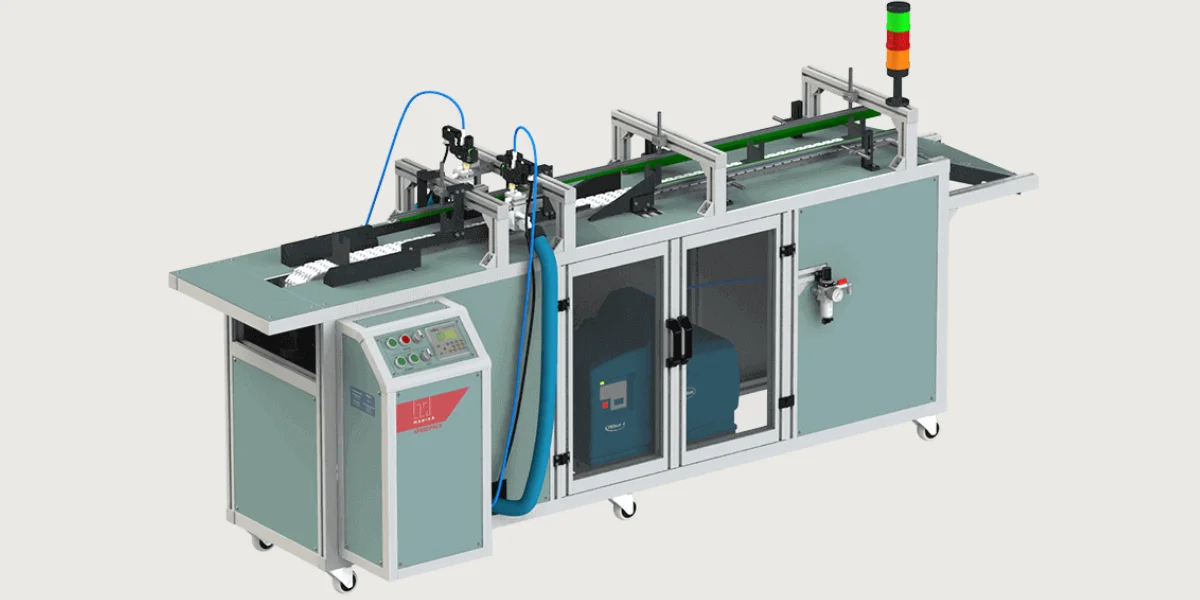

Speedpack Pasting Machine:

