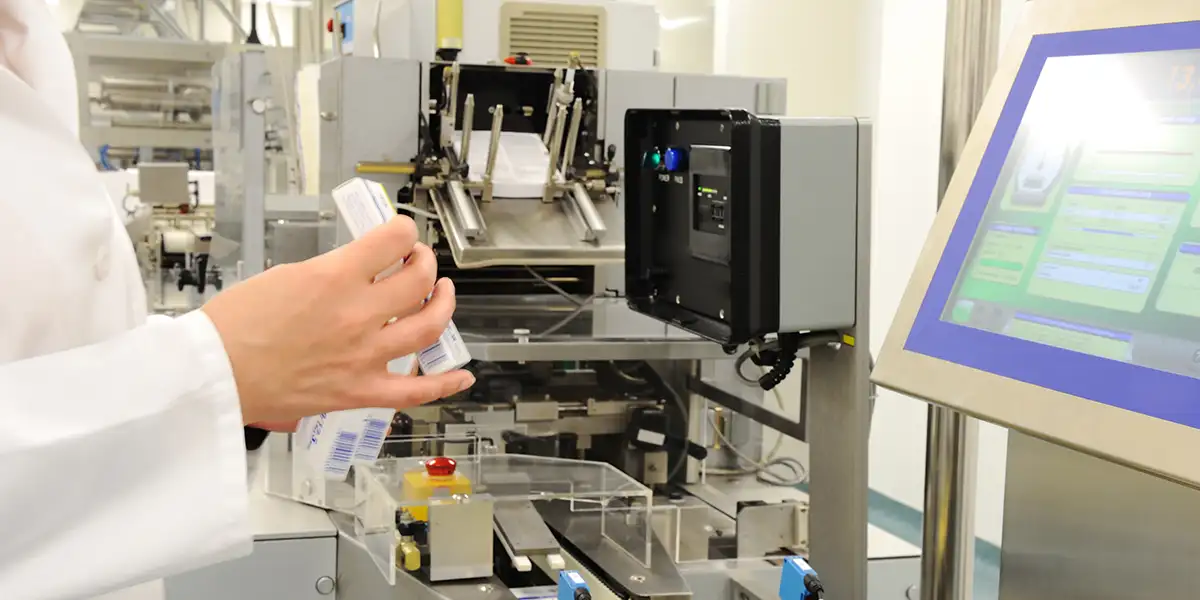

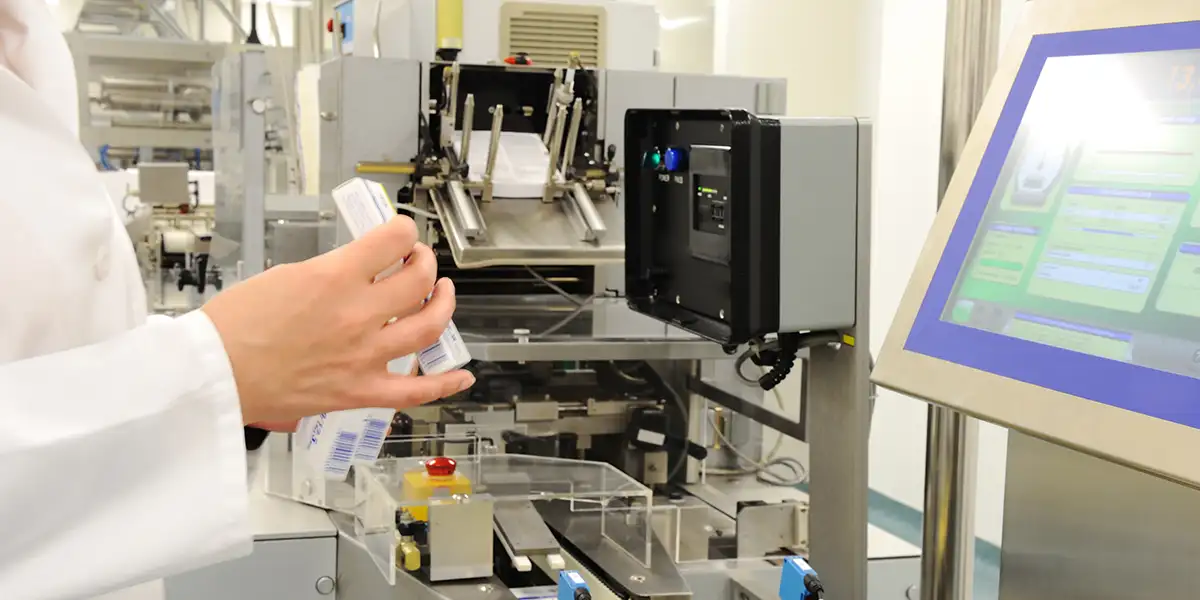

In the packaging industry, efficiency and precision are key to maintaining high production standards. A glue dispensing machine plays a vital role in automating the box sealing process, ensuring durability and consistency. Leading glue dispensing machine manufacturers provide advanced solutions that improve both productivity and packaging quality.

