Packaging machine manufacturing in India has undergone a remarkable transformation, adapting to technological advancements, industry demands, and sustainability goals. Earlier, packaging processes relied heavily on manual labor and semi-automatic machines, limiting efficiency and scalability.

Today, modern packaging machines cater to diverse sectors, including food, pharmaceuticals, and e- commerce, meeting global standards for quality and safety. As the packaging industry continues to expand, Indian manufacturers are focusing on innovation, cost-effectiveness, and high-performance machinery to stay competitive in both domestic and international markets.

The packaging market in India is experiencing rapid growth, driven by automation, sustainability, and technological advancements. As industries seek innovative solutions, packaging machine manufacturers

are focusing on efficiency, precision, and eco-friendly practices. With the increasing demand for high-speed, cost-effective, and customizable packaging solutions, new trends are shaping the future of packaging machinery in India. Here are the five key trends transforming the industry:

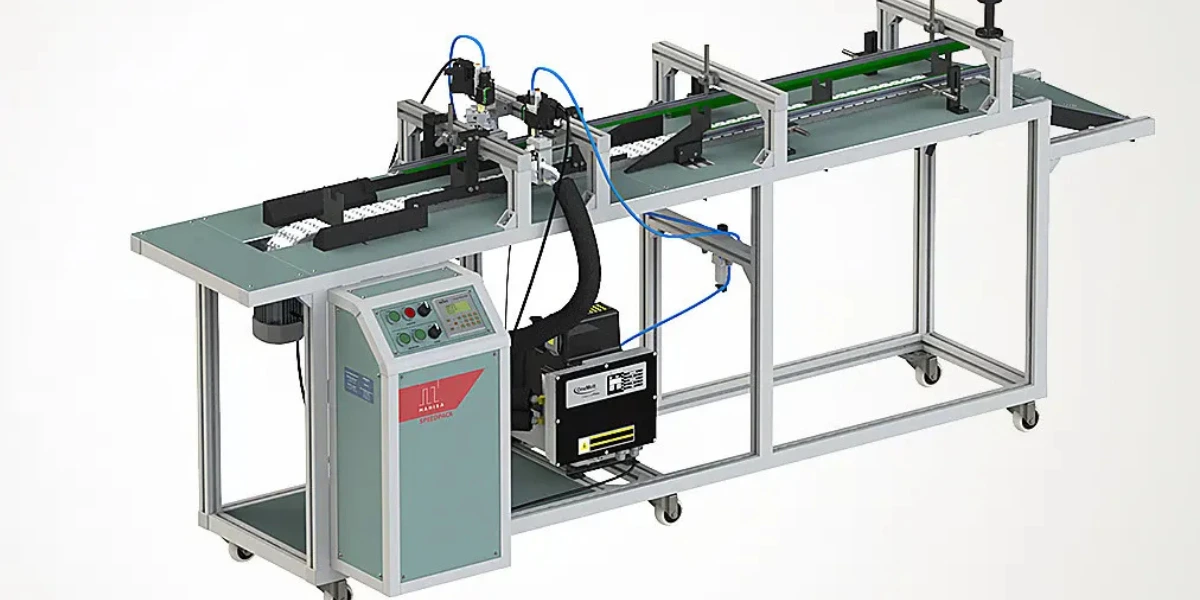

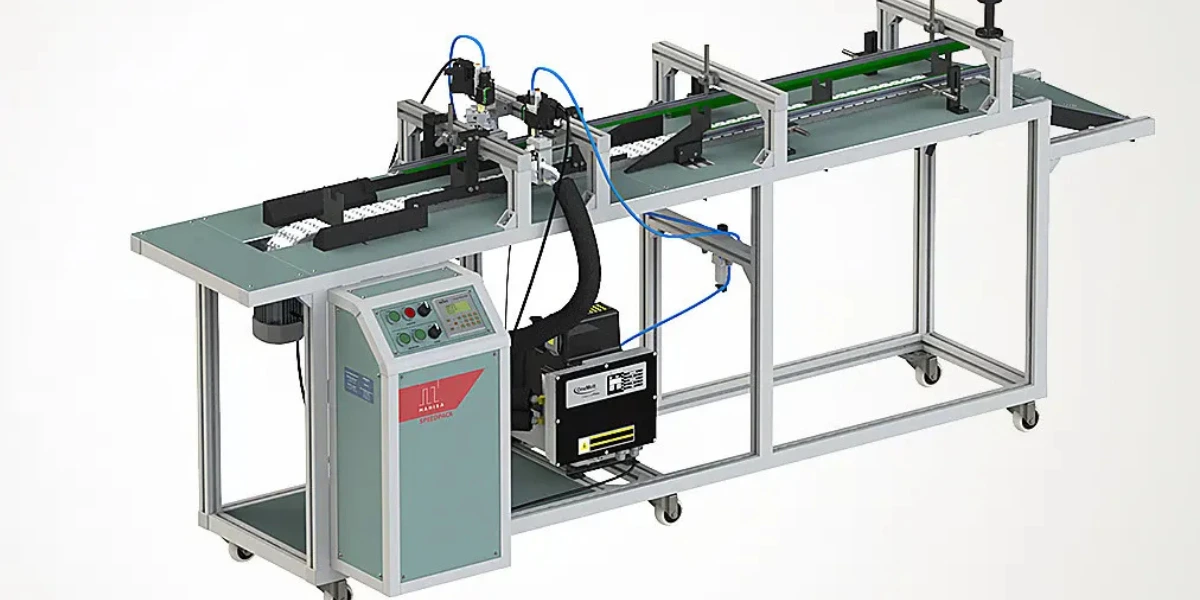

The rise of automation in packaging is revolutionizing the packaging market, with smart technologies enhancing efficiency, accuracy, and productivity. Modern smart automation systems incorporate IoT integration services, AI, and robotics to optimize packaging processes, reducing manual intervention and minimizing errors. These smart machines enable real-time monitoring,

predictive maintenance, and data-driven decision-making, ensuring seamless operations and cost savings. The IoT integration market is rapidly growing, allowing packaging manufacturers to connect machines, streamline production lines, and improve traceability. As demand for high-speed, precision- based packaging solutions increases, advanced packaging machinery with smart automation is becoming essential for industries to stay competitive and meet evolving consumer expectations.

The sustainable packaging market is rapidly growing as businesses embrace eco-conscious practices and prioritize reducing environmental impact. Modern packaging machinery is now designed to support sustainable materials for packaging, such as biodegradable, recyclable, and compostable options. This shift towards eco-friendly solutions aligns with the broader sustainable concept that

