Ecostar Box Gluing Machine

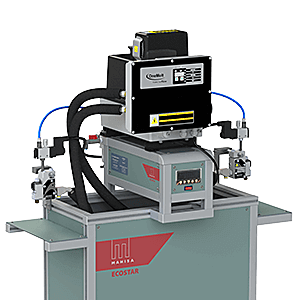

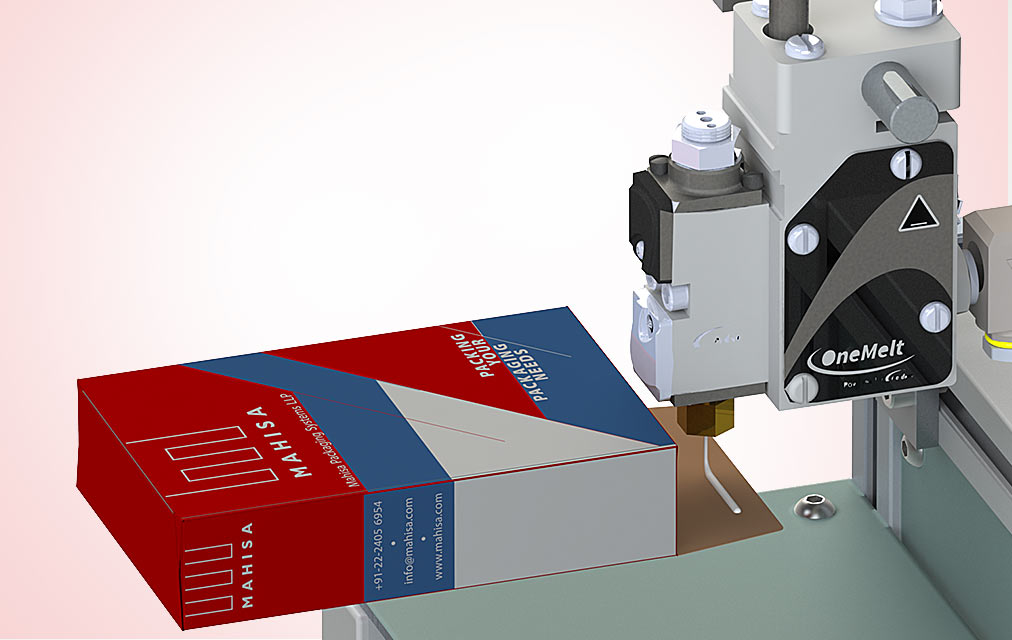

The Ecostar Box Gluing Machine by Mahisa is a premier turnkey solution for businesses looking to upgrade their adhesive application. As a leading Gluing Machine Manufacturer, Mahisa has engineered the EcoStar to handle compact product lines with precision. By integrating world-class melters from Nordson or Robatech with advanced local controls, this system ensures high-quality bonding for small to medium volumes. It is the perfect entry point for those transitioning from manual tapes to professional-grade hot-melt adhesive systems, offering a robust, reliable, and cost-effective packaging solution.Gluing Machine For Boxes

Choosing the right Gluing Machine for Boxes is critical for maintaining structural integrity and professional aesthetics. The EcoStar is designed specifically for versatility, allowing it to handle various substrates like paper-board and corrugated materials. Unlike traditional methods, this system provides consistent application, ensuring every box is sealed with industrial-strength precision. This gluing machine is optimized for an output of up to 10,000 pieces per day, making it a vital asset for manufacturers of shoes, candles, and electronics who require a durable and high-performing bonding solution.Manual Box Gluing Machine

The EcoStar stands out as a user-friendly manual box gluing machine that requires minimal training. Its plug-and-play design allows unskilled or semi-skilled workers to operate the equipment with ease, significantly reducing labor complexities. The system features two 8 ft. hoses and applicator heads, providing the flexibility needed for manual maneuvering around complex shapes. For operations looking to dramatically increase production efficiency while maintaining a low-cost entry point, this manual box gluing setup offers the perfect balance of human control and industrial-grade adhesive technology.Carton Box Gluing

In the realm of carton box gluing, precision and speed are paramount. The EcoStar system streamlines the process by replacing messy water-based adhesives and inefficient handheld glue guns. Capable of processing 1,500–1,600 parts per hour, it ensures that your carton sealing operations never hit a bottleneck. The use of a piston pump allows for a wider range of adhesives, ensuring that even heavy-duty corrugated cartons are bonded securely. This system is the ideal choice for improving the speed and consistency of any carton box gluing production line.Hot Gluing Machine

As a sophisticated hot gluing machine, the EcoStar utilizes advanced thermal controls to maintain the perfect adhesive temperature. This prevents charring and ensures a clean application every time. The integrated PLC and HMI allow users to dispense glue as precise dots or lines, which minimizes waste and lowers overall material costs. Whether you are bonding plastic, foam, or paper, this hot gluing machine provides a sustainable and efficient alternative to traditional bonding, making it a cornerstone for modern, high-quality packaging workflows across various industrial sectors.Packing Box Machine