1. High-Speed Performance –

Automates gluing for faster production in packaging machinery.

3. Versatile Application –

Works with different packaging materials, from carton boxes to rigid boxes.

4. Reduced Waste & Cost Efficiency –

Precision glue application minimizes excess usage.

5. Seamless Integration –

Easily integrates with existing packaging machinery for smooth operations.

Gluing machines are essential in the box packaging industry, automating adhesive application for faster and more consistent sealing. These machines use precision glue dispensing systems to apply adhesives efficiently, ensuring strong, durable packaging.

1. Corrugated Boxes –

Used for shipping and storage, requiring strong adhesives for durability.

2. Folding Cartons –

Common in retail and FMCG, benefiting from precise glue application for seamless folding.

3. Rigid Boxes –

High-end packaging for luxury goods, needing even glue distribution for a premium finish.

1. Hot Melt Glue –

Fast-drying, strong adhesion, and ideal for high-speed production lines.

2. Water-Based Glue –

Eco-friendly, cost-effective, and suitable for paperboard cartons.

3. Polyurethane (PU) Adhesive –

Provides flexible bonding, perfect for rigid and specialty boxes.

By integrating glue dispensing machines, manufacturers enhance production efficiency, reduce material waste, and improve the overall quality of packaging.

Using a glue dispensing machine streamlines the box pasting process, ensuring precision and efficiency. Here’s how it works:

a. Flat box blanks are placed on the feeder of the machine.

b. Automated feeding ensures continuous workflow for high-speed production.

a. The glue dispensing machine applies adhesive along pre-set fold lines.

b. Adhesives used: hot melt glue, water-based glue, or PU adhesive, depending on box type.

a. The machine folds the glued sections accurately.

b. Pressure is applied to ensure a firm bond and proper adhesion.

a. Hot glue dispensers ensure fast drying.

b. Water-based glues require brief curing time before handling.

a. Finished boxes are inspected for proper adhesion.

b. Boxes are stacked for packing or shipping.

In the fast-paced world of packaging, choosing the right gluing machine can make all the difference. Whether you’re working with carton boxes, rigid boxes, or specialty packaging, the right machine ensures durability, efficiency, and cost savings. But which one is the better choice – a manual gluing machine or an automated gluing machine? Let’s break it down.

A manual gluing machine is ideal for businesses with small-scale operations or customized packaging needs. It provides:

✓ Full control over glue application for intricate or handcrafted boxes.

✓ Lower initial investment, making it budget-friendly.

✓ Flexibility to work with different types of glue, including water-based and hot melt adhesives.

However, manual machines require skilled labor, take more time, and may lead to inconsistencies in larger productions.

✓ High-speed production, ideal for bulk orders.

✓ Consistent glue application, ensuring strong and reliable box sealing.

✓ Cost efficiency in the long run by reducing labor costs and glue wastage.

✓ Seamless integration with other packaging machinery, enhancing workflow efficiency.

If precision, speed, and scalability are your goals, the automated gluing machine is the clear winner. But for artisanal packaging or small-batch production, a manual gluing machine may still hold its charm. Choose wisely based on your business needs!

In today’s competitive packaging industry, efficiency and precision are key to success. A glue dispensing machine not only enhances production speed but also ensures strong, reliable seals for carton boxes, rigid boxes, and other packaging materials. With the ability to work with various types of glue, from hot melt adhesives to water-based solutions, these machines cater to diverse packaging needs.

For businesses focused on large-scale production, an automated gluing machine offers unmatched speed, consistency, and cost savings. Meanwhile, manual gluing machines remain a viable option for smaller, more customized packaging operations.

By investing in the right packaging machinery from a trusted packaging machine manufacturer, businesses can improve efficiency, reduce waste, and elevate packaging quality. Whether you prioritize speed, flexibility, or cost-effectiveness, the right gluing solution can transform your packaging process and drive long-term success.