promotes minimizing waste and energy consumption. By incorporating these materials, packaging manufacturers are meeting consumer demand for greener products while adhering to stringent

regulations. Additionally, the importance of packaging extends beyond protection—it plays a critical role in marketing, influencing consumer decisions through appealing features of packaging in marketing. As industries move towards more sustainable packaging options, the use of advanced machinery that supports these materials is crucial for businesses aiming to stay competitive and environmentally responsible in today’s market.High-Speed & Customization Capabilities – Demand for faster, flexible, and modular machines is rising to cater to diverse industries.

The growth of digital printing and smart labeling technologies is transforming the packaging industry, offering businesses innovative ways to enhance branding and product authentication. The digital printing process allows for high-quality, cost-effective, and customizable designs, making it easier for companies to produce vibrant packaging with intricate graphics. With the rise of digital printing machines, packaging manufacturers can achieve faster turnaround times and greater flexibility in printing labels, reducing the need for traditional printing plates and processes. Furthermore, digital label printing machines are equipped with track-and-trace technologies, enabling companies to monitor products throughout the supply chain, ensuring authenticity and preventing counterfeiting. This innovation not only boosts brand recognition but also provides consumers with valuable product information, strengthening customer trust and engagement. The integration of these technologies is helping businesses stay competitive by enhancing their packaging and improving overall product safety.

Several industries in India are rapidly embracing advanced packaging machinery to enhance efficiency, sustainability, and automation. With cutting-edge machinery and equipment, businesses are improving product safety, reducing waste, and meeting global packaging standards.

1. Food & Beverage Industry –

Automated packaging machinery in the food and beverage sector enhances production efficiency and reduces labor costs. With high-speed filling, sealing, and labeling technologies, manufacturers can meet the increasing demand for packaged foods, dairy, and beverages. These systems ensure consistency and hygiene, critical for food safety while optimizing the packaging process to minimize waste and improve throughput.