Every packing box machine in a production facility must be reliable and low-maintenance. The EcoStar is built to last, often performing for over 10 years when properly serviced. Its 2-liter non-stick coated tank and open-top access make refilling quick and clean, reducing downtime. By implementing this system into your packaging industry workflow, you ensure a “zero-wastage” environment. The EcoStar’s ability to adapt to different mounting configurations makes it a flexible packing box machine that grows with your business needs, from small batches to high-volume daily targets.Glue Dispenser

The EcoStar serves as a high-precision glue dispenser and glue dispensing hub for specialized assembly tasks. From bottle cap assembly to chemical duster manufacturing, its “Air-Open / Spring-Close” module design ensures a clean cut-off with every trigger. This glue dispenser is compatible with adhesives up to 10,000cps, providing the versatility needed for diverse industrial applications. Controlled via a foot-operated switch or sensor, the EcoStar offers unmatched accuracy in glue dispensing, ensuring that your products are bonded with the highest level of reliability and professional finish.

Manual hot-melt adhesive dispensing

EcoStar

Manual hot-melt adhesive dispensing

Revolutionizing Manual Glue Dispensing

Features of the EcoStar Ecostar Box Gluing Machine

1. High-Quality Melters and Advanced Controls

2. Versatile and Efficient Design

3. User-Friendly & Low Maintenance

4. Technical Excellence

2-liter non-stick coated tank with easy top-access filling.

Equipped with two 8 ft. hoses, each connected to a dedicated applicator head.

Air-Open / Spring-Close Ball & Seat module design ensures clean cut-offs.

Glue activation via foot-operated switch, sensor, or PLC program.

Applications Across the Packaging Industry

Ensuring structural integrity for retail packaging.

Heavy-duty bonding for shipping containers.

Ideal for bottle/flask cap assembly and scented candle manufacturing.

Efficiently handles foam, plastics, shoe polish containers, and chemical scrubbers.

Why Choose EcoStar for Your Packing Box Machine Needs?

Understanding EcoStar better!

1. Fast & consistent gluing

2. Quick & easy installation

3. Simple controls to ensure easy operation with minimal supervision

4. Zero wastage.

5. Low maintenance costs.

6. 2 litre tank with two 8 ft. hoses, each connected to one applicator head

7. Non-stick coated tank with open top access allows easy, clean filling

8. Air-Open / Spring-Close Ball & Seat module design

9. Application-tailored mounting of the applicator head.

10. PLC with in-built HMI

11. Glue dispensing activation/control using a foot-operated switch, sensor or PLC program

12. Integrated pattern control dispense glue as dots or lines with precise control

13. In-built batch and master counter

• Electrical Service: 230 VAC, 1 phase, 50 Hz.

• Output Capability: 2 hose/applicator pairs

• Heating Time: 30 minutes

• Melt Rate: 1kg/hour

• Tank Capacity (Volume): 2L

• Viscosity range: 800 – 10,000 cps

• Air pressure while running: 7 – 6.9 bar

• Control temperature Range: 110 – 190 °C

• Dimensions: 1000mm L x 550mm D x 1450mm H

1. This equipment is best suited for small products that can be handled by hand. Product bonding requiring an output of up to 10,000 pieces per day can use these hot-melt adhesive dispensing systems. EcoStar can dispense adhesives with up to 10,000cps.

2. These systems can be used in various industries requiring product bonding with hot-melt adhesives, such as carton sealing, paperboard, and corrugated products manufacturing, corrugated carton manufacturing, bottle/flask caps assembly, foam, and plastic bonding, such as in shoe polish, shoe shines, chemical dusters & scrubbers, and scented candles manufacturing, among others.

Features

1. Fast & consistent gluing

2. Quick & easy installation

3. Simple controls to ensure easy operation with minimal supervision

4. Zero wastage.

5. Low maintenance costs.

6. 2 litre tank with two 8 ft. hoses, each connected to one applicator head

7. Non-stick coated tank with open top access allows easy, clean filling

8. Air-Open / Spring-Close Ball & Seat module design

9. Application-tailored mounting of the applicator head.

10. PLC with in-built HMI

11. Glue dispensing activation/control using a foot-operated switch, sensor or PLC program

12. Integrated pattern control dispense glue as dots or lines with precise control

13. In-built batch and master counter

Technical Specifications

• Electrical Service: 230 VAC, 1 phase, 50 Hz.