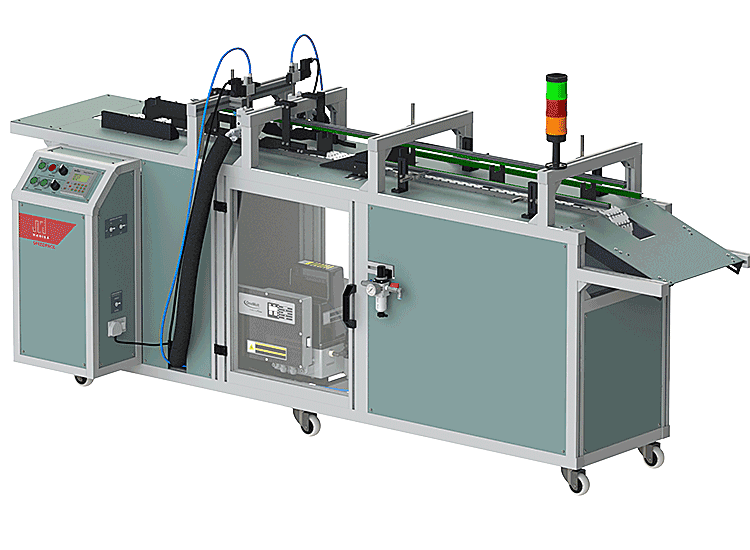

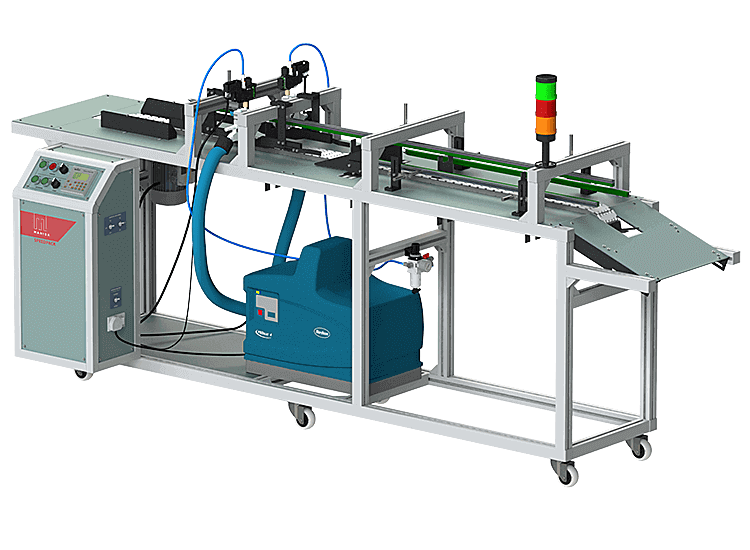

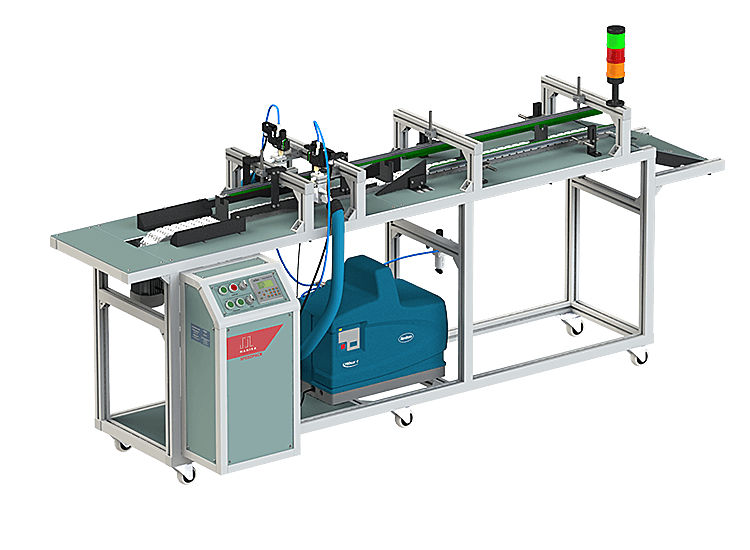

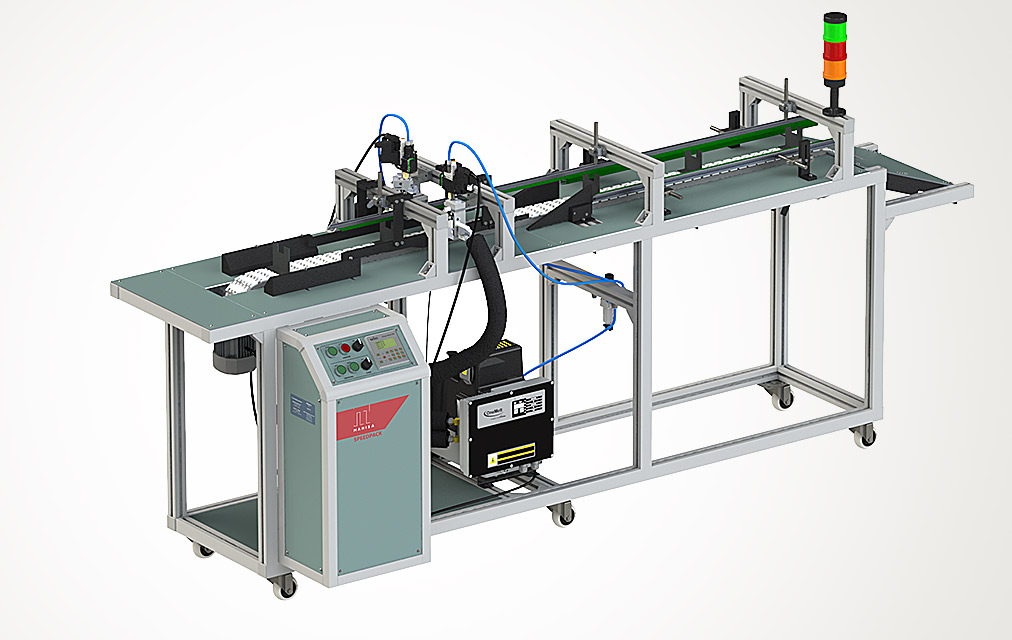

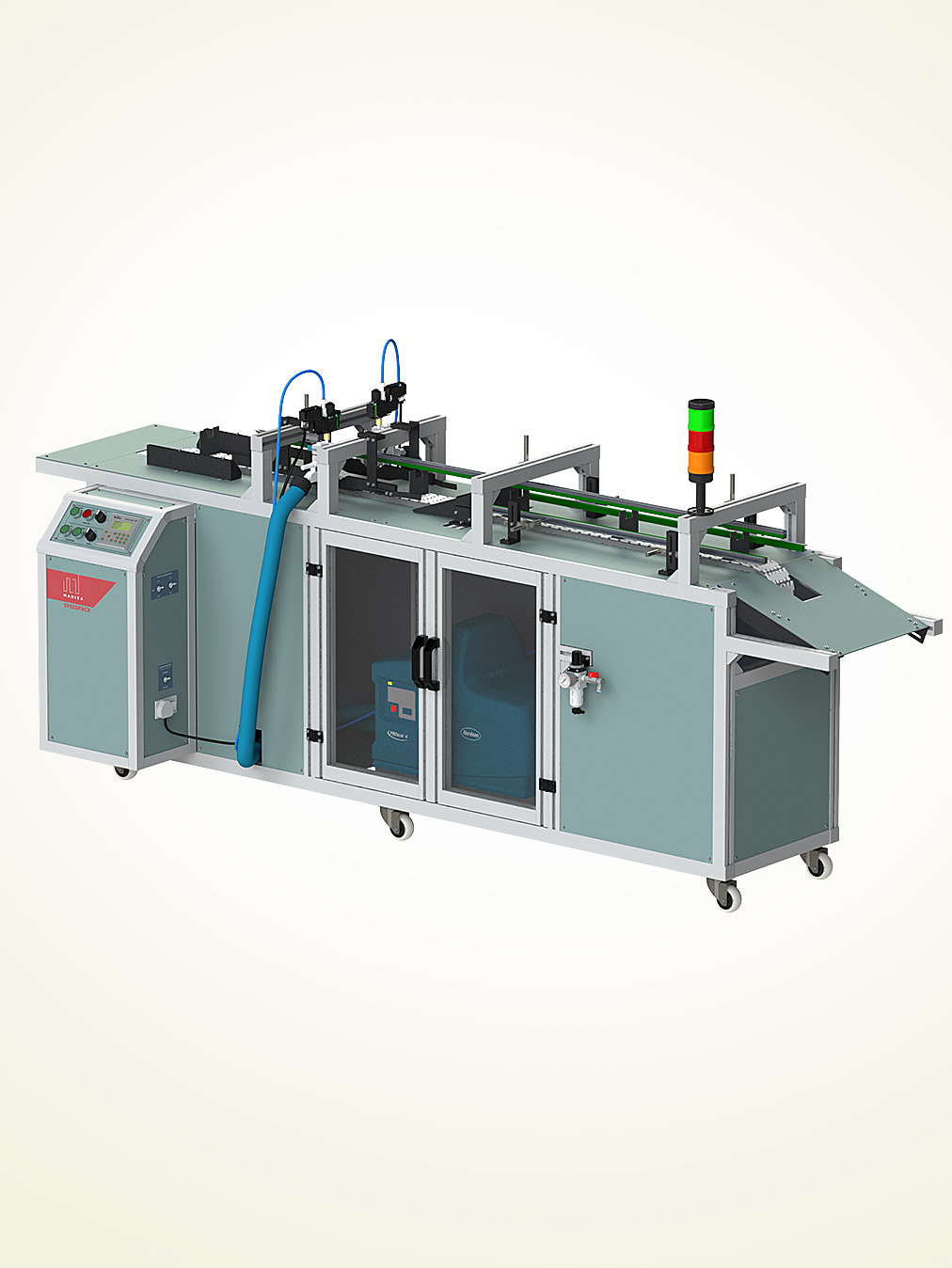

