonomic design for easy manual operation

b. Consistent gluing process with reduced adhesive waste

c. Compatible with various types of adhesives

a. Suitable for small to medium-scale applications

a. Packaging industry, bookbinding, carton sealing

a. Manual glue dispenser with a roller-based application system

a. Designed specifically for the packaging industry

b. Roller-based glue dispensing for uniform adhesive application

c. Reduces glue wastage and enhances productivity

a. Ideal for medium to large-scale packaging operations

a. Packaging industry, box manufacturing, printing and binding

a. Semi-automatic gluing machine with a robust frame for industrial use

Choosing the right manual glue dispenser can significantly improve efficiency, precision, and cost-effectiveness in various industries. Whether you’re in the packaging industry, woodworking, electronics, or DIY crafts, a reliable glue dispensing unit ensures accurate glue application while minimizing waste.

If you’re looking for a high-quality glue dispenser to optimize your adhesive bonding process, explore Mahisa’s range of gluing machines for a seamless and efficient workflow.