Understanding Gluing Machines in Packaging: A Key to Efficiency

Understanding Gluing Machines in Packaging:

A Key to Efficiency

Understanding Gluing Machines in Packaging: A Key to Efficiency

Understanding Gluing Machines in Packaging:

A Key to Efficiency

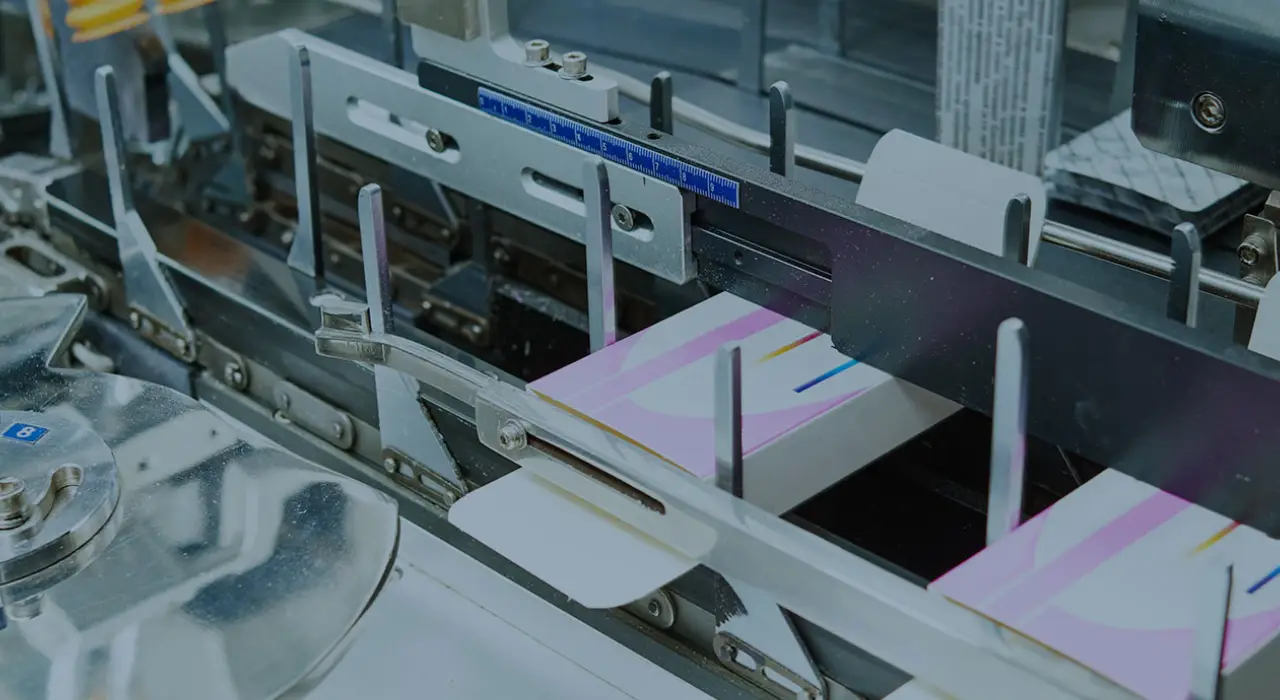

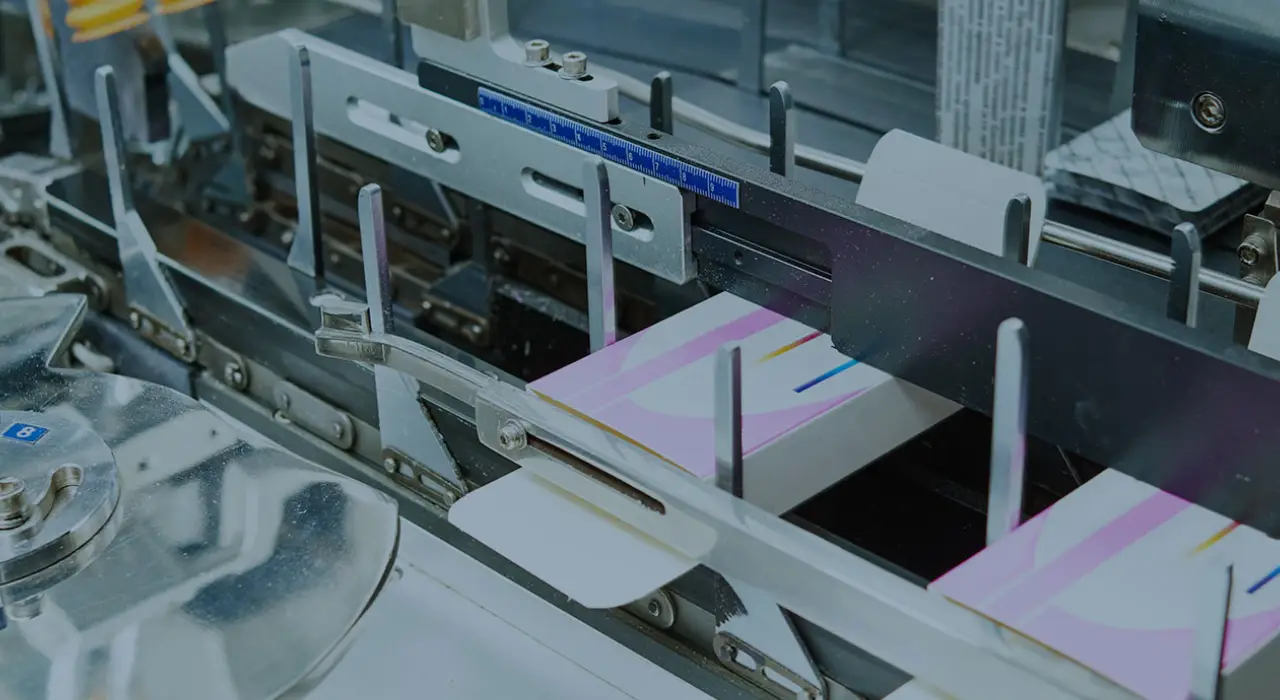

Leading packaging machine manufacturers in India offer advanced gluing solutions tailored to different industry needs. These machines integrate precise glue application techniques, using glue dispensers that control adhesive flow to reduce waste and improve adhesion. From hot melt to cold glue systems, manufacturers provide options that suit diverse packaging requirements.

Benefits of Gluing Machines in Packaging and Manufacturing

1. Enhanced Efficiency and Speed

2. Consistent and Precise Glue Application

3. Cost Savings on Adhesive and Labor

4. Improved Product Quality and Durability

5. Versatility for Different Applications

Modern gluing machines support various adhesives, including hot melt glue, cold glue, and water-based adhesives, making them suitable for different materials like cardboard, paper, plastic, and even wood. Industries such as food packaging, bookbinding, furniture, and automotive components all benefit from these adaptable machines.

6. Reduced Waste and Eco-Friendly Operations

7. Increased Safety and Clean Working Environment

Manual Gluing Machines vs. Automated Gluing Machines

Here’s a detailed comparison:

Parameter | Manual Gluing Machine | Automated Gluing Machine |

Operational Environment | Small-scale workshops, artisan studios, low-volume units | Large-scale factories, automated production lines |

Production Capacity | Limited output, labor-intensive, batch- based processing | High-speed output, continuous and large-scale production |

Adhesive Compatibility | Works with basic adhesives like PVA, water-based, and simple hot melts | Supports a wide range, including hot-melt, PUR, solvent-based, and reactive adhesives |

Industry Suitability | Handcrafted packaging, bookbinding, furniture restoration, specialty design | Mass production in FMCG, automotive, electronics, e-commerce, and industrial packaging |

Application Scope | Customized, artistic, and small-batch products | Standardized, high-volume packaging, corrugated boxes, and food-grade packaging |