2. Pharmaceutical & Healthcare –

The pharmaceutical industry relies on advanced blister packing, sterilized filling, and track-and-trace solutions to ensure the integrity of medicines. These technologies help prevent contamination, meet stringent regulatory requirements, and offer better protection for sensitive products. Enhanced packaging machinery also plays a key role in child- resistant and tamper-evident packaging, crucial for consumer safety and compliance with health standards.

3. E-commerce & Retail –

The rapid growth of e-commerce demands smarter packaging solutions. Automated sorting, printing, and flexible packaging technologies streamline the packing process, ensuring quick, accurate, and cost-effective packaging for online orders. These innovations cater to the need for protective, lightweight, and customizable packaging that can handle the increasing volume of products shipped directly to consumers, enhancing the overall customer experience.

4. Cosmetics & Personal Care –

High-precision machinery in the cosmetics and personal care industry ensures that products such as beauty creams, lotions, and fragrances are securely packaged. Automated solutions allow for tamper-proof packaging that maintains product integrity and prevents contamination. In addition, machinery with customizable designs ensures that packaging is visually appealing, helping brands differentiate themselves in a highly competitive market.

5. Agro & FMCG Industry –

Sustainable packaging innovations in the agro and FMCG sectors help reduce environmental impact while improving product shelf life. Eco-friendly materials and cost- effective packaging solutions not only cut down on waste but also protect products from spoilage, especially in the case of perishables. These advancements allow businesses to meet growing consumer demand for sustainability while ensuring that products reach consumers in optimal condition.

These industries continue to drive innovation in packaging machinery, ensuring efficiency, sustainability, and market competitiveness.

The adoption of advanced packaging machinery is transforming the packaging industry, offering efficiency, precision, and sustainability. Modern machinery and equipment integrate automation, IoT, and AI to streamline operations, ensuring businesses stay competitive. Here are the key benefits:

1. Increased Efficiency & Speed –

Automated systems enhance production speed, reducing manual labor and errors.

2. Cost Savings –

Advanced packaging machinery minimizes material wastage and operational costs, improving profitability.

3. Enhanced Product Safety & Quality –

Cutting-edge sealing, sterilization, and inspection technologies ensure product integrity and compliance with industry standards.

4. Sustainability & Eco-Friendly Solutions –

New-age machines support biodegradable, recyclable, and minimal-waste packaging materials.

5. Customization & Flexibility –

Smart machines offer adaptable solutions for different packaging designs, sizes, and materials, catering to diverse industry needs.

By leveraging the latest machinery and equipment, businesses can enhance productivity, reduce waste, and meet evolving consumer demands.

Investing in the right packaging machinery is crucial for businesses looking to enhance efficiency, reduce costs, and improve product quality. With a variety of machinery and equipment available, choosing the right one requires careful evaluation. Here are the key factors to consider:

1. Production Capacity & Speed –

Ensure the machine meets your required output and can handle high- speed packaging efficiently.

2. Compatibility with Packaging Materials –

Check if the machine supports different materials like plastic, paper, or eco-friendly options.

3. Automation & Technology Integration –

Look for features like IoT, AI, and smart controls to enhance accuracy and reduce manual intervention.

4. Machine Durability & Maintenance –

Opt for robust, easy-to-maintain equipment with readily available spare parts.

5. Regulatory Compliance & Safety Standards –

Ensure the machine meets industry standards for hygiene, food safety, and product integrity.

Selecting the right packaging machine ensures long-term efficiency, cost savings, and seamless operations in any industry.

Choosing the right packaging machinery is a critical investment for businesses aiming to enhance efficiency, reduce costs, and stay competitive in the evolving packaging market in India. With advancements in automation, sustainability, and smart technology, modern machinery and equipment offer improved speed, precision, and flexibility. However, regular packaging machine maintenance is essential to ensure optimal performance, minimize downtime, and extend the machine’s lifespan.

By considering factors like production capacity, material compatibility, and compliance with industry standards, businesses can ensure long-term operational success. As packaging machine manufacturers continue to innovate, adopting the latest technologies and maintaining equipment properly will help industries streamline processes, improve product safety, and meet growing consumer demands.