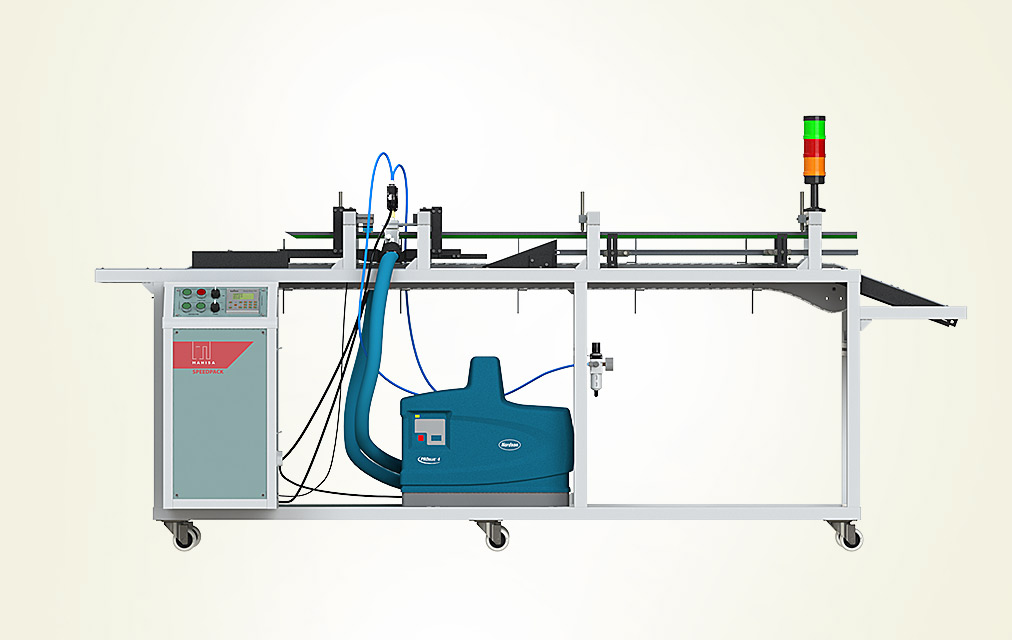

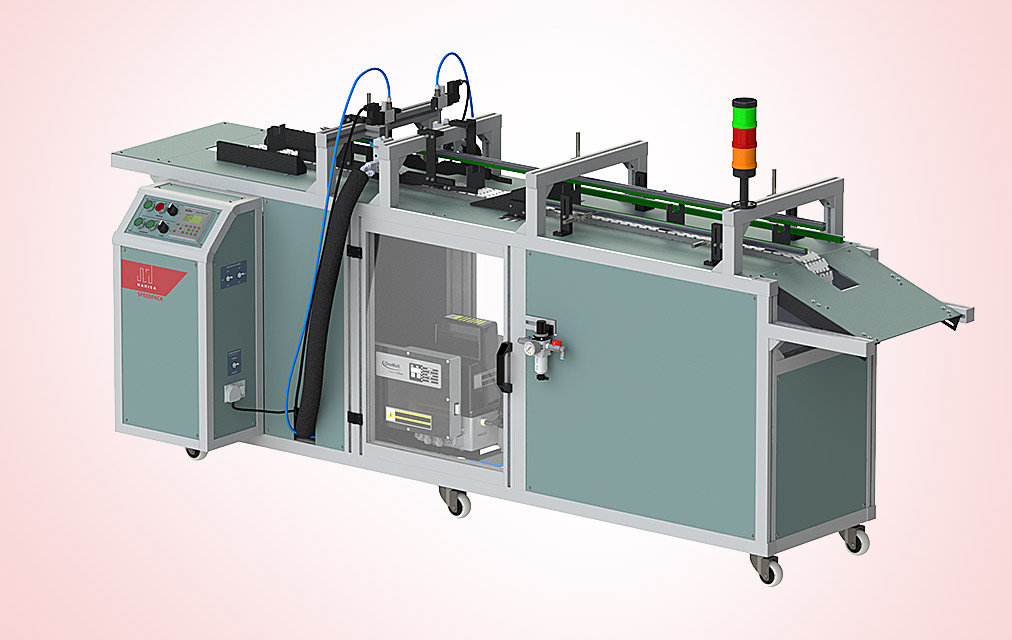

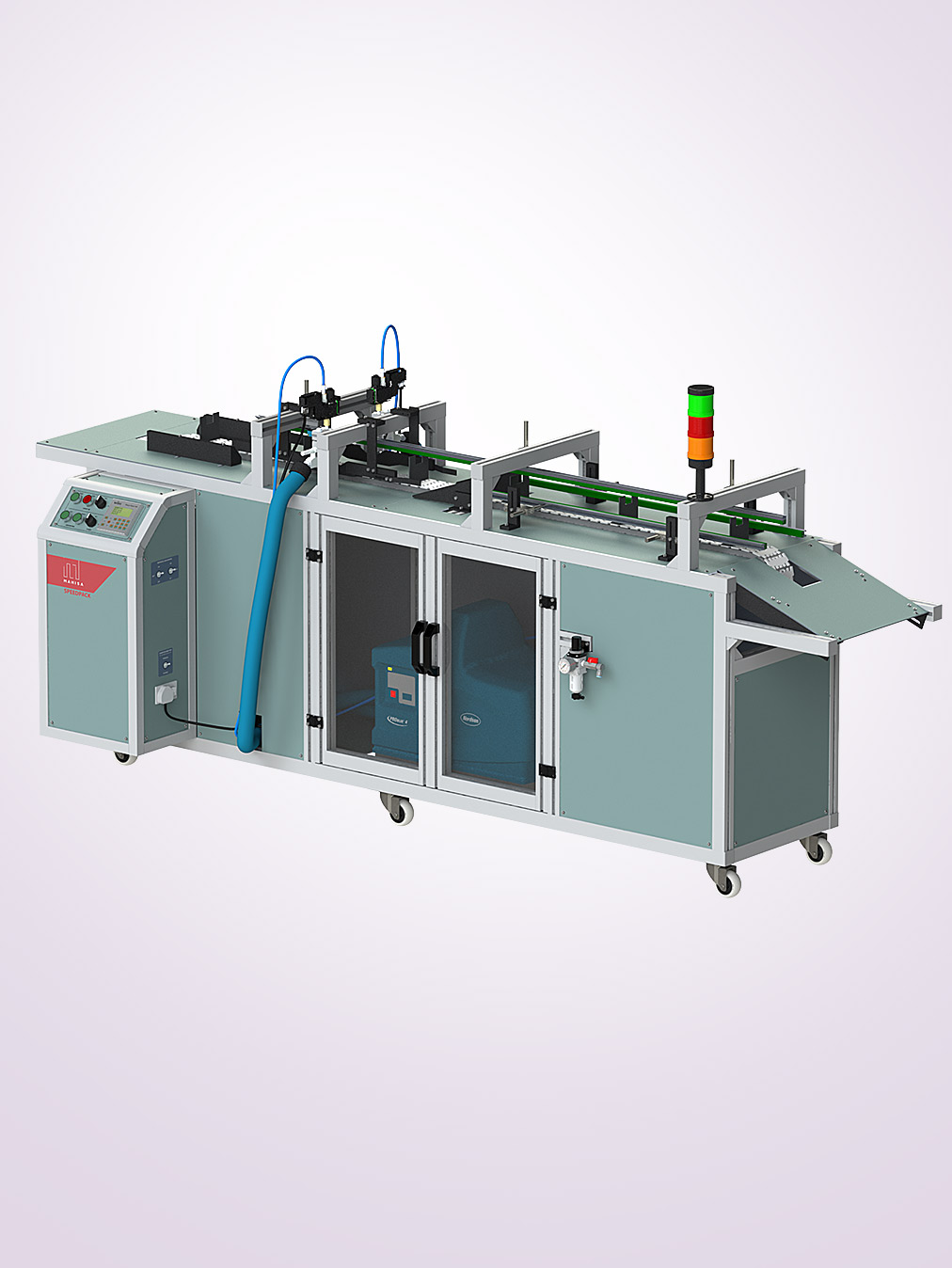

The Speedpack Pasting Machine by Mahisa is a premier mono carton side pasting machine designed to bridge the gap between manual labor and full automation. This high-speed glue machine is specifically engineered for the sealing of rectangular mono cartons using advanced hot melt glue dispensing technology. Capable of processing 60 cartons per minute, it serves as a robust glue dispensing machine that ensures consistent glue bonding. It is the ideal gluing machine for businesses looking to enhance production quality and efficiency.Corrugated Box Flap Pasting Machine