Different Types of Adhesives Used in Gluing Machines

1. Hot Melt Adhesives

2. Water-Based Adhesives (PVA & Latex Adhesives)

3. Polyurethane (PUR) Adhesives

4. Solvent-Based Adhesives

5. UV-Curable Adhesives

6. Epoxy Adhesives

Conclusion: Choosing the Right Gluing Machine for Your Needs

FAQ

How do I choose the right type of gluing machine for my specific needs?

Consider factors such as the volume of production, types of materials to be glued, and desired output speed when selecting a gluing machine.

Can a gluing machine work with different types of adhesives?

Yes, many gluing machines are designed to be compatible with various types of adhesives such as hot melt, cold glue, and pressure-sensitive adhesives.

What maintenance is required for a gluing machine?

Regular cleaning, lubrication of moving parts, and inspection of components are essential for maintaining the optimal performance of a gluing machine.

How can I troubleshoot common issues with my gluing machine?

Refer to the user manual for troubleshooting tips or contact the manufacturer’s customer support for assistance in diagnosing and resolving any problems.

Is training necessary to operate a gluing machine effectively?

While some basic operation instructions may be included with the machine, formal training or guidance from experienced operators can help improve efficiency and prevent errors.

Can a gluing machine be customized to meet specific requirements?

Some manufacturers offer customization options such as additional features, specialized nozzles, or adjustable settings to tailor the gluing machine to your unique needs.

Are there safety precautions I should follow when using a gluing machine?

Always wear appropriate personal protective equipment (PPE) such as gloves and safety glasses when operating a gluing machine to prevent accidents or injuries.

What is the typical lifespan of a gluing machine?

The lifespan of a gluing machine can vary depending on usage frequency, maintenance practices, and quality of components but with proper care, many machines can last several years before requiring replacement or major repairs.

Mahisa Packaging Systems LLP

Office Address :

Service & Spares :

Sales Inquiry :

Sales phone: +91 98210 49426

+91 84510 70625

+91 72089 76891

Sales email: sales@mahisa.com

Social Links :

Need Help? Chat with us