• Output Capability: 2 hose/applicator pairs

• Heating Time: 30 minutes

• Melt Rate: 1kg/hour

• Tank Capacity (Volume): 2L

• Viscosity range: 800 – 10,000 cps

• Air pressure while running: 7 – 6.9 bar

• Control temperature Range: 110 – 190 °C

• Dimensions: 1000mm L x 550mm D x 1450mm H

Industrial Application

1. This equipment is best suited for small products that can be handled by hand. Product bonding requiring an output of up to 10,000 pieces per day can use these hot-melt adhesive dispensing systems. EcoStar can dispense adhesives with up to 10,000cps.

2. These systems can be used in various industries requiring product bonding with hot-melt adhesives, such as carton sealing, paperboard, and corrugated products manufacturing, corrugated carton manufacturing, bottle/flask caps assembly, foam, and plastic bonding, such as in shoe polish, shoe shines, chemical dusters & scrubbers, and scented candles manufacturing, among others.

Ecostar Box Gluing Machine | Manual Carton Glue Dispenser

Ecostar Box Gluing Machine | Manual Carton Glue Dispenser

The Ecostar Box Gluing Machine by Mahisa is a premier turnkey solution for businesses looking to upgrade their adhesive application. As a leading Gluing Machine Manufacturer, Mahisa has engineered the EcoStar to handle compact product lines with precision.

Ecostar Box Gluing Machine | Manual Carton Glue Dispenser

Ecostar Box Gluing Machine | Manual Carton Glue Dispenser

The Ecostar Box Gluing Machine by Mahisa is a premier turnkey solution for businesses looking to upgrade their adhesive application. As a leading Gluing Machine Manufacturer, Mahisa has engineered the EcoStar to handle compact product lines with precision.

FAQ

What is an EcoStar Box Gluing Machine?

The EcoStar Box Gluing Machine is a turnkey hot melt adhesive dispensing system designed for manual applications. It integrates world-class melters (like Nordson) with Mahisa's control systems to provide a high-precision, low-cost solution for carton box gluing and packing box machine operations.

How does a manual box gluing machine improve production?

A manual box gluing machine like the EcoStar replaces slow, traditional methods such as tapes and hand-held hot glue guns. It increases efficiency by allowing operators to process up to 1,600 parts per hour, ensuring consistent bonding, reduced adhesive waste, and professional-grade packaging quality.

What industries use the EcoStar hot gluing machine?

The EcoStar hot gluing machine is widely used in the packaging industry for:

- Carton box gluing and sealing.

- Corrugated box manufacturing.

- Product assembly (bottle caps, foam, and plastic bonding).

- Specialty items like scented candles and chemical scrubbers.

Can the EcoStar glue dispenser handle different adhesives?

Yes. As a versatile glue dispenser, the EcoStar uses a high-performance piston pump capable of dispensing hot-melt adhesives with viscosities up to 10,000cps. This makes it suitable for a wide range of industrial bonding requirements across diverse materials.

Is the EcoStar gluing machine for boxes easy to maintain?

Absolutely. Designed by a leading gluing machine manufacturer, the EcoStar is a plug-and-play system with a non-stick coated tank and minimal wear-and-tear components. With basic regular servicing, this gluing machine can perform reliably for over 10 years in a standard production environment.

What is the daily output of the EcoStar packing box machine?

The EcoStar is optimized for small to medium production volumes. It is best suited for product lines requiring an output of up to 10,000 pieces per day, offering a perfect balance between manual control and industrial speed.

What types of adhesives can be used with EcoStar?

The EcoStar glue dispenser is compatible with a wide range of industrial hot-melt adhesives. Thanks to its robust piston pump system, it can efficiently process adhesives with viscosities up to 10,000cps. This includes EVA, Polyolefin, and PSA (Pressure Sensitive Adhesives) commonly used in the packaging industry.

Can EcoStar be integrated into existing production lines?

Yes, the EcoStar is a highly adaptive hot gluing machine. While it is optimized for manual application, its PLC-based control system and tailored mounting options allow it to be integrated into semi-automated or compact product lines. It can be triggered via a foot-operated switch, sensors, or external PLC programs to match your existing workflow.

What are the compatibility options for EcoStar with different substrates?

As a versatile gluing machine for boxes, the EcoStar offers excellent compatibility across various substrates, including:

- Paper & Cardboard: Ideal for standard carton box gluing and corrugated materials.

- Plastics & Foam: Used in shoe polish, chemical scrubbers, and assembly.

- Specialty Surfaces: Capable of bonding glass (bottle caps), wood, and scented candle containers.

What are the optional accessories available for EcoStar?

To enhance your manual box gluing machine setup, Mahisa offers several optional accessories, including:

- Custom Applicator Heads: Tailored nozzles for specific bead sizes or spray patterns.

- Extended Hoses: Options beyond the standard 8 ft. hoses for larger workspaces.

- Precision Sensors: For automated glue triggering in semi-auto setups.

- Pattern Controllers: Integrated HMIs to dispense precise dots or stitches to reduce glue consumption.

Book an appointment form

to see EcoStar

Blogs You May Like..