As a heavy-duty corrugated box flap pasting machine, the Speedpack offers unparalleled reliability for diverse packaging needs. This side flap pasting machine utilizes a precision glue dispenser to apply adhesive to various board grades accurately. By integrating a glue application system that features Nordson melters, it functions as a high-performance Glue Pasting Machine. Whether you are sealing lightweight cartons or requiring a durable corrugated box flap pasting machine, this system ensures a tamper-evident, industrial-grade seal every time.Automatic Flap Pasting Machine

Transitioning to an automatic flap pasting machine allows for a seamless “plug-and-play” experience in high-volume environments. This automatic flap pasting machine features a PLC with an in-built HMI for integrated pattern control, allowing for glue dispensing in precise dots or lines. As leading Pasting Machine Manufacturers, Mahisa has designed this Flap Pasting Machine to require minimal maintenance. It stands out as a low-cost, high-capacity glue dispensing machine that can be easily operated by semi-skilled workers.Box Pasting Machine

The Speedpack box pasting machine is a versatile turnkey solution suited for a vast array of industries. From food items like masalas and cereals to pharmaceutical mono carton packaging, this box pasting machine adapts to your specific needs perfectly. Its ability to function as a mono carton side pasting machine makes it essential for packaging house wire coils and industrial bearings. With a fast 15-20 minute changeover time, it remains the most flexible box pasting machine for multi-product lines.Carton Pasting Machine

Every carton pasting machine in the Speedpack line is equipped with world-class hot melt glue dispensing units. These systems utilize piston pumps to handle a wide range of adhesive viscosities, ensuring the carton pasting machine never suffers from clogs or downtime. By choosing this Carton Pasting Machine, you benefit from the best glue application technology available. It provides a clean, efficient glue bonding process that is far superior to traditional manual glue machine methods or hand-gluing.Gluing Machine

Investing in a Mahisa gluing machine means investing in a decade of trouble-free operation. This gluing machine features minimal wear-and-tear components, making it a sustainable choice for high-volume mono carton packaging. As a specialized glue dispenser, it eliminates adhesive waste while maximizing daily output. Whether used as a side flap pasting machine or a primary flap pasting machine, its robust design ensures it remains a cornerstone of your production line, consistently delivering high-quality, reliable glue dispensing.starts here!

For the sealing of rectangular mono cartons using hot-melt adhesive

What is the Speedpack Pasting Machine?

Key Features of the Speedpack Gluing Machine

Achieve an impressive production rate of up to 60 cartons per minute, significantly outperforming manual side flap pasting machine methods.

Equipped with a Nordson hot-melt adhesive dispensing system (including OneMelt, ProBlue, or Mesa melters), the machine ensures zero wastage through a precise glue dispenser.

The system can be customized to process variable carton sizes. Guide settings for size changes are user-friendly and can be executed in just 15–20 minutes.

Designed for longevity, this box pasting machine features minimal wear-and-tear components, often performing for over 10 years with basic maintenance.

Featuring a PLC with an in-built HMI, the glue dispensing machine allows for integrated pattern control, enabling you to dispense glue as dots or lines with surgical precision.

Advanced Hot Melt Glue Technology

Industrial Applications: Who is it for?

Perfect for sealing cartons of spices (masalas), cereals, ready-to-eat meals, frozen foods, and bakery products.

Ensures tamper-evident and hygienic sealing for medicine mono cartons.

Widely used for packaging house wire coils, aluminum foils, and garbage bags.

Provides a robust packaging solution for heavy or precision items like bearings and automotive parts.

Why Choose Mahisa's Speedpack?

Hot-melt adhesive dispensing systems

Technical Specifications

2 to 4-liter options.

Two 6 or 8 ft. hoses connected to precision heads.

Air-Open / Spring-Close Ball & Seat module.

PLC-activated sensor control for precise glue application.

In-built batch and master counter for inventory tracking.

1. Hassle free operation with reduced manual labour for reduced costs and time

2. Simple controls to ensure easy operation with minimal supervision

3. Zero wastage

4. Low maintenance costs

5. Output speed of up to 60 cartons per minute

6. Custom designed as per requirements – can run inner cartons of various sizes on a single piece of equipment

7. Nordson OneMelt, ProBlue, or Mesa melters

8. 2 to 4 litre tank capacity options with two 6 or 8 ft. hoses, each connected to one applicator head

9. Non-stick coated tank with open top access allows easy, clean filling

10. Piston pump with a viscosity range of 800 – 10000 cps

11. Air-Open / Spring-Close Ball & Seat module design

12. PLC with in-built HMI

13. Glue dispensing activation/control using a sensor and a PLC program

14. Integrated pattern control dispense glue as dots or lines with precise control

15. In-built batch and master counter

• Electrical Service: 230 VAC, 1 phase, 50 Hz

• Conveyor: Modular plastic chain conveyor with aluminium frame

• Conveyor width options: 65mm, 85mm, 105mm, 150mm

• Output Capability: Up to 60 cartons per minute

• Cartons size ranges :

• For systems with 65mm wide conveyor - Min:70mm X 40mm X 20mm H | Max: 150mm X 150mm X 70mm H

• For systems with 85mm wide conveyor - Min: 90mm X 40mm X 20mm H | Max: 180mm X 180mm X 75mm H

• For systems with 105mm wide conveyor - Min: 110mm X 40mm X 20mm H | Max: 210mm X 210mm X 75mm H

• For systems with 150mm wide conveyor - Min: 155mm X 40mm X 20mm H | Max: 250mm X 250mm X 75mm H

• These are approx. dimensions of cartons. Each system is customised as per requirements. Sizes that can be run on a single equipment can only be confirmed after receiving carton samples.

• There are various carton design requirements to be considered before designing a system. Please consult our team for the same.

• Viscosity range: 800 – 10,000 cps

• Air pressure while running: 7 – 6.9 bar

• dimensions: 2700mm L x 650mm W x 1200mm H

This equipment is best suited for the packing and sealing of FMCG products usually packed in cartons, such as food items (masalas, spices, ready-to-eat, ready-to-cook, cereals, frozen food, bakery products), pharmaceuticals, house wire coils, aluminium foils, garbage bags, and industrial goods such as bearings, among others.

Features

1. Hassle free operation with reduced manual labour for reduced costs and time

2. Simple controls to ensure easy operation with minimal supervision

3. Zero wastage

4. Low maintenance costs

5. Output speed of up to 60 cartons per minute

6. Custom designed as per requirements – can run inner cartons of various sizes on a single piece of equipment

7. Nordson OneMelt, ProBlue, or Mesa melters

8. 2 to 4 litre tank capacity options with two 6 or 8 ft. hoses, each connected to one applicator head

9. Non-stick coated tank with open top access allows easy, clean filling

10. Piston pump with a viscosity range of 800 – 10000 cps

11. Air-Open / Spring-Close Ball & Seat module design

12. PLC with in-built HMI

13. Glue dispensing activation/control using a sensor and a PLC program

14. Integrated pattern control dispense glue as dots or lines with precise control

15. In-built batch and master counter

Technical Specifications

• Electrical Service: 230 VAC, 1 phase, 50 Hz

• Conveyor: Modular plastic chain conveyor with aluminium frame

• Conveyor width options: 65mm, 85mm, 105mm, 150mm

• Output Capability: Up to 60 cartons per minute

• Cartons size ranges :

• For systems with 65mm wide conveyor - Min:70mm X 40mm X 20mm H | Max: 150mm X 150mm X 70mm H

• For systems with 85mm wide conveyor - Min: 90mm X 40mm X 20mm H | Max: 180mm X 180mm X 75mm H

• For systems with 105mm wide conveyor - Min: 110mm X 40mm X 20mm H | Max: 210mm X 210mm X 75mm H

• For systems with 150mm wide conveyor - Min: 155mm X 40mm X 20mm H | Max: 250mm X 250mm X 75mm H

• These are approx. dimensions of cartons. Each system is customised as per requirements. Sizes that can be run on a single equipment can only be confirmed after receiving carton samples.

• There are various carton design requirements to be considered before designing a system. Please consult our team for the same.

• Viscosity range: 800 – 10,000 cps

• Air pressure while running: 7 – 6.9 bar

• dimensions: 2700mm L x 650mm W x 1200mm H

Industrial Application

This equipment is best suited for the packing and sealing of FMCG products usually packed in cartons, such as food items (masalas, spices, ready-to-eat, ready-to-cook, cereals, frozen food, bakery products), pharmaceuticals, house wire coils, aluminium foils, garbage bags, and industrial goods such as bearings, among others.

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

The Speedpack Pasting Machine by Mahisa is a premier mono carton side pasting machine designed to bridge the gap between manual labor and full automation. This high-speed glue machine is specifically engineered for the sealing of rectangular mono cartons using advanced hot melt glue dispensing technology.

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

The Speedpack Pasting Machine by Mahisa is a premier mono carton side pasting machine designed to bridge the gap between manual labor and full automation. This high-speed glue machine is specifically engineered for the sealing of rectangular mono cartons using advanced hot melt glue dispensing technology.

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

The Speedpack Pasting Machine by Mahisa is a premier mono carton side pasting machine designed to bridge the gap between manual labor and full automation. This high-speed glue machine is specifically engineered for the sealing of rectangular mono cartons using advanced hot melt glue dispensing technology.

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

The Speedpack Pasting Machine by Mahisa is a premier mono carton side pasting machine designed to bridge the gap between manual labor and full automation. This high-speed glue machine is specifically engineered for the sealing of rectangular mono cartons using advanced hot melt glue dispensing technology.

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

The Speedpack Pasting Machine by Mahisa is a premier mono carton side pasting machine designed to bridge the gap between manual labor and full automation. This high-speed glue machine is specifically engineered for the sealing of rectangular mono cartons using advanced hot melt glue dispensing technology.

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

Speedpack Pasting Machine | Automatic Flap Pasting & Sealing

The Speedpack Pasting Machine by Mahisa is a premier mono carton side pasting machine designed to bridge the gap between manual labor and full automation. This high-speed glue machine is specifically engineered for the sealing of rectangular mono cartons using advanced hot melt glue dispensing technology.

What is a Speedpack Pasting Machine?

The Speedpack Pasting Machine is a semi-automatic, continuous 2-flap gluer and folder designed for sealing rectangular mono cartons. It automates the glue bonding and folding process using advanced hot-melt adhesive technology, bridging the gap between manual packing and fully robotic lines.

How many cartons can an automatic flap pasting machine seal per minute?

A high-efficiency automatic flap pasting machine like the Speedpack can achieve an output speed of up to 60 cartons per minute. This allows manufacturers to dramatically increase production throughput compared to manual glue application methods.

Can a box pasting machine handle different carton sizes?

Yes, a versatile box pasting machine is engineered for flexibility. The Speedpack system can be customized to process variable sizes of inner cartons, with guide settings for size changes typically taking only 15 to 20 minutes to execute.

What are the benefits of using a hot melt glue dispensing machine?

Using a hot melt glue dispensing machine ensures superior bond strength, zero wastage, and high-speed operation. It provides precise glue dispensing in the form of dots or lines, which is essential for professional-grade mono carton packaging and tamper-evident sealing.

Which industries use a mono carton side pasting machine?

A mono carton side pasting machine is widely used in the FMCG, pharmaceutical, and consumer goods sectors. Common applications include packaging for spices, frozen foods, bakery products, house wire coils, and industrial bearings.

Is the Speedpack Glue Pasting Machine easy to maintain?

Yes, the Speedpack Glue Pasting Machine is designed for "plug-and-play" operation with minimal wear-and-tear components. When properly maintained, these systems are built to perform for over 10 years, even when operated by semi-skilled workers.

Blogs You May Like..